Vacuum die casting system

What is vacuum die casting

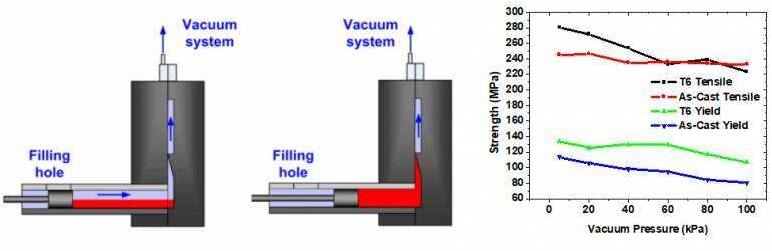

Vacuum die-casting is an advanced die-casting process which can eliminate or significantly reduce the porosity and dissolved gas in the die-casting die cavity during the die-casting process, so as to improve the mechanical properties and surface quality of the die-casting parts.

Die casting has been widely used in metal forming, but the negative effect of gas on the product seriously hinders the further development and promotion of the process. In the world, vacuum die-casting is a technology subject which is researched and developed by many countries. However, the most core technical index of vacuum die casting: exhaust cross-sectional area and continuous stability of the equipment have not been well solved.

What vacuum die casting system

Through the oil lubricated rotary vane vacuum pump (combined with roots vacuum pump), the gas in the die casting die cavity is removed during the die casting process, the vacuum degree in the die is reduced to 10 ~ 50mbara, and the porosity and dissolved gas in the die casting are eliminated or significantly reduced, so as to improve the mechanical properties and surface quality of the die casting.

vacuum system advantages:

1. Avoid the impact of power waste, heat, noise and environmental considerations on working conditions and personnel as much as the power cost and operating cost of the factory.

2. Heat accumulation: the heat generated by multiple independent machines in a limited space makes the working environment overloaded, thus affecting the air conditioning equipment.

3. Noise: the noise from all vacuum pumps and air compressors increases the noise level, causing excessive pressure and premature fatigue.

4. Production problem: peak demand for vacuum and compressed air requires additional machines. And these machines are more economical only when they are used occasionally, because the failure of one machine may cause the whole work line to be paralyzed.

5. High maintenance and power cost: not only does the maintenance of a series of single pump equipment consume too much time, but also the independent operation of compressor and vacuum pump increases the cost of power.

6. Keep the work site clean, tidy and beautiful.

7. The supply of vacuum source is stable without waste.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)