Vacuum pumps for lithium batteries

Development of Lithium Batteries

China is currently the second largest CO2 emitter in the world, and shows an upward trend. It is predicted that China will become the world’s largest CO2 emitter in many years. Therefore, China is facing increasing pressure to reduce carbon emissions. According to the statistics of OICA, automobile exhaust has accounted for 16% of the total CO2 emission. Therefore, it is imperative to promote the use of clean energy vehicles.

Batteries are the biggest bottleneck in the technology and cost of new energy automobiles. They are also the most profitable link in the new energy automobile industry chain, and the profitable profits will be maintained for a long time. The power battery industry is growing from scratch, and its market capacity is about 32.5 billion from the current billion to 2018. It will grow rapidly in the next few years. The huge growth space will benefit the whole industry chain.

There is a complete domestic lithium battery industry chain. BYD, Bike and other companies are in the forefront of the global lithium battery industry, and they are not lagging behind foreign manufacturers in the key battery composition areas of power batteries (BYD is the first commercial plug-in hybrid vehicle F3DM in the world, Tianjin Lishen will cooperate with Meyer to produce power batteries). The overall scale and technical competitiveness of the industry is not high. Obviously lagging behind foreign countries.

Rotary vane vacuum pump for lithium batteries

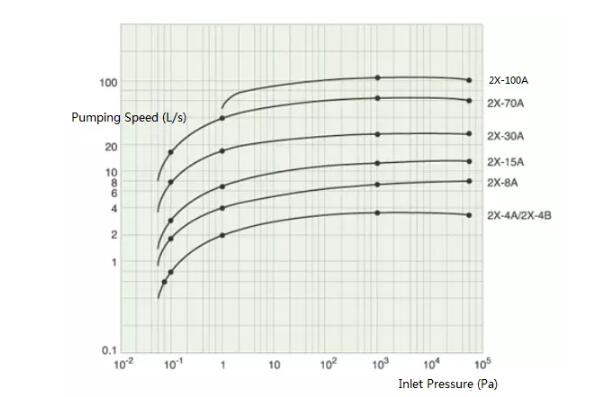

The ultimate pressure of rotary vane vacuum pump for lithium battery vacuum pumping can reach 0.06pa. the maximum pumping speed is 100L ·m ·L ~ (- 1) ·h ~ (- 1).

Product parameters

| 2X-4A | 2X-8A | 2X-15A | 2X-30A | 2X-70A | 2X-100A | |||

| Pumping speed(L/s) | 4 | 8 | 15 | 30 | 70 | 100 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ²(5×10-4Torr) | ||||||

| Total pressure | 2.66(2×10-2 Torr) | |||||||

| Rotary speed(r/min) | 450 | 320 | 320 | 450 | 420 | 360 | ||

| Motor power(Kw) | 0.55 | 1.1 | 2.2 | 3 | 5.5 | 7.5 | ||

| Working voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Cooling Mode | Natural cooling | Water cooling | ||||||

| InletDiam(mm) | I.D. | 25 | 40 | 50 | 65 | 80 | 80 | |

| O.D. | 30 | 50 | 80 | 85 | 100 | 125 | ||

| Dimensions(mm) | Length | 540 | 790 | 790 | 810 | 910 | 1130 | |

| Width | 335 | 430 | 530 | 480 | 650 | 740 | ||

| Height | 380 | 540 | 540 | 560 | 700 | 690 | ||

| Oil capacity(L) | 1.0 | 2.0 | 2.8 | 3.0 | 4.2 | 5 | ||

| Recommend solenoid valve | DDC-JQ25 | DDC-JQ40 | DDC-JQ40 | DDC-JQ65 | DDC-JQ80 | |||

| Noise (dB A) | 65 | 70 | 70 | 70 | 75 | 90 | ||

| Weight(kg) | 60 | 158 | 202 | 230 | 480 | 560 | ||

The use of rotary vane vacuum pump for lithium battery vacuum pumping:

1, always pay attention to the oil level.

2. After the lithium battery is vacuumized, the valve can be opened slowly after the rotary vane vacuum pump is started.

3, often pay attention to whether the rotary vane vacuum pump for lithium battery vacuum pumping is running normally, whether there is special sound or not, whether the motor is overloaded or not.

4, notice if the cooling water is interrupted.

5. Note that the temperature rise of the pump is not more than 40 ℃.

6. If the pump temperature drops below 5 ℃ after stopping, the inner cooling water of the rotary vane vacuum pump for lithium battery vacuum pumping must be removed.

The main characteristics of rotary vane vacuum pump for lithium battery vacuum pumping:

1. Dongshan rotary vane vacuum pump is provided with air ballasting valve, which can remove a small amount of water vapor;

2. The limit vacuum degree of the rotary vane type vacuum pump for lithium battery is high;

3.Internal forced oil feeding, full lubrication, reliable performance;

4. The double safety device is provided with automatic non-return oil.

5. The rotary vane vacuum pump used for vacuum pumping of lithium battery can still operate continuously when the inlet pressure is 1.33 × 10Pa.

6. Do not spill oil, do not spray oil, do not pollute the working environment.

Performance curve

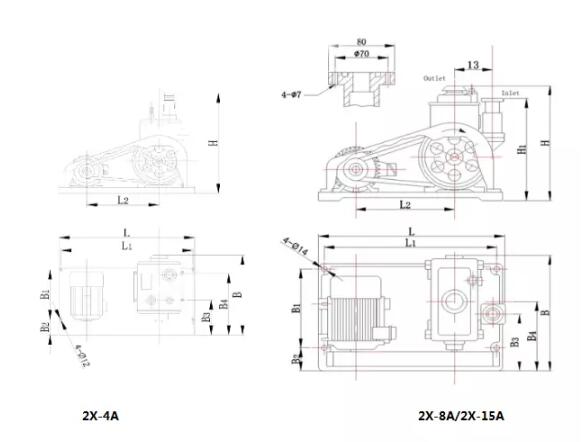

Installation dimension

Maintenance of rotary vane vacuum pump for lithium battery vacuum pumping:

1. The rotary vane vacuum pump for lithium battery vacuum pumping shall always be kept clean and no other objects shall be placed on the pump.

2, note whether the belt tension is appropriate, the half-year adjustment.

3, whether the pipe joint is leaking or not, put an end to it in time.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)