Vacuum pump for extruder

Extruder vacuum pump introduction

1.There are many water ring vacuum pumps. If the impurities need to match the water ring vacuum pump, you can check the above table by yourself.

2. Water ring vacuum pump adopts direct connection design with compact appearance.

3. Wear resistance, corrosion resistance, high temperature resistance, long service life.

4. Complete models, available from stock, professional supporting facilities.

5. Very energy saving and low noise

6.Any gas can be extracted, just water vapor.

2bV series vacuum pump is an upgraded product developed by EVP vacuum co., LTD on the basis of the traditional water ring vacuum pump with the latest technology. Mechanical coaxial direct connection design, high reliability, easy installation and maintenance, volume 30% smaller than the traditional vacuum pump. Stable operation, noise less than 62 db, with self – suction ability, easy to operate. With an oil-free design, maintenance is largely unnecessary. 50% of the working fluid of the gas-water separator distributed by the pump can be recycled, which reduces pollution and operating costs. Bronze impeller is used to improve the corrosion resistance of the pump.

According to the customer’s requirements, using stainless steel material, the pump will operate normally in harsh environment. 2BV series water ring vacuum pump is a single stage coaxial pump with integrated structure. Shaft seal adopts mechanical seal, simple structure, simple installation, no oil, safe and reliable.

usage

2BV series water ring pumps are widely used in machinery, petrochemical, pharmaceutical, food and sugar industries. Because in the working process, the compression process is isothermal gas, so the compression and suction of explosive gas, less harm, wide range.

Scope of application:

It is mainly used to pump no solid particles, insoluble in water and corrosive gas. Through the role of water ring, negative pressure is generated in the air pump sealing system, playing the functions of vacuum filtration, vacuum drying, vacuum dehydration, vacuum pumping and so on.

The impeller made of bronze is superior to other vacuum pumps. If it is to be used for inhalation of corrosive gases, vapors or liquids, it must be of the appropriate low attenuation material, which can be explained at the time of ordering.

Working principles:

As shown on the right, a certain amount of water is injected into the pump chamber before starting. The impeller 4 is mounted eccentrically in the circular pump body. With the rotation of the impeller, the working liquid forms a moving liquid ring in the pump body, and the inner surface of the liquid ring is eccentric with the impeller. Because the suction and discharge ports are located in the proper position of pump cover 1, the liquid ring pump can complete the mutual continuity of suction, compression and discharge. The process of breathing in mourning.

At the same time, as part of the liquid exhaust process with the loss of air flow, so during the operation of the pump must be continuous water supply, to ensure the normal and stable operation of the pump.

Product display

Product specifications

| Curve No. | Model | Max. suction capacity | Ultimate vacuum mbar(MPa) |

Motor power kW |

Speed r.p.m |

Operating liquidflow rate L/min |

Noise dB(A) |

Weight kg |

|

| m3/min | m3/h | ||||||||

| 60V | 2BV2-060 | 0.45 | 27 | 33mbar (-0.097MPa) |

0.81 | 2840 | 2.5 | 62 | 37 |

| 61V | 2BV2-061 | 0.86 | 52 | 1.45 | 2840 | 2.5 | 65 | 41 | |

| 70V | 2BV2-070 | 1.33 | 80 | 2.35 | 2860 | 3 | 66 | 66 | |

| 71V | 2BV2-071 | 1.83 | 110 | 3.85 | 2880 | 4.7 | 72 | 85 | |

| 110V | 2BV5-110 | 2.75 | 165 | 4 | 1440 | 7.2 | 63 | 120 | |

| 111V | 2BV5-111 | 3.83 | 230 | 5.5 | 1440 | 8.8 | 68 | 150 | |

| 121V | 2BV5-121 | 4.66 | 280 | 7.5 | 1440 | 11 | 69 | 210 | |

| 131V | 2BV5-131 | 6.66 | 400 | 11 | 1460 | 16 | 73 | 280 | |

| 161V | 2BV5-161 | 8.33 | 500 | 15 | 970 | 22 | 74 | 390 | |

| 110V | 2BV6-110 | 2.75 | 165 | 4 | 1440 | 67 | 63 | 150 | |

| 111V | 2BV6-111 | 3.83 | 230 | 5.5 | 1440 | 10 | 68 | 200 | |

| 121V | 2BV6-121 | 4.66 | 280 | 7.5 | 1440 | 12 | 69 | 230 | |

| 131V | 2BV6-131 | 6.66 | 400 | 11 | 1460 | 17 | 73 | 315 | |

| 161V | 2BV6-161 | 8.33 | 500 | 15 | 970 | 23 | 74 | 426 | |

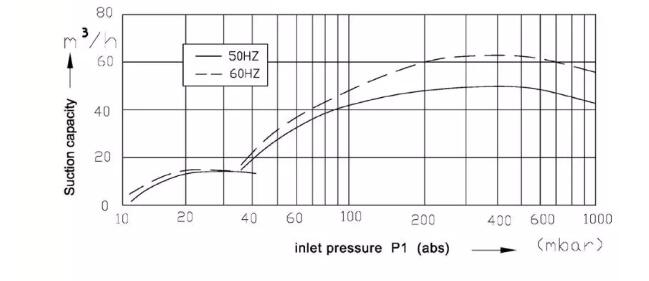

Performance curve

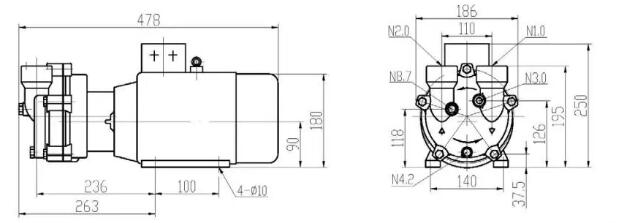

Installation size