Steam Ejector Vacuum Pump in Vacuum Distillation Process of Cosmetics Plant Application

Under the social background of “beauty economy”, the cosmetics industry is growing rapidly and showing a trend of rapid differentiation. In the production of cosmetics, vacuum refining is often used to purify chemical components. Among them, vacuum distillation is a commonly used vacuum device, which is carried out under reduced pressure. It is generally used to separate substances that are easy to decompose when heated to boiling point under normal pressure, or with other distillation equipment Distillation methods, such as steam distillation, are combined to reduce distillation temperature and improve separation efficiency. Separation and purification of metal alkoxides, etc. Vacuum distillation is also used for deep purification of some special gases. Some compounds have high boiling points. In order to make such compounds boil, it is better to reduce the boiling pressure rather than increase the temperature. As soon as the pressure drops to the vapor pressure of the compound (at a certain temperature), the compound begins to boil and the distillation can proceed. This technology is called vacuum distillation and is commonly used in laboratories in the form of vacuum vaporizers. This technique is very useful for compounds whose boiling point exceeds their decomposition temperature at atmospheric pressure. Any attempt to boil such compounds at atmospheric pressure will cause them to decompose.

The basic principle of vacuum distillation is to use the difference of vapor pressure of each compound to achieve effective separation under high temperature and vacuum conditions. Vacuum distillation includes evaporation (or sublimation) and condensation. The separation effect mainly depends on their vapor pressure, which means the volatilization of substances. Each substance has its specific vapor pressure at a certain temperature.

EVP Vacuum pumps plays an irreplaceable role in vacuum distillation. In selection, vacuum pump can be selected reasonably according to the working pressure required by specific process and the nature of suction gas. Generally, the working pressure required by specific process is determined first. The vacuum degree required by negative pressure distillation, distillation, sublimation and other processes is high (low working pressure), negative pressure evaporation, drying, concentration and condensation Low vacuum degree (high working pressure) is required for crystallization, dehydration, decolorization, high temperature pump, chemical reaction absorption and vacuum conveying. After the working pressure is determined, the vacuum pump can be reasonably selected according to the size of the pumping volume and the nature of the pumping gas. Today, we analyze the application of steam jet pump in the vacuum distillation process of cosmetics factory: the requirements of EVP customers are as follows:

Quantity: Steam Ejector System

Operating pressure: 66Pa

Suction Flow: 2kg/hr water+ 5kg/hr Glycerol+ 1kg/hr Air + 10kg/hr Glycerol monocaprylate+ 5kg/hr Octanoic acid

System Volume : 2m3

Design Temperature : 136 Deg C

Motive steam using 10barg saturated steam

SPD (Short path distillatory) and Degasser working under different pressures

Shanghai EVP VACUUM Solution as follow:

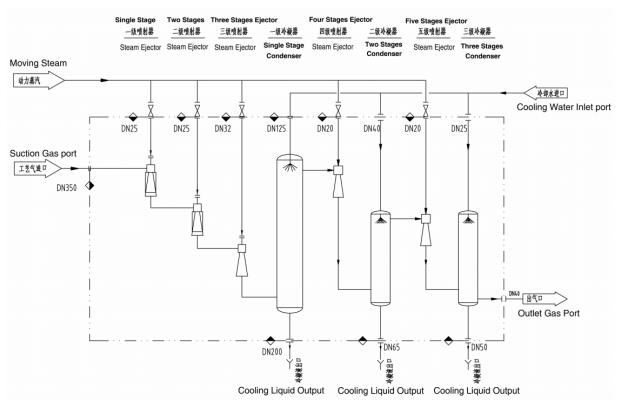

Five Stages Steam Ejector Vacuum Solution

Model: 5PSJ0.066-(2+21)/1.1

Suction Flow: 2kg/hr water+ 5kg/hr Glycerol+ 1kg/hr Air + 10kg/hr MAG+ 5kg/hr Octanoic acid

Operating pressure: 66Pa

Exhaust pressure: 1Atm 40 ℃

Exhaust flow: 18500m3 / h

Steam Ejector: FV / 0.2 MPa (g) / 200 ℃ / 5Stages

Condenser: FV/ 0.3 MPa (g) / 200 ℃ / 3Stages

Working steam consumption: 360kg / h

Cooling water consumption: 63m3 / h

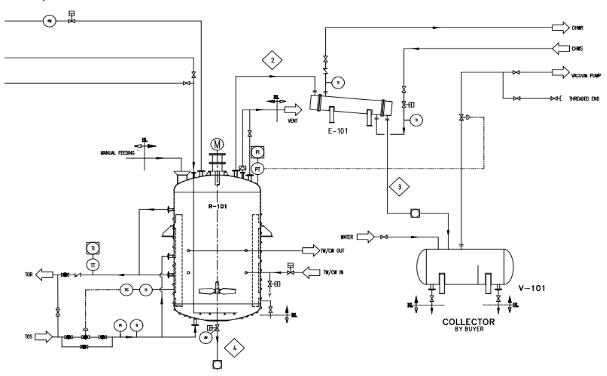

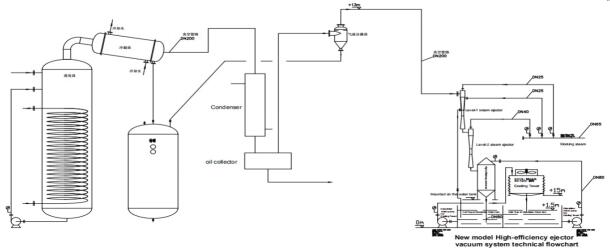

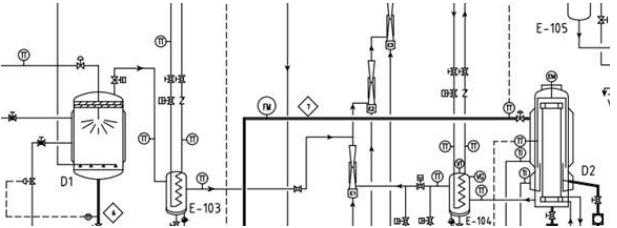

The simple PID Progress Drawing as follow:

In this Vacuum Distillation application, different requirement, different types vacuum pump is suitable, such as dry screw vacuum pump, water ring vacuum pump with Steam Ejector package, Roots pump with water ring vacuum pump package, roots pump with rotary piston vacuum pumps package, etc. If you need Vacuum Solution used to similar Vacuum Distillation as above, please contact EVP freely, we will provide most suitable vacuum pump solution.

Editor: Selena of SHANGHAI EVP VACUUM TECHNOLOGY CO., LTD

Key Words: steam ejector pump, vacuum distillation, vacuum pump in Cosmetics Plant

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)