vacuum pump in vacuum cooling

Vacuum cooling:

Vacuum cooling is mainly used for cold treatment of food, fruits and vegetables and cut flowers. Vacuum cooling is to vacuum the fruits and vegetables in the vacuum chamber into the insulated vacuum chamber. When the corresponding water vapor, fruits and vegetables with water saturation pressure on the gap surface of fruits and plant fibers start to evaporate in vacuum at room temperature, the evaporation will evaporate the far end latent heat, which will reduce the temperature of fruits and vegetables, and further reduce the temperature of vegetables to the required temperature. Water boils at 100 ℃ at atmospheric pressure. However, the pressure drop and boiling point are also reduced, which can reduce the boiling point of water available for this phenomenon, but in order to evaporate water, heat must be absorbed.

vacuum cooling principle:

The principle of vacuum cooling is similar to vacuum drying, in which water evaporates rapidly under vacuum. The difference is that vacuum drying is to remove water, and vacuum cooling is only to remove heat by evaporating water to achieve cooling and cooling. The professional vacuum pump supplier tells you some knowledge that water evaporates at 100 ° C under normal pressure, and the evaporation heat is 2256kj / kg. When the pressure drops to 610pa, the water will boil at 0 ° C (at this time, it is also the three-phase point of water, and the evaporation heat is 2500kj / kg. In other words, in the state of low-pressure vacuum, the evaporation of water will take away more heat, so as to achieve the refrigeration effect.

In daily life, water boils at 100 ° C at a atmospheric pressure (101-325 PA). However, the boiling temperature of water is not constant and decreases (or increases) as the pressure decreases (or increases). For example, the boiling point of water is 76 ℃, the temperature is 40 196.6 PA, 29 ℃, 4 kPa, 14 ℃, 1.6 kPa. Lower the boiling point to make the water evaporate easily. Because steam water molecules have higher energy than liquid water molecules, water must absorb the latent heat of evaporation when evaporation, and its latent heat of evaporation increases with the decrease of boiling point. According to the principle, the object to be treated can be placed in a closed vacuum box, which can bear a certain negative pressure and be pumped by a suitable vacuum system. With the increase of vacuum degree in the vacuum tank, the boiling temperature of water decreases. It is easy to evaporate, when water evaporates, it can only absorb the heat of the object itself, and can quickly cool the object to be processed.

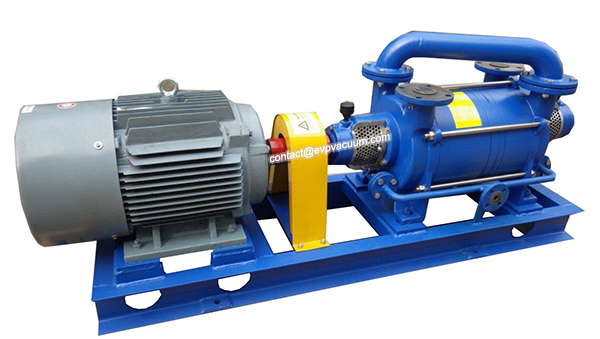

The core equipment of vacuum cooling is vacuum chamber and imported vacuum pump. After the product enters the vacuum chamber, the main process begins to pump air. Pump the pressure in the vacuum chamber to the corresponding saturated steam pressure and maintain it. The water in the product starts to evaporate and take away. Heating, at which point the temperature of the product will drop rapidly until the temperature of the product cools to the required temperature (for some vacuum pumps, condensation equipment may be required to capture water vapor).

Compared with air cooling, water cooling and other cooling methods, vacuum cooling has the advantages of energy saving, fast cooling speed, relatively uniform cooling and little impact on product structure. It also has the problems of large investment and high weight loss rate. But on the whole, it is also a fast and safe cooling technology, which transcends the shortcomings and can obtain high-quality products.

Because vacuum is everywhere, EVP vacuum pump manufacturers analyze the application of vacuum pump in vacuum cooling. Compared with traditional heat transfer methods (convection, conduction, radiation), it is not only fast and uniform, but also clean and sanitary, which is very suitable for cooling cooked food applications, such as precooling of fruits and vegetables.

vacuum pump in vacuum cooling

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)