Single stage liquid ring vacuum pump

Our company’s hot single water ring vacuum pump

2BV2 and 2BV6 series water ring vacuum pump/compressor are mainly used to remove explosive gas and work in various flammable and explosive environments. Their performance parameters are the same as 2BV2 and 2BV5 series.

2BV series stainless steel vacuum pump can be used in various occasions with high corrosion resistance requirements and high cleanliness requirements.

According to the working condition of 2BV series stainless steel vacuum pump all flow parts: impeller, disc, pump cover, pump body material can be selected

SUS304 (0 cr18ni9)

SUS316 (0 cr17ni12mo2)

SUS316L (00 cr17ni14mo2)

Stainless steel, pump shaft material: 2Cr13, SUS304 or SUS316L

The mechanical seal USES the import product, the seal may use the fluorine rubber or the polytetrafluoroethylene

2BV series water ring vacuum pump structure and features:

Pump coaxial direct train design, save space, easy to install.

Mechanical seals are standard; eliminates leaks; easy maintenance.

Smooth operation and noise levels can be as low as 62 db

Unified corrosion resistance design, bronze impeller improved pump corrosion resistance, stainless steel is more suitable for more demanding applications

The unique flexible exhaust design allows no over compression, ensuring SKA efficiency within its performance range.

2BV series water ring vacuum pump service scope:

Widely used in petrochemical, pharmaceutical, food, sugar industry and other fields, because in the process of work, the gas compression process is isothermal, so in the compression and suction of flammable and explosive gas, not easy to occur dangerous, its application is more widely.

2BV series water ring vacuum pump product display

Performance parameters:

| Curve No. | Model | Max. suction capacity | Ultimate vacuum mbar(MPa) |

Motor power kW |

Speed r.p.m |

Operating liquidflow rate L/min |

Noise dB(A) |

Weight kg |

|

| m3/min | m3/h | ||||||||

| 60V | 2BV2-060 | 0.45 | 27 | 33mbar (-0.097MPa) |

0.81 | 2840 | 2.5 | 62 | 37 |

| 61V | 2BV2-061 | 0.86 | 52 | 1.45 | 2840 | 2.5 | 65 | 41 | |

| 70V | 2BV2-070 | 1.33 | 80 | 2.35 | 2860 | 3 | 66 | 66 | |

| 71V | 2BV2-071 | 1.83 | 110 | 3.85 | 2880 | 4.7 | 72 | 85 | |

| 110V | 2BV5-110 | 2.75 | 165 | 4 | 1440 | 7.2 | 63 | 120 | |

| 111V | 2BV5-111 | 3.83 | 230 | 5.5 | 1440 | 8.8 | 68 | 150 | |

| 121V | 2BV5-121 | 4.66 | 280 | 7.5 | 1440 | 11 | 69 | 210 | |

| 131V | 2BV5-131 | 6.66 | 400 | 11 | 1460 | 16 | 73 | 280 | |

| 161V | 2BV5-161 | 8.33 | 500 | 15 | 970 | 22 | 74 | 390 | |

| 110V | 2BV6-110 | 2.75 | 165 | 4 | 1440 | 67 | 63 | 150 | |

| 111V | 2BV6-111 | 3.83 | 230 | 5.5 | 1440 | 10 | 68 | 200 | |

| 121V | 2BV6-121 | 4.66 | 280 | 7.5 | 1440 | 12 | 69 | 230 | |

| 131V | 2BV6-131 | 6.66 | 400 | 11 | 1460 | 17 | 73 | 315 | |

| 161V | 2BV6-161 | 8.33 | 500 | 15 | 970 | 23 | 74 | 426 | |

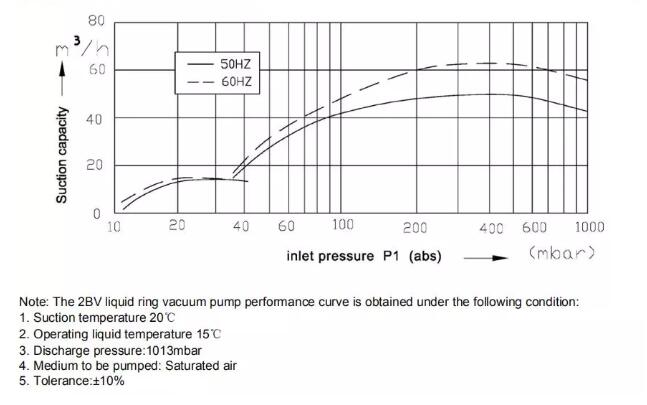

Note: 1. The data listed in the table are measured under the following technical conditions:

Atmospheric pressure 101325Pa (1013mbar)

(2) the water temperature of 15 ℃

(3) sucked in air temperature 20 ℃

(4) air relative humidity 70%

2. The allowable deviation of performance is 10%

Performance curve:

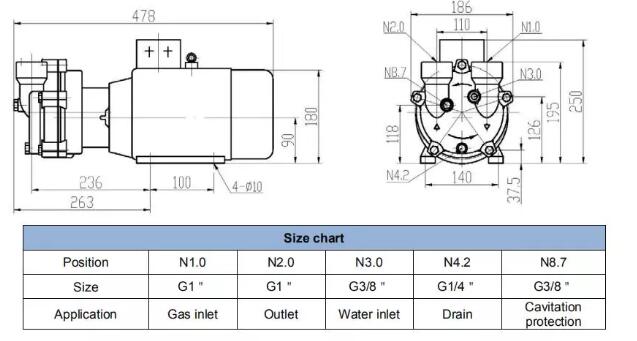

Installation dimension drawing:

SKA2 outline size drawing (unit: mm) :

Equipment installation:

1. Installation of water ring vacuum pump:

When installing water ring vacuum pump and compressor, the mounting surface must be horizontal and installed firmly with bolts through the holes in the bottom corner. In order to prevent welding slag into the vacuum pump during installation, the filter should be installed on the suction pipe.

2, water ring vacuum pump gas-water separator installation

The water ring vacuum pump gas-water separator can be directly installed on the air outlet of the water ring vacuum pump and fixed firmly with bolts. The gas-water separator has a pipeline connected to the pump to supply water demand for the water-ring vacuum pump. The rest of the working water is supplied by the water supply pipe, and the water supply is adjusted by the valve on the pipeline.

The water ring vacuum pump or compressor shall have a check valve on the intake pipe to prevent the water in the vacuum pump or compressor from returning to the system under the pressure of the exhaust pipe during parking.

Start and stop:

1. Start water ring vacuum pump

Water ring vacuum pump long stop pump before starting, must be turned several times by hand, in order to verify that the water ring vacuum pump is not stuck or other damage phenomenon.

The water ring vacuum pump shall be started in the following order (see figure 5).

(1) open the exhaust pipe valve.

(2) start the motor (pay attention to the positive and negative rotation of the motor)

(3) quickly open the water supply pipe in FIG. 5 2. Gradually increase the water supply until the water supply meets the requirements, (should pay attention to do not dry operation vacuum pump).

2. Stop the water ring vacuum pump

Stop the water ring vacuum pump in the following order:

(1) close the valve on the intake pipe (if there is a valve in the intake pipe).

(2) shut down the water supply pipe 2 and quickly shut down the vacuum pump.

(3) the water in the pump chamber should be discharged after stopping the pump, so as to avoid the blade and pump shaft fracture when starting again.

Maintenance:

1, SKA water ring vacuum pump to avoid wear impeller, pump body or stuck impeller, with the gas and working fluid into the pump chamber of dust particles, can be washed away through the SKA water ring vacuum pump pump at the bottom of the rinse port.

2, if using hard water as working fluid, must be softened, or in a certain period of time with the solution to clean the pump.

3, SKA water ring type vacuum pump motor often work bearing high than the surrounding temperature 15 ℃ ~ 20 ℃, high does not allow more than 55 ℃ ~ 60 ℃, the normal work of bearing loading should be 1-2 times a year, cleaning bearing at least once a year, and replace all lubricating oil.

4, SKA water ring vacuum pump mechanical seal, leakage phenomenon, should check the mechanical seal of the dynamic and static ring is damaged, or the seal ring has been aging, such as the above situation, need to replace new parts.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)