vacuum pump formula for calculating pumping velocity

Vacuum elements with the same vacuum degree can share a gas-water separator. In the front section of the forming part with a very small gas-water volume ratio, one gas-water separator can be used for more vacuum elements. In the back section of the forming part and the pressing part with large gas-water volume, a gas-water separator should not be used for too many vacuum elements. Centrifugal fan or Roots fan should be selected as the vacuum generator for the vacuum components with low vacuum (5-15kPa) in the initial stage of forming zone. For other vacuum components, Roots vacuum pump or water ring vacuum pump are selected according to the vacuum requirement.

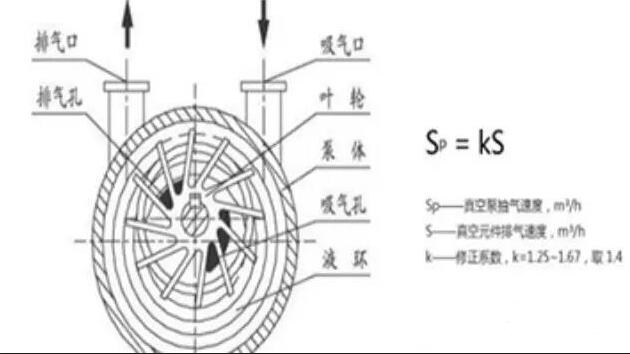

Roots vacuum pump mechanical exhaust and noise, due to the existence of mechanical wear and tear, resulting in heavy maintenance workload, but do not need working fluid, the system is simple. Water ring vacuum pump has less maintenance workload, less power consumption than the former, and large single-machine capability, but it needs working fluid, and the system is relatively complex. Water-ring vacuum pumps are often used in the vacuum system of large paper machines, which refer to water-ring vacuum pumps.

When choosing water ring vacuum pump, one pump with baffle and two chambers can be selected. The two chambers correspond to the vacuum components required by different vacuum degrees and work under different vacuum degrees. Reducing the number of vacuum pumps can not only save equipment investment, but also reduce the total installed capacity of motor, thus reducing energy consumption and system operation costs. At the same time, it will reduce the area occupied and save capital investment.

The pumping speed of the vacuum pump is determined by the exhaust speed of the vacuum element, the vacuum degree, the average pressure in the pipeline, the diameter of the pipeline and the length of the pipeline. Considering reasonable pipe diameter and economical pipe pressure drop, the pumping speed of vacuum pump is calculated according to the following formula.

Sp = kS

Type: Sp – Vacuum Pump Pumping Speed, m/h

S-exhaust velocity of vacuum element, m/h

K – Correction coefficient, k = 1.25 ~ 1.67, take 1.4.

The type of vacuum pump can be determined according to the required pumping speed Sp and the vacuum requirement of the vacuum element. When arranging vacuum pumps, they should be located as close as possible to the vacuum elements, so as to shorten the length of the vacuum pipeline and reduce the energy consumption of the system.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)