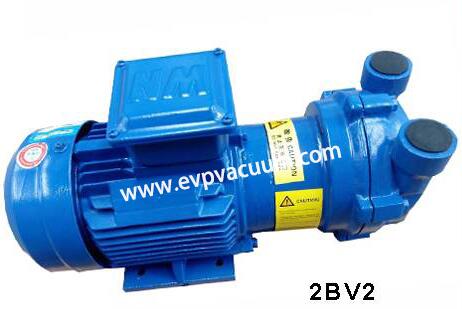

Vacuum pump for chocolate production

Dark chocolate, milk chocolate and white chocolate

In the process of delivering products such as jam, sugar solution, dark chocolate, milk chocolate, or white chocolate that contain nuts or other ingredients, my mother can offer a variety of solutions.

As one of the leading manufacturers of chocolate vacuum pumps, we have a number of vacuum pumping solutions to meet the needs of the chocolate industry.

Products, applied knowledge, understanding of customer value, interrelationships, and product needs are our guiding lights when choosing the best solution for our customers.

Vacuum pump is designed to transport high viscosity medium, such as liquid cocoa paste, cocoa, cocoa butter, chocolate, sugar solution, caramel and other sugar products. The front and rear of the pump are provided with heating jacket. Special clearances are provided for the rotor, idler wheel and idler shaft sleeve for working pressure up to 12 bar.

Half a century of chocolate vacuum pump industry application experience and work closely with top manufacturers, achievement quality super chocolate pump, it can meet the strict requirements in the process of chocolate manufacturing.

Let’s take a look at the problems we have with vacuum pumps. Right?

Vacuum pump overload and low efficiency

One, when using vacuum pumps, these problems often lead to motor overload operation. Combined with the installation form and working principle of vacuum pump, the causes of overload and low efficiency of vacuum pump are analyzed.

(1) the impact of basic installation on the equipment itself.

The installation quality of equipment base has a great influence on the operation quality of equipment. Improper placement of the pad can easily cause the anchor bolts of all parts of the equipment to hang in the air. During the calibration and fastening process, tightening the anchor bolts will cause deformation of the slideway of the crosshead in the crankcase, and the crosshead will be blocked during the reciprocating operation of the slideway, resulting in increased load.

The structural design of the piston vacuum pump is that the cylinder block is at one end of the cylinder block. The weight of the cylinder block is heavier after adding the piston and the inlet and outlet air valve. If the lower bracket or the upper hanger is not considered in the basic design, the cylinder will be suspended. The dead weight of the cylinder block will lead to the deformation of the crankcase slideway and the difference in the concentricity between the cylinder block and the slideway, which will cause the crossheave to be blocked in the reciprocating movement of the slideway, and the piston to be blocked in the reciprocating movement of the cylinder, resulting in increased load.

According to the above analysis, it was found that the end of the vacuum pump cylinder was slightly lower than the end of the crankcase, and the gasket at the end of the cylinder was less than the normal value. After the anchor bolt is tightened, the crosshead deforms, causing the crosshead to get stuck in the slideway and the piston to move back and forth in the cylinder, resulting in increased load. This is one of the reasons why the motor overheats.

(2) coke of cylinder block and valve

Affected by the process, reciprocating pump cylinder and valve body easy to coke. The coking of the cylinder and the piston will cause the piston to be blocked as it reciprocates in the cylinder and increase the load. Coking of valve body can lead to poor exhaust, loose valve closing, increased load and low vacuum. Focusing at the cylinder clearance can also cause the piston to collide with the cylinder and increase the load. It was found that the cylinder block and disc were coking, which was the main reason for the low vacuum.

2. Compared with the above common problems, the corresponding solutions are as follows:

1. If the pump temperature of dongguan vacuum pump is too high, it should be operated according to the instruction first, but it cannot be operated correctly. After – sales service or by professional maintenance application.

2. For article 2, repair worn parts. If the damaged part is serious, replace it directly.

3. Reassemble.