vacuum pump in transformer industry of application description

Guidelines for the use of vacuum pumps or vacuum units during transformer vacuuming process

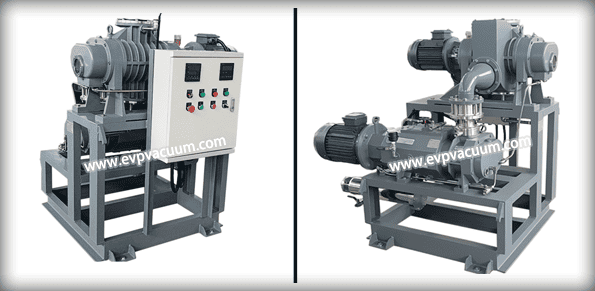

Vacuuming is an important step in the installation and maintenance of transformers. The use of vacuum pumps or vacuum units is particularly important in this process. The following will provide a detailed explanation on how to correctly use these devices when vacuuming transformers.

Preliminary preparation

Before using a vacuum pump or vacuum unit, it is necessary to ensure that the sealing performance of the transformer is good to avoid air leakage that affects the vacuum effect. At the same time, check the operating status of the vacuum pump or unit to ensure that it is working properly and the oil level is sufficient.

Operation steps

1. Connecting equipment: Connect the vacuum pump or unit to the transformer, ensuring that the connection is tightly sealed.

2. Turn on the equipment: Follow the equipment operation manual to start the vacuum pump or unit and begin the vacuuming operation.

3. Monitoring vacuum degree: During the vacuum pumping process, the vacuum degree of the transformer should be monitored in real time to ensure that it meets the preset standards.

4. Turn off the equipment: When the vacuum degree reaches the required level, turn off the vacuum pump or unit and disconnect it from the transformer.

Precautions

1. Safe operation: During the operation process, it is necessary to comply with safety regulations to avoid accidents.

2. Regular inspection: Regularly inspect and maintain the vacuum pump or unit to ensure its stable and reliable performance.

3. Record data: During the vacuuming process, record relevant data in detail for subsequent analysis and improvement.

By following the above steps and precautions, it is possible to ensure the effective use of vacuum pumps or vacuum units during the transformer vacuum pumping process, thereby improving the operational efficiency and safety of the transformer. At the same time, correct operating methods can also help extend the service life of equipment and reduce maintenance costs.

What industries use transformers?

1. Power Industry

The power industry is the main application area of transformers, which are widely used in power transmission and distribution systems. Transformers are able to transmit high-voltage electricity to long distances and reduce its voltage to make it suitable for subsequent distribution and use. In addition, transformers can also be used for grid protection and control, as well as power conversion and parameters that change power quality.

2. Petrochemical Industry

The petrochemical industry requires a lot of electricity to run its production lines and equipment. In this process, large transformers are used to reduce high-voltage electricity to a voltage level suitable for use in the factory. In addition, transformers can protect power equipment from damage caused by power fluctuations and power instability.

3. Manufacturing Industry

The manufacturing industry also requires a lot of electricity to drive its production chain. Transformers are used to change the voltage, frequency and shape of electricity to meet specific manufacturing needs, such as electric welding, electric cutting, etc. In addition, transformers are also used in metal processing, mining and rail transportation industries, etc.

4. Construction Industry

The construction industry requires electricity to meet the basic power needs of buildings, including ventilation, lighting and air conditioning. Transformers are widely used in these scenarios to provide appropriate voltage levels to serve different application equipment in buildings.

5. Transportation Industry

Transformers are also used in the transportation industry, including high-speed rail, railways, subways, airports, etc. They are used to drive motors, power supply for infrastructure such as trains and road traffic lights.

In summary, transformers play a vital role from the power industry to the manufacturing industry, construction industry and transportation industry. In different industries, transformers are used in different scenarios and needs, and their role that cannot be ignored has profoundly affected our lives and work.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)