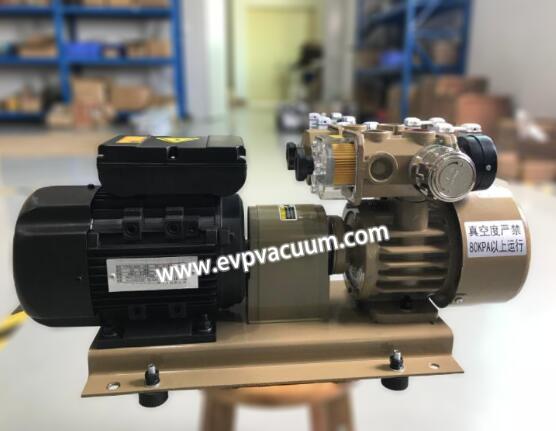

Single stage oil-free vacuum pump

Single stage oil-free vacuum pump for precautions

1. It should have sufficient and good ventilation conditions and an ambient temperature lower than 40 ℃.

2. Clean place without dust and dirt.

3. No water, oil and other liquids will fall on the pump.

4. Not directly exposed to the sun.

5. There is enough surrounding space to facilitate the inspection, maintenance and assembly and disassembly of the pump.

6. The pump must be mounted on a flat surface.

7. It is best to place the pump on a hard foundation similar to concrete. If there is no condition, the pump can also be installed firmly on the steel or wooden frame.

8. The single-stage oil-free vacuum pump must ensure that the pump does not vibrate due to the foundation is not firm.

9. The connecting pipe with the pump should not be too long or smaller than the pump inlet diameter, which will affect the pumping speed. Pay attention to check whether there is air leakage in the vacuum connecting pipe.

10. When connecting wires, attention should be paid to the wiring requirements specified on the motor name plate. Three phase electric pump should pay attention to the motor rotation direction should be consistent with the direction of the marked arrow on the pump.

Environmental protection oil free vacuum pump of notice

(1) The environmental protection oil-free vacuum pump refers to the pressure of the remaining gas in the pumped container. The partial pressure is the factory standard, the total pressure is the auxiliary standard. The thermocouple measures the total pressure of all kinds of steam and permanent gas, while the Maxwell’s meter can only measure the partial pressure of the permanent gas, so there are some differences between the two meters.

(2) The pumping speed of environmental protection oil-free vacuum pump is calculated according to the geometric dimension. At atmospheric pressure, the actual pumping speed is basically consistent with the geometric pumping speed, and the pumping speed has a certain decrease under various pressures.

(3) Temperature rise refers to the difference between the oil temperature at the exhaust valve and the room temperature after the temperature of the environmental protection oil-free vacuum pump is stable.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)