Vacuum pump for toxic gas

Toxic gas, as the name implies, is a gas that is harmful to human body and can cause human poisoning.

Definition of toxic gas:

The common toxic gases are carbon monoxide, sulfur dioxide, chlorine, phosgene, double phosgene, hydrogen cyanide, mustard gas, Lewis gas, VX, sarin, BZ, tabun, soman, etc. There are three kinds of toxic gases: nerve paralysis gas, respiratory paralysis gas and muscle paralysis gas.

Toxic gas classification:

1. Irritant gas refers to the gas that has an irritant effect on the mucous membrane of eyes and respiratory tract. It is a toxic gas often encountered in the chemical industry. There are many kinds of irritant gases, the most common are chlorine, ammonia, nitrogen oxide, phosgene, hydrogen fluoride, sulfur dioxide, sulfur trioxide and dimethyl sulfate.

2. Asphyxiating gas refers to the toxic gas asphyxiating gas that can cause hypoxia of the body, which can be divided into simple asphyxiating gas, blood asphyxiating gas and cell asphyxiating gas. Such as nitrogen, methane, ethane, ethylene, carbon monoxide, nitrobenzene vapor, hydrogen cyanide, hydrogen sulfide, etc.

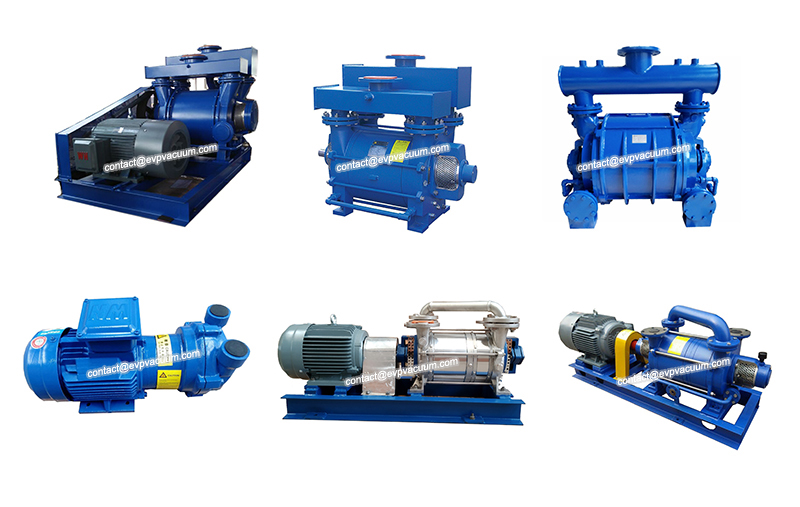

Due to the outstanding advantages of isothermal compression of water ring vacuum pump, the vacuum suction of toxic gas is particularly suitable for pumping or pumping, flammable and explosive gases, and because of the water seal, it can inhale and pump toxic and harmful gases. Avoid and reduce hazards as much as possible. I believe most users know that the material to be vacuumed can be solid, liquid or gas. Vacuum suction of new sand, old sand, dry soil powder, coal powder and some powder materials (such as zinc oxide powder) are typical examples of vacuum suction. Next, EVP vacuum pump manufacturing will introduce vacuum suction solid, vacuum suction liquid and vacuum suction gas.

Both vacuum suction conveying and positive pressure conveying use the pressure difference to push the material for conveying. The vacuum pump or blower used for vacuum suction changes the internal part of the system into a vacuum state, forming a pressure difference with the external atmospheric pressure, making the material move in the pipeline in a suspended state, and finally separating the material. Material and gas flow through the separator.

Yes, vacuum pumping can be done by using a vacuum pump or by using a blower. In general, the vacuum degree during vacuum suction reaches 30 to 50 kPa, i.e. vacuum pump, and only 80 to 90 kPa vacuum is required during suction, which can be achieved by using blower. In other words, using a vacuum pump is a high vacuum suction, while using a blower for vacuum suction is a low vacuum suction. One thing to understand is that the higher the vacuum is, the thinner the air is, and the corresponding material carrying capacity will be reduced during transportation.

In the application of vacuum pump in vacuum suction, some problems need to be noted:

1. Vacuum suction solids

The materials being sucked and delivered generally include sand, salt, iron filings, fire-resistant mud, clay powder, etc. Therefore, it is very important to choose the air velocity of vacuum pump reasonably. Too small, less than the settlement speed of the material, the material can not be attracted for transportation, or the transportation will be blocked; too small, not only the power consumption will increase, but also the wear of the equipment such as the conveying pipe will be accelerated.

2、 Vacuum suction and delivery of liquid

This is divided into two ways: direct suction and brief suction.

Direct suction: vacuum pump directly suction liquid, and then discharge to the required place. This is the problem of directly pumping liquid by vacuum pump. It is necessary to consider whether the pumped liquid is corrosive to the vacuum pump, whether it is toxic, flammable, explosive, etc., otherwise, relevant measures shall be taken.

Indirect suction: that is to say, the suction method of pumping gas from an intermediate container to form a certain vacuum degree, and then sucking the liquid into the container. In order to prevent the pumped liquid from being pumped into the vacuum pump by mistake, one or more buffer tanks shall be set between the container and the pump. The liquid is dense and separated in the tank.

3. Vacuum suction gas

This is the most basic application of vacuum pump, the difference is that its purpose is not to make a container form a vacuum, but to draw in the gas through the formed vacuum, and then send it out.