Vacuum pump pouring in epoxy resin

Many types of epoxy resin can be used in the casting process. However, due to the limitations of technical and technological conditions, the material properties of epoxy resin are very strict. If the content of organic chlorine and inorganic chlorine is required to be low, the electric properties of cured epoxy resin will be reduced at high temperature if the content of organic chlorine in epoxy resin is high; if the content of inorganic chlorine in epoxy resin is high, the electric properties of cured products of epoxy resin will be deteriorated at room temperature, or the cured products may break. At the same time, due to the presence of impurities such as chloride ion in epoxy resin, the gelation time of epoxy resin mixture in the casting process is shortened, and the casting process can not be carried out smoothly, resulting in premature gelation and scrap.

At present, the epoxy resin used for casting transformer winding is basically liquid bisphenol with medium viscosity! Epoxy. Whether the resin is imported or domestic, its performance is basically the same, all are high-purity epoxy resin.

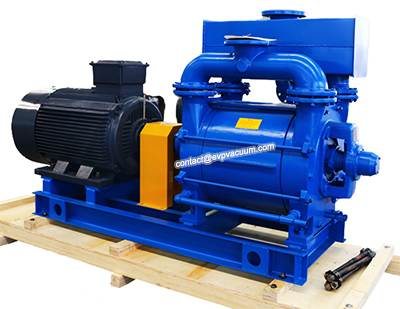

The appearance quality control of casting parts has become a difficult point in casting technology. Therefore, in order to solve this problem, EVP water ring vacuum pump manufacturer has studied and obtained the solution about the application of vacuum pump in epoxy resin pouring.

Vacuum pouring is the most widely used and mature technology in epoxy resin pouring. For an electrical insulation product poured with epoxy resin, it requires perfect appearance, stable size, qualified mechanical and electrical properties. These properties depend on the design of the parts, the quality of the mould, the selection of the casting materials, the control of the casting process conditions and so on. The key point of vacuum casting of epoxy resin is to reduce the air gap and air bubble in casting products as much as possible. In order to achieve this goal, it is necessary to control the vacuum degree, temperature and process time in each process of raw material pretreatment, mixing and pouring.

Technology and principle of vacuum pump system for epoxy resin pouring

Epoxy resin pouring is a process of pouring epoxy resin, curing agent and other materials into a set mold, and curing them into thermosetting products by crosslinking with thermoplastic fluid. Because epoxy resin casting products have excellent electrical and mechanical properties, it has been widely used and developed in the electrical industry.

Compared with traditional insulating materials, vacuum system technology for epoxy vacuum casting products has many unique advantages:

1. No air gap or little air gap, excellent electrical insulation performance of products;

2. Good fluidity of casting, natural filling cavity, good uniformity of products;

3. Due to the good electrical performance, the product can be miniaturized and the host structure optimized;

4. The product can be made into complex shape, and one-time forming, with good integrity of metal inserts and insulation materials;

5. Good weather resistance, can be applied to indoor and outdoor fields;

6. The product is solid, flame-retardant, safe and convenient to use.

Through the analysis of the application of vacuum pump in epoxy resin pouring, we can know that the development of epoxy resin pouring from atmospheric pressure molding to vacuum molding. Vacuum casting makes the bubbles in the castable easier to be discharged, the internal quality and appearance quality of the products are greatly improved, thus promoting the development of power transmission and transformation technology.