Screw pump in the printing industry

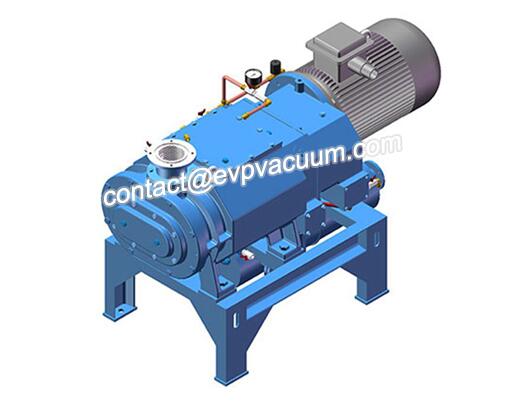

Screw pump (zero maintenance cost, no loss operation, with variable frequency control system)

(in the central vacuum system of printing plant, a product can be used as both vacuum pump and pressure pump, saving the quantity and cost of standby machine)

The production printing and paper industry requires a steady supply of vacuum applications. The production machine applies vacuum to the small holes in the metal drum in which the envelope is fixed and delivered. The higher the vacuum, the greater the fixing force. The need to install (vacuum and low pressure) system upgrades is increasing. For these upgrades, companies with envelope manufacturing machines require oil-free screw vacuum systems to replace their dry blade pumps and luo blowers. Generally speaking, in an envelope factory or a binding factory, the main motivation for upgrading the vacuum system is to save energy. Oil-free screw vacuum systems are superior to other vacuum systems for increasing production speed. For envelope machines, the faster the machine, the greater the need for a better vacuum. As the vacuum level gets deeper and deeper and exceeds -0.6 bar (g), the performance of the dry vane pump and the luo blower cannot meet the requirements. Some customers are now asking for -0.7 bar (g), which means screw vacuum pumps are ideal.

Consistent performance across any vacuum range required for print-like applications. Constant wear and tear of blades with frequent use affects performance and reliability. At the heart of the pump, the time-tested screw element can continue to operate when the blade stops. Size is not limited by technology, so we can provide a system to meet all requirements. Double vacuum bags – engineering challenges a technique used to make composite materials (or “laminates”) called “double vacuum bags”. Because of this technology, extremely light and strong composite materials can be produced and used in high-risk industries, such as the aerospace industry. At the same time of forming the material, the double vacuum bag is formed into a composite material. Laminates are produced by applying the right amount of heat, pressure, and vacuum. This means ensuring a steady flow of heat and vacuum.

With a central vacuum system and integrated monitoring equipment, all key parameters can be checked at any time. Upgrading of vacuum systems in the printing industry all printing plants have applied vacuum technology to some extent, and the discovery of the terrible inefficiency of dry rotary technology for customers has caused more and more customers to rush to upgrade existing vacuum systems. Improvements such as these will be lucrative, especially for the printing industry. Often, the main purpose of upgrading a vacuum system in a printing or binding plant is to save energy. In other cases, reasons to upgrade include increased system stability and productivity. In order to further improve the production efficiency, the requirement of printing system to vacuum system is continuously increased. When the vacuum requirements of the system exceed -0.6bar(g), the performance of the dry rotary vane pump with roots pump unit has reached the bottleneck. For envelope presses, the faster the equipment, the better the vacuum. At present, some customers already need a negative pressure environment of -0.7bar(g), which is the better working range of the screw pump. The products can meet all kinds of pressure requirements in the printing industry. Due to the absence of contact and wear in the pump chamber, VS series products can maintain stability and continuous operation in principle. Vacuum pumps have higher pumping speed than rotary vane pumps, which means that customers no longer need to install many, many small pumping speed vacuum pumps, which is more suitable for mass production.