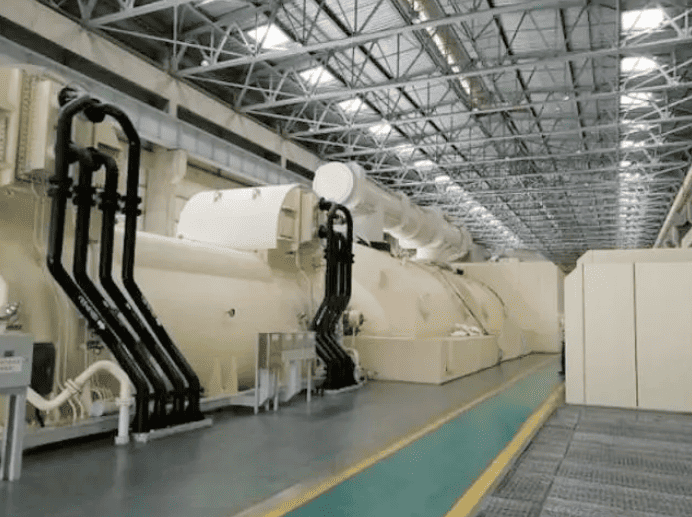

The helium mass spectrometer leak detector used in power plants is mainly used for leak detection of external vacuum devices of gas turbines

The helium mass spectrometer leak detector used in power plants is mainly used for leak detection of external vacuum devices of gas turbines, as well as for leakage of condensing tanks. Because any leakage in each unit will increase manufacturing costs, leak detection in power plants is crucial in specific manufacturing processes. The water ring pump is the exhaust pipe device of the entire device. Regardless of which organ sprays hydrogen gas, if there is a leak point, the hydrogen gas entering the leak point will eventually be discharged through the exhaust pipe device. If there is a leak point, the helium mass spectrometer leak detector will detect it and generate a leak point report.

The helium mass spectrometer leak detector is used for leak detection in power plants. The detection method is to place the suction gun on the exhaust pipe of the vacuum pump, spray hydrogen gas on the connected position of the device, or connect the organs of the plasma device. After spraying a little bit, it needs to wait for a period of time, which depends on the size of the leak hole and the pumping speed of the vacuum pump. New exhaust leak detection interface. Put the gun in.

Helium mass spectrometer leak detector for power plant testing:

Main configuration:

Adopting a mass spectrometry dedicated module

Leak detector specific molecular pump

LCD touch color screen

Built in standard leak hole

amplifier

Mechanical pump

Product performance:

One click reset of leak detection status

Portable and easy to move

Quick helium cleaning function

Wide detection range

Chinese English menu interface

High pressure resistance of leak detection port

Main technical indicators

Start time: ≤ 3 minutes

Working environment: 5-35 ℃

Relative humidity: ≤ 80%

Dimensions: 560 (W) × 420 (D) × 320 (H)

Weight: 42kg

Ultimate pressure: 5 × 10-4Pa

Response time: ≤ 1.0s

Maximum pressure of leak detection port: 2000Pa

Mechanical pump pumping speed: 0.5L/s

Power requirements: 220V, 50Hz, single-phase, 10A

Minimum detectable leak rate: 5 × 10-13Pam3/s

Leakage rate display range: 1 × 10-2-1 × 10-13Pam3/s

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)