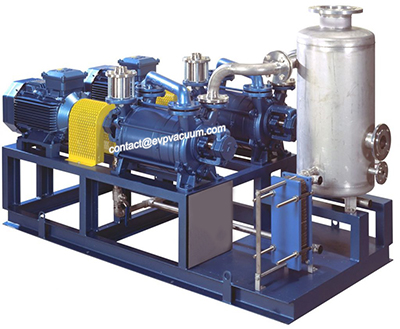

vacuum system installation and commissioning

Leak detection of vacuum system installation and debugging design

The vacuum system has strict requirements for tightness, so the leak detection work is needed in every stage of vacuum system design. The installation and debugging stage is the main body of vacuum equipment or system leak detection. Therefore, EVP vacuum pump manufacturer will talk about what should be paid attention to during vacuum system commissioning.

In the process of vacuum system installation and commissioning, it is the key point of leak detection to check and ensure the tightness of the connection parts. The premise is that the tightness of the vacuum equipment weld has passed the leak detection in the processing stage before, so as to avoid multi-faceted leak detection at the same time, resulting in increased workload and difficulty. For large and complex vacuum equipment, it is better to use sectional leak detection. After each stage is completed, the corresponding connecting parts and welds will be detected once, and the next step will be carried out after meeting the requirements. Specific needs to pay attention to the following aspects:

First, understand the structure and assembly process of the vacuum pump to be inspected. Master the requirements of the vacuum pump and find out the key suspicious parts requiring leakage detection.

Secondly, according to the requirements of the maximum allowable leakage rate of the vacuum system in practical application and whether it is necessary to find the specific location of the leakage hole, starting from the principles of economy, speed and reliability, correctly select the leakage detection method or instrument, prepare the equipment required for the leakage detection, and formulate the feasible leakage detection procedure.

Third, clean the inspected parts, take out the welding slag and oil dirt, clean them according to the requirements of vacuum sanitary conditions, and dry them. For small devices with high requirements, they can be baked by vacuum oven after cleaning. This is mainly to prevent the leakage from being blocked by dirt, oil, organic solution, etc., and to protect the leakage detector.

Fourth, after the determination of the leak detection method and equipment, it is necessary to calibrate the leak detection sensitivity and determine the leak detection time of the leak detection system.

Fifthly, if the vacuum leak detection method is used, in order to improve the sensitivity of the instrument, the tested parts should be evacuated to a higher vacuum as much as possible.

Sixthly, on the premise of meeting the requirements of vacuum system, the economic and on-site qualified leak detection method is preferred.

Seventh, when using helium mass spectrometer leak detection equipment, for the tested parts that require low leak detection or have large leak, try to use low concentration helium gas for leak detection at the initial stage of leak detection, and then carry out small leak detection to save helium.

Eighth, for the large leak detected, it is necessary to repair the plug in time before the small leak detection.

Ninth, the leakage detected and repaired shall be rechecked to ensure that the leakage detection results meet the requirements.

In addition to the leak detection work in each stage, the vacuum system should maintain good routine leak detection habits in the application, form a standard, and ensure the good operation of the vacuum system.