Single stage vacuum pump

Many ta would like to know which is better, single-stage vacuum pump or double-stage vacuum pump. Next, I would like to introduce our company’s single-stage vacuum pump to you. Our company’s best-selling single-stage vacuum pump mainly has two types: single-stage water ring vacuum pump and single-stage rotary vane vacuum pump.

2BE1 series single stage water ring vacuum pump

I. product overview

2be1 type direct water ring vacuum pump is used to pump or compress air and other non-corrosive, insoluble in water, do not contain solid particles of gas, in order to form a vacuum and pressure in the closed container, inhaled gas allowed to mix with a small amount of liquid.

Ii. Application:

2be1 type direct water ring vacuum pump is widely used in machinery, petroleum, chemical, pharmaceutical, food and other industries and other fields, especially suitable for large water pump.

Product display

Technical parameters

| Model | Speed

(Driving mode) |

Shaft power | Motor power | Ultimate

vacuum |

Max. capacity | Weight (excl.

motor) |

|

| r/min | KW | 380V | hpa | M³/hr | M³/min | kg | |

| 2BE1-102 | 1450 (direct)

1750 (V-belt) |

6.0

8.0 |

Y132M-4-7.5

Y160M-4-11 |

33hpa

(-0.097MPa) |

246

290 |

4.1

4.8 |

110 |

| 2BE1-103 | 1450 (direct)

1750 (V-belt) |

8.2

11.1 |

Y160M-4-11

Y160L-4-15 |

33hpa

(-0.097MPa) |

340

412 |

5.7

6.9 |

125 |

| 2BE1-152 | 1450 (direct)

1625 (V-belt) 1750 (V-belt) |

12.5

15.0 17.2 |

Y160L-4-15

Y180M-4-18.5 Y180L-4-22 |

33hpa

(-0.097MPa) |

450

510 535 |

7.5

8.5 8.9 |

175 |

| 2BE1-153 | 1450 (direct)

1100 (V-belt) 1300 (V-belt) 1620 (V-belt) 1750 (V-belt) |

16.3

10.6 13.4 19.6 22.3 |

Y180M-4-18.5

Y160L-4-15 Y180M-4-18.5 Y180L-4-22 Y200L-4-30 |

33hpa

(-0.097MPa) |

600

445 535 648 700 |

10.0

7.4 8.9 10.8 11.7 |

200 |

| 2BE1-202 | 980 (direct)

790 (V-belt) 880 (V-belt) 1100 (V-belt) 1170 (V-belt) 1300 (V-belt) |

18.2

13.4 16.3 23.8 25.7 30 |

Y200L2-6-22

Y180M-4-18.5 Y180M-4-18.5 Y200L-4-30 Y200L-4-30 Y225S-4-37 |

33hpa

(-0.097MPa) |

750

590 670 860 888 950 |

12.5

9.8 11.2 14.3 14.8 15.8 |

460 |

| 2BE1-203 | 980 (direct)

790 (V-belt) 880 (V-belt) 1100 (V-belt) 1170 (V-belt) 1300 (V-belt) |

29.5

21.2 24.8 34 38 42 |

Y250M-6-37

Y200L-4-30 Y200L-4-30 Y225M-4-45 Y225M-4-45 Y250M-4-55 |

33hpa

(-0.097MPa) |

1080

870 980 1210 1320 1390 |

18

14.5 16.3 20.2 22.0 23.2 |

530 |

| 2BE1-252 | 740 (direct)

565 (V-belt) 660 (V-belt) 830 (V-belt) 885 (V-belt) 938 (V-belt) |

38

23.7 31.8 45 54 60 |

Y280M-8-45

Y200L-4-30 Y225S-4-37 Y250M-4-55 Y280S-4-75 Y280S-4-75 |

33hpa

(-0.097MPa) |

1700

1200 1500 1770 2000 2100 |

28.3

20.0 25.0 29.5 33.3 35.0 |

870 |

| 2BE1-253 | 740 (direct)

565 (V-belt) 660 (V-belt) 740 (V-belt) 792 (V-belt) 820 (V-belt) 880 (V-belt) 940 (V-belt) |

54

37.2 45 50.8 60 68 75.1 88 |

Y315M-8-75

Y225M-4-45 Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-75 Y280M-4-90 Y315S-4-110 |

33hpa

(-0.097MPa) |

2450

1690 2100 2340 2560 2640 2780 3050 |

40.8

28.2 35 39 42.7 44 46.3 50.8 |

930 |

| 2BE1-303 | 740 (direct)

590 (direct) 466 (V-belt) 530 (V-belt) 583 (V-belt) 660 (V-belt) 740 (V-belt) |

98

65.5 48 58 64 79.8 96 |

Y315L2-8-110

Y315L2-10-75 Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 |

33hpa

(-0.097MPa) |

4000

3200 2520 2820 3100 3550 3840 |

66.7

53.3 42 47 51.7 59.2 64 |

1700 |

| 2BE1-305 | 740 (direct)

590 (direct) 490 (V-belt) 530 (V-belt) 583 (V-belt) 660 (V-belt) 740 (V-belt) |

108

70 55 61 68 90 110 |

Y355M1-8-132

Y355M1-10-90 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 Y315M-4-132 |

33hpa

(-0.097MPa) |

4520

3750 3150 3380 3700 4090 4550 |

75.3

62.5 52.5 56.4 61.2 68.1 75.8 |

1820 |

| 2BE1-353 | 590 (direct)

390 (V-belt) 425 (V-belt) 464 (V-belt) 530 (V-belt) 560 (V-belt) 620 (V-belt) 660 (V-belt) |

121

63 72 85 95 110 133 152 |

Y355L2-10-160

Y280S-4-75 Y280M-4-90 Y315S-4-110 Y315M-4-110 Y315L1-4-132 Y315L1-4-160 Y315L2-4-185 |

33hpa

(-0.097MPa) |

5300

3580 3700 4100 4620 5000 5500 5850 |

88.3

59.7 61.7 68.3 77.0 83.3 91.7 97.5 |

2300 |

| 2BE1-355 | 590 (direct)

390 (V-belt) 420 (V-belt) 464 (V-belt) 523 (V-belt) 590 (V-belt) 660 (V-belt) |

136

75 80.8 95 113 136 182 |

Y355L2-10-160

Y280M-4-90 Y280-4-90 Y315S-4-110 Y315M-4-132 Y315L1-4-160 Y315L2-4-200 |

33hpa

(-0.097MPa) |

5700

4180 4260 4850 5230 6000 6510 |

95

69.7 71 80.8 87.1 100 108 |

2450 |

| 2BE1-403 | 330 (V-belt)

372 (V-belt) 420 (V-belt) 472 (V-belt) 530 (V-belt) |

98

110 131 160 213 |

Y315M-4-132

Y315M-4-132 Y315L1-4-160 Y315L2-4-200 Y355M2-4-250 |

33hpa

(-0.097MPa) |

4860

5400 6470 7380 8100 |

81

90 107.8 123.0 135.0 |

3750 |

| 2BE1-405 | 330 (V-belt)

372 (V-belt) 420 (V-belt) 472 (V-belt) 530 (V-belt) |

100

118 140 170 216 |

Y315M-4-132

Y315L1-4-160 Y315L2-4-185 Y315L2-4-200 Y355M2-4-250 |

33hpa

(-0.097MPa) |

6000

6700 7500 8350 9450 |

100.0

111.7 125.0 139.2 157.5 |

3900 |

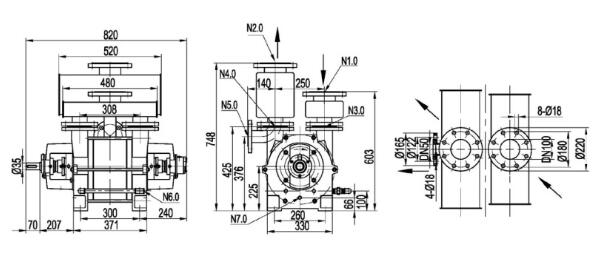

Installation dimensions

Single stage rotary vane vacuum pump working principle

When the rotor rotates in the stator, the volume of the suction space increases gradually and the pumped air bathes the suction space. At the same time the volume of the exhaust space is gradually reduced, the previous cycle has been inhaled gas compression, when the gas pressure is high enough, that is, greater than the oil gravity and the sum of the elastic force of the valve, is pumped gas top exhaust valve, through the oil layer by the exhaust pipe.

Structure and working principle of single stage rotary vane vacuum pump

The extraction process of single stage rotary vane vacuum pump

Several typical positions of rotary vane vacuum pump in the working process:

(1) the rotor blade 1 is in a vertical position and coincides with the fixed tangential point 4 of the rotor and stator, and the suction process has not yet started.

(2) when the rotor 1 turns from point A to A certain Angle, the inspiration space will gradually increase, and the gas will enter the inspiration space through the air inlet from the extracted air.

(3) when blade 1 reaches the horizontal position, blade 2 seals the air inlet, and the gas no longer enters the inspiratory space, and the inspiratory capacity reaches the maximum.

(4) as the rotor continues to rotate, the gas enclosed between the rotor 1 and 2 is compressed and the pressure keeps increasing. When the pressure exceeds a certain value, the gas pushes the exhaust valve and is discharged from the exhaust pipe.

(5) the exhaust ends and is restored to the first process, only the I and 2 rotating plates exchange a position.

After the exhaust in accordance with the above process repeat. Thus each rotor plays two roles: to make the pump chamber from the air intake intake gas, compressed gas has been sucked in, so that it through the exhaust valve exhaust. When the rotor rotates once, the rotor 1 and 2 breathe in the primary gas and discharge the primary gas respectively. Therefore, when the rotor rotates once, two inspirations and two exhausts are completed.

The vacuum degree of single-stage pump is worse than that of double-stage rotary vane vacuum pump. Partial pressure of residual gas is 5×10-1-1pa, and total pressure (the sum of partial pressure of residual gas and residual steam) is 5Pa.

Product display

Technical parameters

| Model | Pump speed(m3/h) | Motor Power(KW) | Inlet Diam (inch) | Rotary speed(rpm) | Oil Capacity(L) | G.W(kg) | NoisedB (A) | Dimensions(mm) | |

| 50HZ | 60HZ | ||||||||

| SV-010 | 10 | 12 | 0.37 (3ph)0.55 (1ph) | G1/2 | 1400 | 0.5 | 20 | 64 | 405*253*210 |

| SV-020 | 20 | 24 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 20 | 64 | 405*253*210 |

| SV-025 | 25 | 30 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 22 | 64 | 405*253*210 |

| SV-040 | 40 | 48 | 1.5 (3ph)2.2 (1ph) | G11/4 | 1400 | 1.0 | 50 | 67 | 660*300*270 |

| SV-063 | 63 | 75 | 2.2 | G11/4 | 1400 | 2.0 | 83 | 68 | 695*420*295 |

| SV-100 | 100 | 120 | 3.0 | G11/4 | 1400 | 2.0 | 87 | 72 | 735*420*295 |

| SV-160 | 160 | 192 | 4.0 | G2 | 1400 | 4.5 | 152 | 74 | 805*520*410 |

| SV-200 | 200 | 240 | 5.5 | G2 | 1400 | 4.5 | 159 | 76 | 825*520*410 |

| SV-250 | 250 | 300 | 7.5 | G2 | 1400 | 7.0 | 230 | 76 | 1000*550*410 |

| SV-300 | 300 | 360 | 7.5 | G2 | 1400 | 7.0 | 236 | 76 | 1200*550*410 |

| SV-630 | 630 | 750 | 15.0 | DN100 | 960 | 35 | 620 | 75 | 1630*1300*980 |

| SV-750 | 750 | 900 | 18.5 | DN100 | 1150 | 35 | 640 | 76 | 1630*1300*980 |

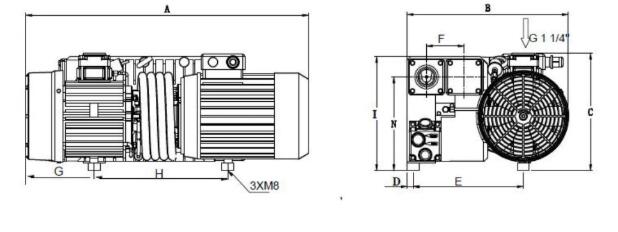

Installation dimensions

Related videos

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)