Vacuum Pumps in Beer Filling Machines

After cleaning, the empty bottle of beer bottle needs to pump the air/oxygen in the empty bottle before filling. First, the empty bottle is vacuumed, filled with CO2 gas, and then the CO2 in the bottle is pumped away, and later the beer is injected.

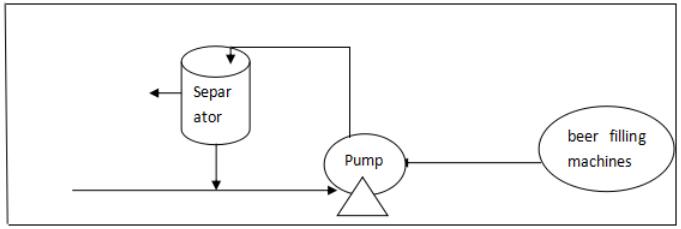

Flow chart:

Liquid ring vacuum pumps 2BV, 2BE series are recommended for this process.

Is the vacuum pump working fluid recycled?

The vacuum degree of the liquid ring vacuum pump is affected by two conditions of the working fluid, one is the working water temperature, and if the circulating water temperature is raised, the temperature will increase. If the cooling tower water is used in the beer industry, the water temperature will be affected by the climate, and the winter will be low in summer. If groundwater is used, the summer water temperature is very low; the other is the water quality. If recycled, some substances in the beer will affect the saturated vapor pressure of the water. Thereby affecting the vacuum degree of the vacuum pump.

Therefore, it is recommended that the working fluid should not be recycled.

How to optimize the vacuum system?

In the case that the working fluid can not fully realize the low-temperature pure water, the performance of the vacuum system can be improved as a whole, and a sealed Roots vacuum pump is added on the basis of the liquid ring vacuum pump to solve the vacuum under the influence of water quality and water temperature. Usually, when the liquid ring vacuum pump is pumped to 10~12kpa, the Roots pump will raise the vacuum to 6~8kpa.

Based on past experience, the following is a standard design, for reference only, please contact the Shanghai EVP professional team for specific selection:,

1)model:

20,000/hour line configuration EVP liquid ring vacuum pump: 2BV5-131, motor power: 11KW

24,000/hour line configuration EVP liquid ring vacuum pump: 2BV5-161, motor power: 15KW

40,000 / hour line configuration EVP liquid ring vacuum pump: 2BE1-202, motor power: 22KW

If you increase the Roots pump:

20,000 / hour line configuration Roots pump: 2BV5 131 + ZJP-300 motor power: 4KW

24,000/hour line configuration Roots pump: 2BV5 161+ZJP-300 motor power: 4KW

40,000 / hour line configuration Roots pump: 2BE1 202 + ZJP-600 motor power: 7.5KW

2), material: the impeller must be SS304, the rest can be cast iron or SS304

3), sealing: mechanical seal (single front end must increase the buffer tank and filter to avoid particles into the pump)

4), sealed flushing mode: external flushing (to avoid impurities with the washing fluid to destroy the seal and bushing)

5), with cavitation protection device

6) The diameter of the inlet pipe is the same as the standard diameter of the vacuum pump.

7) If the filling pump is required to run for a long time, configure the return pipe to avoid the vacuum pumping limit.

8) The vacuum degree of the vacuum pump inlet is absolutely reduced. Due to the difference of local atmospheric pressure, the same vacuum shows different values in different places. To standardize the application standard of the beer industry, it is recommended to increase the absolute pressure display at the vacuum pump inlet. Oil-filled shockproof and periodic correction of vacuum gauge to avoid errors caused by indication or instrument failure

9), pump and motor with coupling to avoid pump water into the motor

2BV Series Liquid Ring Vacuum Pump

| Curve No. | Model | Max. suction capacity | Ultimate vacuum mbar(MPa) |

Motor power kW |

Speed r.p.m |

Operating liquidflow rate L/min |

Noise dB(A) |

Weight kg |

|

| m3/min | m3/h | ||||||||

| 60V | 2BV2-060 | 0.45 | 27 | 33mbar (-0.097MPa) |

0.81 | 2840 | 2.5 | 62 | 37 |

| 61V | 2BV2-061 | 0.86 | 52 | 1.45 | 2840 | 2.5 | 65 | 41 | |

| 70V | 2BV2-070 | 1.33 | 80 | 2.35 | 2860 | 3 | 66 | 66 | |

| 71V | 2BV2-071 | 1.83 | 110 | 3.85 | 2880 | 4.7 | 72 | 85 | |

| 110V | 2BV5-110 | 2.75 | 165 | 4 | 1440 | 7.2 | 63 | 120 | |

| 111V | 2BV5-111 | 3.83 | 230 | 5.5 | 1440 | 8.8 | 68 | 150 | |

| 121V | 2BV5-121 | 4.66 | 280 | 7.5 | 1440 | 11 | 69 | 210 | |

| 131V | 2BV5-131 | 6.66 | 400 | 11 | 1460 | 16 | 73 | 280 | |

| 161V | 2BV5-161 | 8.33 | 500 | 15 | 970 | 22 | 74 | 390 | |

| 110V | 2BV6-110 | 2.75 | 165 | 4 | 1440 | 67 | 63 | 150 | |

| 111V | 2BV6-111 | 3.83 | 230 | 5.5 | 1440 | 10 | 68 | 200 | |

| 121V | 2BV6-121 | 4.66 | 280 | 7.5 | 1440 | 12 | 69 | 230 | |

| 131V | 2BV6-131 | 6.66 | 400 | 11 | 1460 | 17 | 73 | 315 | |

| 161V | 2BV6-161 | 8.33 | 500 | 15 | 970 | 23 | 74 | 426 | |

2BE1 Series Liquid Ring Vacuum Pump

| Model | Speed(Driving mode) | Shaft power | Motor power | Ultimatevacuum | Max. capacity | Weight (excl.motor) | |

| r/min | KW | 380V | hpa | M³/hr | M³/min | kg | |

| 2BE1-102 | 1450 (direct)1750 (V-belt) | 6.08.0 | Y132M-4-7.5Y160M-4-11 | 33hpa(-0.097MPa) | 246290 | 4.14.8 | 110 |

| 2BE1-103 | 1450 (direct)1750 (V-belt) | 8.211.1 | Y160M-4-11Y160L-4-15 | 33hpa(-0.097MPa) | 340412 | 5.76.9 | 125 |

| 2BE1-152 | 1450 (direct)1625 (V-belt)

1750 (V-belt) |

12.515.0

17.2 |

Y160L-4-15Y180M-4-18.5

Y180L-4-22 |

33hpa(-0.097MPa) | 450510

535 |

7.58.5

8.9 |

175 |

| 2BE1-153 | 1450 (direct)1100 (V-belt)

1300 (V-belt) 1620 (V-belt) 1750 (V-belt) |

16.310.6

13.4 19.6 22.3 |

Y180M-4-18.5Y160L-4-15

Y180M-4-18.5 Y180L-4-22 Y200L-4-30 |

33hpa(-0.097MPa) | 600445

535 648 700 |

10.07.4

8.9 10.8 11.7 |

200 |

| 2BE1-202 | 980 (direct)790 (V-belt)

880 (V-belt) 1100 (V-belt) 1170 (V-belt) 1300 (V-belt) |

18.213.4

16.3 23.8 25.7 30 |

Y200L2-6-22Y180M-4-18.5

Y180M-4-18.5 Y200L-4-30 Y200L-4-30 Y225S-4-37 |

33hpa(-0.097MPa) | 750590

670 860 888 950 |

12.59.8

11.2 14.3 14.8 15.8 |

460 |

| 2BE1-203 | 980 (direct)790 (V-belt)

880 (V-belt) 1100 (V-belt) 1170 (V-belt) 1300 (V-belt) |

29.521.2

24.8 34 38 42 |

Y250M-6-37Y200L-4-30

Y200L-4-30 Y225M-4-45 Y225M-4-45 Y250M-4-55 |

33hpa(-0.097MPa) | 1080870

980 1210 1320 1390 |

1814.5

16.3 20.2 22.0 23.2 |

530 |

| 2BE1-252 | 740 (direct)565 (V-belt)

660 (V-belt) 830 (V-belt) 885 (V-belt) 938 (V-belt) |

3823.7

31.8 45 54 60 |

Y280M-8-45Y200L-4-30

Y225S-4-37 Y250M-4-55 Y280S-4-75 Y280S-4-75 |

33hpa(-0.097MPa) | 17001200

1500 1770 2000 2100 |

28.320.0

25.0 29.5 33.3 35.0 |

870 |

| 2BE1-253 | 740 (direct)565 (V-belt)

660 (V-belt) 740 (V-belt) 792 (V-belt) 820 (V-belt) 880 (V-belt) 940 (V-belt) |

5437.2

45 50.8 60 68 75.1 88 |

Y315M-8-75Y225M-4-45

Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-75 Y280M-4-90 Y315S-4-110 |

33hpa(-0.097MPa) | 24501690

2100 2340 2560 2640 2780 3050 |

40.828.2

35 39 42.7 44 46.3 50.8 |

930 |

| 2BE1-303 | 740 (direct)590 (direct)

466 (V-belt) 530 (V-belt) 583 (V-belt) 660 (V-belt) 740 (V-belt) |

9865.5

48 58 64 79.8 96 |

Y315L2-8-110Y315L2-10-75

Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 |

33hpa(-0.097MPa) | 40003200

2520 2820 3100 3550 3840 |

66.753.3

42 47 51.7 59.2 64 |

1700 |

| 2BE1-305 | 740 (direct)590 (direct)

490 (V-belt) 530 (V-belt) 583 (V-belt) 660 (V-belt) 740 (V-belt) |

10870

55 61 68 90 110 |

Y355M1-8-132Y355M1-10-90

Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 Y315M-4-132 |

33hpa(-0.097MPa) | 45203750

3150 3380 3700 4090 4550 |

75.362.5

52.5 56.4 61.2 68.1 75.8 |

1820 |

| 2BE1-353 | 590 (direct)390 (V-belt)

425 (V-belt) 464 (V-belt) 530 (V-belt) 560 (V-belt) 620 (V-belt) 660 (V-belt) |

12163

72 85 95 110 133 152 |

Y355L2-10-160Y280S-4-75

Y280M-4-90 Y315S-4-110 Y315M-4-110 Y315L1-4-132 Y315L1-4-160 Y315L2-4-185 |

33hpa(-0.097MPa) | 53003580

3700 4100 4620 5000 5500 5850 |

88.359.7

61.7 68.3 77.0 83.3 91.7 97.5 |

2300 |

| 2BE1-355 | 590 (direct)390 (V-belt)

420 (V-belt) 464 (V-belt) 523 (V-belt) 590 (V-belt) 660 (V-belt) |

13675

80.8 95 113 136 182 |

Y355L2-10-160Y280M-4-90

Y280-4-90 Y315S-4-110 Y315M-4-132 Y315L1-4-160 Y315L2-4-200 |

33hpa(-0.097MPa) | 57004180

4260 4850 5230 6000 6510 |

9569.7

71 80.8 87.1 100 108 |

2450 |

| 2BE1-403 | 330 (V-belt)372 (V-belt)

420 (V-belt) 472 (V-belt) 530 (V-belt) |

98110

131 160 213 |

Y315M-4-132Y315M-4-132

Y315L1-4-160 Y315L2-4-200 Y355M2-4-250 |

33hpa(-0.097MPa) | 48605400 6470

7380 8100 |

8190

107.8 123.0 135.0 |

3750 |

| 2BE1-405 | 330 (V-belt)372 (V-belt)

420 (V-belt) 472 (V-belt) 530 (V-belt) |

100118

140 170 216 |

Y315M-4-132Y315L1-4-160

Y315L2-4-185 Y315L2-4-200 Y355M2-4-250 |

33hpa(-0.097MPa) | 60006700

7500 8350 9450 |

100.0111.7

125.0 139.2 157.5 |

3900 |

ZJP Roots Vacuum Pump

| Model | ZJP- 70 | ZJP- 150 | ZJP- 300 | ZJP- 600 | ZJP- 1200 | ZJP- 2500 | |

| Pumping speed(L/s) | 70 | 150 | 300 | 600 | 1200 | 2500 | |

| Ultimate pressure (Pa) |

5×10-2 (1stage piston pump as backing pump) | ||||||

| 1×10-1 (2 stage piston pump as backing pump) | |||||||

| Diff. pressure at overflow valve (Pa) | 4×103 | 2. 7×103 | |||||

| Motor rotary speed(RPM) | 3000 | ||||||

| Suitable motor power(kW) | 1.1 | 2.2 | 4 | 7.5 | 11 | 22 | |

| Flange size | inlet(mm) | 80 | 100 | 150 | 200 | 250 | 320 |

| outlet(mm) | 80 | 100 | 150 | 200 | 200 | 320 | |

| Cooling water consumption(L/h) | 120 | 150 | 200 | ||||

| Allowable temperature(℃) | 100 | ||||||

| Vacuum pump oil | 100# | ||||||

| Weight(without motor)(kg) | 110 | 205 | 265 | 780 | 880 | 1350 | |

Key words: 2BV liquid ring vacuum pump, 2BE liquid ring vacuum pump, roots vacuum pump

Edited by: Emily FU / Shanghai EVP Vacuum Technology Co., Ltd.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)