Vacuum pumps are used in the coal industry

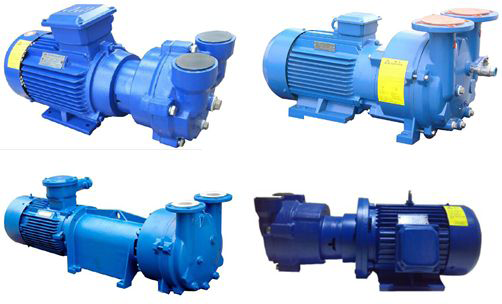

Coalbed methane is generally adsorbed on the coal seam, which has to go through three production processes: drainage, pressure reduction and gas recovery. The vacuum pump used in coal mine.

Safety, complete set, automation and high reliability are the basic requirements of coal industry for vacuum pump. Traditionally, give priority to with vacuum pump equipment manufacturers, such as: pre separator, tempering prevention device, gas separator, electric control, sensors, instrumentation, etc is configured by the coal mining enterprises, such not only embodied in specialized degree is low, but also due to the mismatch of the configuration of main equipment efficiency is low, and even may be due to the difference of professionalism, equipment can’t work normally. Therefore, equipment integration is the development direction of vacuum equipment in the application of coal industry.

In the coal industry, vacuum pumps are used for the extraction and transportation of gas gases, as well as for coal washing, chemical engineering, drying and well production. In view of these particularities, providing personalized vacuum equipment is also the direction of product development in the vacuum equipment manufacturing industry. Vacuum industry manufacturers are committed to the research and development of safety, energy saving, environmental protection, chemical and other equipment in China’s coal industry. They have developed a complete set of vacuum units integrating machinery, electric equipment and instruments, equipped with complete soda separators, circulating heat exchangers, on-line measuring and controlling instruments, automatic control systems and valve components.

The vacuum unit, dry equipment and negative pressure generating center, which have been put into use now, are all suitable for the needs of the coal mine industry. They are equipped with complete water vapor separator, circulating heat exchanger, on-line measuring and controlling instrument, automatic control system and valve assembly.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)