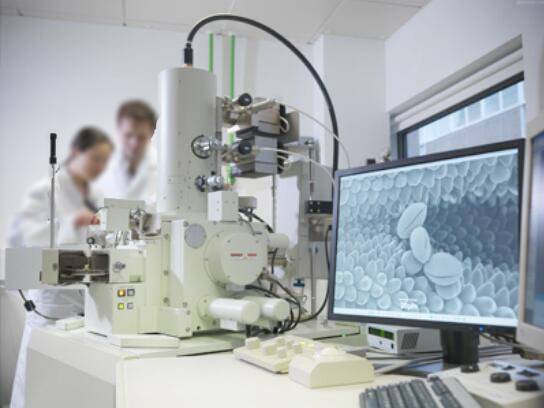

Vacuum pump used in Analytical instrument industry

The analytical instrument industry that needs to operate under vacuum is one of the largest and most complex markets for vacuum equipment. This market includes:

Surface analysis instruments, gas analysis instruments, mass spectrometers, leak detection instruments, and other analytical instrument applications.

EVP has developed a series of molecular pumps dedicated to the analytical instrument industry for the small size, high performance and high reliability of vacuum products in the analytical instrument industry. With compact design, ultra-quiet operation and stable operation under high pressure, it has won the trust of customers .

The demand for vacuum technology in the field of analytical instruments is very complex. Not only does it have high requirements for cost control, but it also has high requirements for performance and space constraints.

In order to meet the vacuum requirements of analytical instruments and system engineering, they must be taken into consideration in the design stage. And to achieve higher sensitivity, resolution and sample throughput, significantly improve data management and other goals, and optimize the cost and space in the new analysis system, this is the only way. In this process, special attention must be paid to the vacuum system. It is necessary to consult the professional opinions of vacuum experts as soon as possible in order to maximize the integration of vacuum technology into the existing system.

The requirements for new systems are constantly increasing, and it needs to be compatible with neighboring modules. Typical applications such as liquid chromatography mass spectrometers or gas chromatography mass spectrometers may not require the vacuum system itself. However, for ionization processes such as chemical ionization (CI) and plasma ionization (ICP), or in the presence of critical gas components of analytes and reactants, the demand for vacuum technology will increase significantly. The main application areas and growth markets of mass spectrometry include the environmental technology and biomedical sectors, especially the protein and genetic research fields. In addition, the principle of mass spectrometry is also used in applications in the pharmaceutical industry and residual gas analysis.

Numerous new developments and technologies have caused tremendous changes in the mass spectrometer market, increasing the range of functions and options of mass spectrometers. The promotion of new development results is not only determined by technology, but also by new needs in the fields of health and environmental engineering. However, even if more technologies are available, the industry is still willing to regard these as challenges and continue to develop.

Driven by these new applications, the demand for vacuum systems is also growing, requiring higher throughput and resolution. Especially for low-cost, high-efficiency and compact solutions, there is a high demand.

The traditional technology uses a variety of high vacuum pumps with different pumping speeds to realize the vacuum system, such as the sample chamber cavity, part of the multi-stage ion optical device, and the detector system of the mass spectrometer. Turbo molecular pumps are mainly used for this purpose, while separation pumps are used for different vacuum degrees and air flow rates.

At least two high vacuum pumps with a pumping speed between 50 and 300l/s are required. These pumps also need to use small mechanical foreline pumps for rough pumping, such as rotary vane pumps. The exhaust air source also requires an additional vacuum pump. Depending on the requirements, a total pumping speed of at least 30 m³/h or more must be achieved. This solution requires a lot of space. Due to the large number of independent components, the reliability of the overall system is reduced.

The development of the pump requires a combination of precise geometric adaptability and excellent performance in a single vacuum system. Especially in terms of increasing complexity and the trend of desktop devices, this concept fully meets market requirements and customer needs. In addition to pure geometric adaptability, specific vacuum technical parameters need to be met. For example, by combining different pumping principles, the allowable front vacuum pressure will be significantly increased, while the compression performance will be improved by several orders of magnitude. By cleverly designing the rotor geometry, up to three different pump stages can be produced, and their orientation will only partially affect each other. This arrangement makes it possible to replace two discrete high vacuum pumps and a mechanical backing pump.

Such a design can even be fully integrated into the vacuum chamber of the analytical instrument. This requires close cooperation between the system manufacturer and the vacuum supplier from the very beginning. It is very important to improve suggestions during the design phase. Depending on the configuration of the system, the result can often be about 50% less space for the vacuum system, and more than 50% cost savings.

High reliability can be achieved through optimized bearing technology. This technology uses maintenance-free magnetic suspension bearings and precision ball bearings to locate the rapidly rotating rotor on both sides, which can effectively reduce vibration.

The pump is supplemented with a corresponding electronic drive unit and a series of accessories. For the integration of computer control of turbomolecular pumps, a standardized interface is provided. Due to their special layout, these pumps only require an air cooling system, which means that additional water cooling and other equipment costs can be saved.

The early integration of innovative turbomolecular pumps in the design of modern mass spectrometers can achieve significant cost and space savings. In addition, the overall system reliability has also been improved. Customized vacuum solutions have also become more reliable.

Copyright: EVP Vacuum Pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)