Silencing check valve installation instructions

Silencing check valve of function characteristics and installation instructions

However, many users know little about the installation and use of silencing check valve.

Silencing check valve is a kind of automatic valve, which mainly depends on the flow of medium itself to open and close the valve disc automatically. The valve is used to prevent medium backflow, reverse rotation of pump and driving motor, and discharge of container medium. It has been widely used in water supply and drainage system, high-rise building pipe network, and has attracted the attention of market users.

Silencing check valve of characteristics

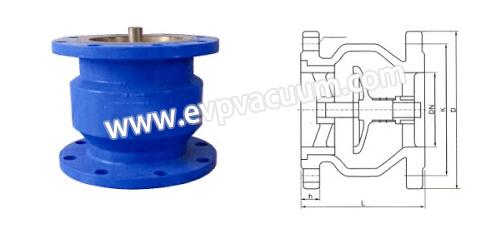

1. The valve disc adopts the “bullet head” shape design, and the valve body adopts the “waist drum” shape design to improve the medium flow direction and reduce the flow resistance coefficient

2. The valve is of short structure. Although the head loss is slightly larger than the lift silent check valve, it is small in size and cheap in price

3. The structure is compact, non-metallic lubricating sleeve is installed between the guide shaft and the guide frame, so the valve disc can be lifted and lowered flexibly without locking

4. The framework type rubber seal ring is directly inlaid on the valve body to avoid the direct erosion of the medium on the sealing ring for a long time, and the service life is obviously prolonged, which is firm and durable

5. The opening and closing stroke of valve disc is short, which can effectively prevent water hammer

6. It is suitable for water supply and drainage system and high-rise building pipe network. It can be installed at the outlet of the pump with slight structural changes. It can be used as suction bottom valve, but it is not suitable for sewage pipe network.

Silencing check valve of installation method

1. Both ends of the valve passage must be blocked, and there is a dry and ventilated room. If it is stored for a long time, it should be checked for rust.

2. The valve should be cleaned before installation and the defects caused during transportation should be eliminated.

3. Carefully check whether the signs and nameplates on the valve meet the requirements during installation.

4. The valve is installed on the horizontal pipeline with the valve cover upward.

Silencing check valve is a kind of automatic valve, which mainly depends on the flow of medium itself to open and close the valve disc automatically. The valve is used to prevent medium backflow, reverse rotation of pump and driving motor, and discharge of container medium. It has been widely used in water supply and drainage system, high-rise building pipe network, and has attracted the attention of market users.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)