Vacuum pump application in the freeze drying industry

What is freeze dryer:

The freeze dryer is a machine consisting of a refrigeration system, a vacuum system, a heating system, and an electrical instrument control system. The frozen substance is first frozen into a solid state, and then the water therein is sublimated from a solid state into a gaseous state to remove the water and preserve the substance. Methods. The main components of the freeze dryer are divided into drying ovens, condensers, refrigeration units, vacuum pumps, heating/cooling devices, and the like.

In the process of drying compressed air, the freeze-drying is to precipitate the moisture in the compressed air by lowering the temperature of the compressed air. The working principle of the freeze dryer is the same as that of the refrigerator. After the compressed air passes through the frozen compressed air pipeline, the temperature of the compressed air drops to the required temperature to meet the drying requirements.

Vacuum freeze-drying technology has a wide range of applications in the fields of bioengineering, pharmaceutical industry, food industry, materials science and deep processing of agricultural and sideline products.

Vacuum pump application in the freeze drying industry:

The application characteristics of the vacuum system on freeze-drying mainly include the ability to pump steam, the vacuum limit of the freeze-drying box and the effective pumping speed at the outlet of the freeze-drying box.

Regardless of the type of drying, it is essential to remove moisture from the material. Vacuum freeze-drying removes moisture that is sublimed from the material at low temperature and low pressure. Therefore, the vacuum system of the vacuum freeze dryer must be able to remove water vapor, and according to the requirements of the freeze dryer process, the vacuum freeze degree of the medical freeze dryer should reach 1Pa, and the vacuum freeze degree of the food freeze dryer should be Reach 10Pa. The vacuum system must also have sufficient pumping speed and the ability to extract water vapor.

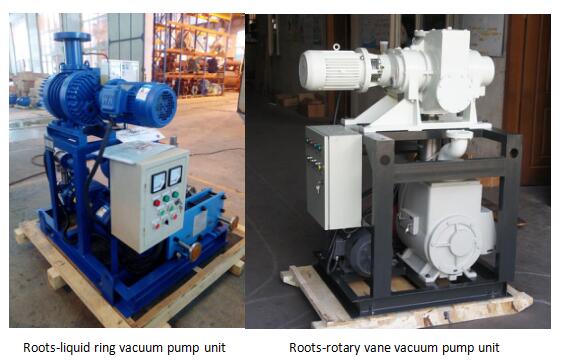

The vacuum pump of the vacuum system is preferably selected to remove part of the water vapor to prevent the performance of the vacuum freeze dryer from being deteriorated, and the water vapor enters the vacuum pump, causing the pump oil to be emulsified and the degree of vacuum to be lowered. For example, the Roots water ring pump unit or the Roots rotary vane pump and the slide valve pump unit require the rotary vane pump or the slide valve pump to be gas-filled. In order to shorten the pumping time, it is better to install a water ring pump directly connected to the freeze-drying chamber.

The vacuum systems currently used in freeze dryers are mainly divided into two categories, one is a vacuum pump that directly pumps steam; the other is a water trap plus a vacuum pump. The former has a simple structure and low cost, but it must be equipped with a steam boiler. There is still a phenomenon of returning water when the operation is inadvertent; the latter has a complicated structure and high cost, but the vacuum is high and the operation is reliable.

Keywords: vacuum freeze dryer, rotary vane vacuum pump, liquid ring vacuum pump, roots-liquid ring vacuum pump unit, roots-rotary vane vacuum pump unit

Edited by: Emily Fu (Shanghai EVP Vacuum Technology Co., Ltd.)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)