Vacuum Melting Technology

Vacuum induction metling furnace is one new epuipement in metallurgy industry .It smelt metals and alloys in the crucible which is enclosed in a vacuum chamber with the turbo electricity caused by electromagnetic induction as a heat source.

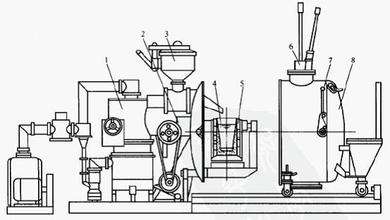

Vacuum induction melting furnace contains three principal parts: furnace, vacuum system, power supply control. The furnace, which offers a space for metallurgy, consists of the following elements: the alloy feeding mechanism, viewing means, sampling means, temperature measuring device, furnace overturning mechanism,ingot mechanism, crucible, sensor, power feeding device and vacuum chamber. The vacuum system including a variety of vacuum pumps, vacuum valves, instrumentation, etc., provides the vacuum which metallurgical production process requires. Power supply control (not shown) is responsible for supplying the necessary energy for smelting process.

Figure 1 vacuum induction melting furnace structure diagram (1- vacuum system; 2-furnace overturning mechanism; 3- feeding mechanism; 4- crucible; 5- sensors; 6- sampling and ramming device; 7- temperature measuring device; 8 – movable furnace)

To get a higher vacuum is a key to design a vacuum induction melting furnace because vacuum has a direct effect on melting process.The vacuum system is made up of mechanical vacuum pump+Roots vacuum pump or mechnical vacuum pump+diffusion vacuum pump. With these vacuum systems, it is easy to get a ulimate vacuum from 10-3Torr to 10-5Torr. However, it is still very difficult to achieve 10-8Torr.

The melting furnace works on induction heating and vacuum melting.

Induction heating principle based primarily on two basic laws of electricity, Faraday’s law of electromagnetic induction and Joule – Lenz’s law(also known as the current thermal effect principle). When the induction furnace gets through to AC current, metal material in the crusible surrounded by induction coils causes induced electromotive force according to Faraday’s law of electromagnetic induction, and induced current in the metal is brought up then due to a closed loop in metal material. This induced current releases the heat on the basis of Joule – Lenz’s law and gets metal material smelt.

There are three main external factors which effect a chemical reaction: temperature, density and pressure. Vacuum melting influences on chemical reactions which gas takes part in by varying the external pressure during the metallurgical process. When the gas mole number in the reaction product gas is greater than that that in reactant, to reduce the system pressure (i.e., increasing vacuum degree) can keep equilibrium reaction moving toward the direction of getting more gaseous substance, and then a more complete reaction is carried out.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)