Vacuum pump for door panel extruder

The extruder used in PVC wide door panel production line adopts SCR DC or frequency converter for speed regulation and joint venture temperature control instrument, which has the advantages of speed regulation, high temperature control accuracy and convenient operation. The auxiliary machine is composed of vacuum setting table, traction machine, cutting machine and pushing frame. Equipped with large-scale forced cooling device to ensure door plate finalization. The crawler type traction machine adopts the speed control of decelerating motor and frequency converter. The utility model has the advantages of reasonable structure, large traction force, stable traction, etc. The cutting machine has the advantages of accurate operation and high cutting accuracy. The pusher frame is attached with a movable pusher car and rubber protective layer, which is easy to use. The auxiliary unit adopts programmable computer control or domestic control system, and the whole unit is stable.

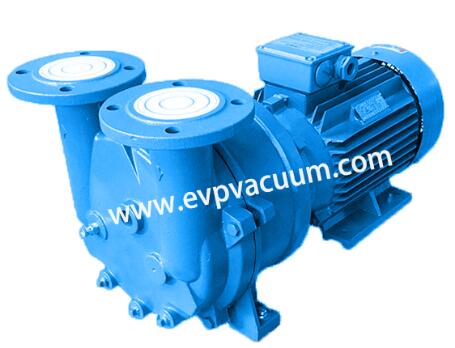

Special water ring pump for door frame attached extruder, water ring pump manufacturer, special vacuum pump for pipe extruder

Correctly install the vacuum lines on the vacuum pump and vacuum extruder

Vacuum pipeline is an important part of vacuum pump extruder, which mainly includes air filter (such as air, oil, water separator) installed in the intake pipeline of vacuum pump, muffler and vacuum meter installed in the exhaust port of vacuum pump. Guangyi water pump thinks that the proper selection of vacuum pipeline is conducive to the normal operation of the vacuum extruder, and it is easy to obtain high-quality bricks and tiles. Generally, the longer the vacuum line is, the greater the resistance along the path and the local resistance is, so the vacuum degree obtained by the vacuum extruder is unlikely to be very high.

Therefore, the length of the vacuum pipeline should be shortened as much as possible. It is better to install the vacuum pump near the vacuum extruder or in the vacuum extruder (only limited to small vacuum pump), in order not to affect the operation, use and maintenance of the vacuum pump and the vacuum extruder.

The diameter of the vacuum pipeline should be selected according to the regulations of the imported vacuum pump, and the curved pipeline, elbow and three parts should be used as little as possible At the same time, the pipe joint with reliable sealing and convenient connection shall be adopted.

Only in this way, can we ensure the high vacuum degree of the vacuum extruder. It should be noted that unlike chemical and food factories, brick factories extract air from the mud, which contains more dust particles. If not removed, the relevant parts of the pump will be seriously worn. As for the vacuum pump with oil as working medium, because of the closed-circuit circulation, the dust deposited continuously will abrade the parts and make the oil gradually thickened, flow difficult, reduce the pumping capacity, and block the machine.

Therefore, “air filter” shall be installed on the air extraction pipeline to intercept the dust in the air flow and prevent it from entering the vacuum pump. The filter should not only have small resistance and good filtering effect, but also be simple in structure, convenient in installation, disassembly and cleaning, small in volume, and larger than the pumping capacity of the vacuum pump, so as not to form a “bottleneck” and affect the pumping efficiency of the pump. Because the resistance of the gas flowing in the pipeline is directly proportional to the length of the pipeline and inversely proportional to the cross-sectional area of the pipeline, the diameter of the extraction and exhaust pipe must not be smaller than the hole diameter of the air inlet and exhaust port on the equipment on the premise of convenient operation and maintenance. The shorter the pipeline, the straighter the pipe and the fewer the joints, the better. The whole system should be unblocked without leakage to ensure the extraction rate.