Vacuum pump for vacuum sucker

Vacuum sucker working principle?

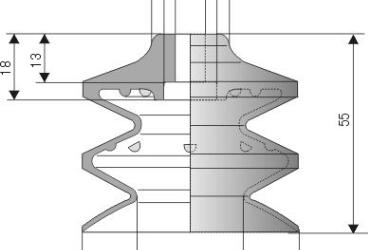

The working principle of the flat vacuum sucker is shown in the figure. Firstly, the vacuum suction cup is connected with the vacuum equipment (such as vacuum generator, not shown in the figure) through the nozzle, and then contacts with the object to be lifted, such as glass, paper, etc., to start suction of the vacuum equipment, so that negative pressure can be generated in the suction cup, so that the object to be lifted can be firmly sucked, and then the lifting object can be moved.

When the lifting object is moved to the destination, it is inflated smoothly into the vacuum suction cup, so that the vacuum suction cup changes from negative pressure to zero pressure or slightly positive pressure, and the vacuum suction cup is separated from the lifting object, thus completing the task of lifting and transporting heavy objects.

Vacuum sucker is one of the actuators of vacuum equipment. The material of sucker is made of NBR, which has great breaking force. Therefore, it is widely used in various vacuum sucker equipment, such as construction, paper industry, printing, glass and other industries, to realize the task of sucking and transporting thin and light articles such as glass and paper.

Extended information:

Characteristics of vacuum sucker

1. Vulnerability to wear and tear. Because it is usually made of rubber and directly touches objects, it wears badly, so it wears quickly. It is a pneumatic fragile part.

It is for this reason that it is so prominently highlighted from many pneumatic components.

2. Easy to use. No matter what material the object is sucked into, it can be used as long as it can be sealed and air-tight. Electromagnetic chuck can not be used, it can only be used in steel, other materials of plate or object can not be absorbed.

3. No pollution. Vacuum suction cups are particularly environmentally friendly, and do not pollute the environment. There is no light, heat, electromagnetic and other generated.

Fourth, do not hurt the workpiece. Vacuum sucker is made of rubber material, so it will not cause any damage to the workpiece if the workpiece is sucked or put down. However, hook-type and cable-type hangers are not feasible. In some industries, the surface requirements of workpieces are particularly stringent, they can only use vacuum suckers.

Which Vacuum Pump to Use for Vacuum Sucker

One of the key accessories of vacuum sucker manipulator equipment is vacuum pump for vacuum sucker. Vacuum pump for vacuum sucker has higher vacuum degree, so it is widely used in various vacuum sucker equipment, such as construction, paper industry, printing, glass and other industries, in order to realize the task of replacing manual transport of thin and light articles such as glass and paper.

General rotary vane vacuum pump is used in vacuum sucker because vacuum sucker is connected with atmospheric pressure, so there will be a phenomenon of vacuum pump stuck and damaged by fuel injection and smoke. Vacuum degree of water ring vacuum pump is lower than that of rotary vane vacuum pump, and need to be connected with circulating water cooling cycle, which kind of vacuum pump is used for vacuum sucker? What about vacuum pumps? SV vacuum pump for vacuum suction cup has a good effect. It is not afraid to suck the atmosphere, will not have the trouble of fuel injection and smoking, and has a high vacuum. It is the most suitable vacuum pump product for vacuum suction cup.

SV vacuum pump