Vacuum pump for vacuum vulcanization

Vacuum vulcanization molding

Vacuum plate vulcanizing machine is used for vulcanizing process of rubber and plastic products by vacuum molding. The rubber material flows in the vacuum state fills the mold cavity and completes the molding vulcanization under the heating, the pressurization. There is no oxidized surface layer at the mark of glue flow, good melting, no bubble inside the finished product, no defect in appearance, and the product quality is improved.

Moulded degassing

Challenges in the application of vacuum plate vulcanizer:

Vacuum pump temperature management

The polymerization is accelerated by too high a temperature

Condensation may occur if the temperature is too low

Vacuum pump temperature management

Vacuum vulcanization special rotary vane vacuum pump

Suitable temperature, very suitable for this application, amboyuan suggested setting vacuum buffer tank to reduce the gas temperature, amboyuan suggested setting activated carbon adsorption trap to collect resin steam on the gas path.

Rotary vane vacuum pump scope of application:

1. Rotary vane vacuum pump is suitable for vacuum pumping in airtight system. Such as vacuum packaging, vacuum forming, vacuum suction.

2. Inlet pressure range: 100Pa~ 100,000pa, oil mist will be generated at the exhaust port of vacuum pump working beyond this range. XD type rotary vane vacuum pump working environment temperature and suction gas temperature should be between 5 ℃ and 40 ℃.

3, rotary vane vacuum pump can not remove water or other liquids. Do not remove explosive, flammable, high oxygen content, corrosive gas.

Product features:

1. High ultimate vacuum, less than 0.5 millibar

2. High pumping speed

3. Compact structure, small size, light weight, especially suitable for supporting the machine

4. Reliable oil separation and oil circulation system, low working noise, can be less than 67 db, exhaust clean

5. Capable of extracting water gas and some condensable gas

6. Easy installation and maintenance, low cost and interchangeable with foreign products

7. Imported raw materials are used for key parts to ensure the overall service life

8. Equipped with oil return prevention device, no oil return

9. Environment-friendly, the pump is equipped with oil mist eliminator, which can remove 99.999% of the oil in the exhaust gas

10. Compact structure, scientific and reasonable design, lightweight, easy to install in industrial systems

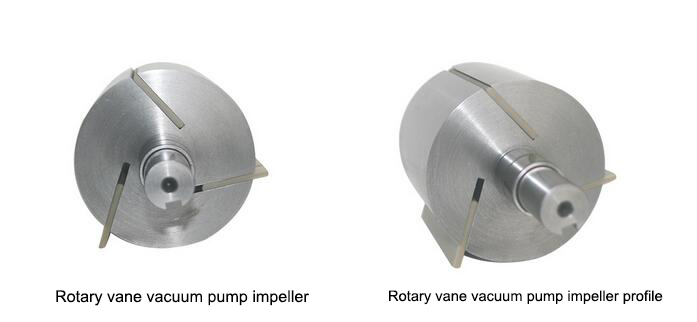

Photographs of products

Product Feature Map (Main Components)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)