vacuum valve connection method

There are many kinds of vacuum valves, which play an important role in the vacuum system. They are usually classified according to their functions, structural types, driving modes, materials and uses. This paper describes five common types of vacuum valve connection.

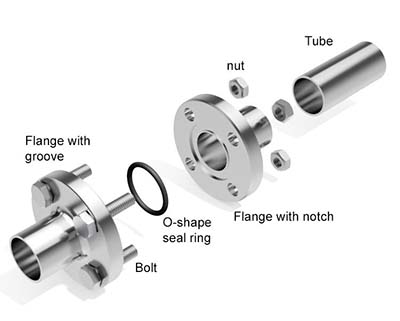

1. Flange connection

This is the most commonly used form of connection in valves. According to the shape of the joint surface, it can be divided into the following categories:

1) Smooth type: used for valves with low pressure. Easy to process

2) Concave convex type: high working pressure, medium hard washer can be used

3) Mortise and groove type: the washer with large plastic deformation can be used widely in corrosive medium, and the sealing effect is good.

4) Trapezoidal groove type: oval metal ring is used as gasket for valve with working pressure ≥ 64kg / cm2, or high temperature valve.

5) Lens type: gasket is lens shape, made of metal. For high pressure valve with working pressure ≥ 100kg / cm2, or high temperature valve.

6) O-ring type: This is a relatively new form of flange connection. It is developed with the emergence of various rubber O-rings. It is more reliable than the ordinary flat gasket in sealing effect.

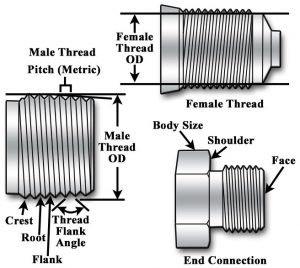

2. Threaded connection

This is a simple connection method, commonly used for small valves. There are two situations:

1) Direct sealing: internal and external threads directly play a sealing role. In order to ensure no leakage at the joint, lead oil, thread hemp and polytetrafluoroethylene raw material belt are often used for filling. Among them, polytetrafluoroethylene raw material belt is widely used. This material has good corrosion resistance, excellent sealing effect, convenient use and preservation. When disassembling, it can be completely removed, because it is a layer of cohesionless film, which is much superior to lead oil and thread hemp.

2) Indirect sealing: the force of thread tightening is transmitted to the gasket between two planes, so that the gasket plays a sealing role.

3. Ferrule connection

Ferrule connection has been developed in recent years in China. Its connection and sealing principle is that when the nut is screwed, the ferrule is under pressure, making its edge bite into the outer wall of the pipe, and the outer cone of the ferrule fits with the inner cone of the joint under pressure, so it can reliably prevent leakage.

The advantages of this connection form are:

1) Small size, light weight, simple structure, easy disassembly;

2) Strong connection force, wide range of application, can withstand high pressure (1000 kg / cm2), high temperature (650 ℃) and impact vibration;

3) Various materials can be selected, suitable for anti-corrosion;

4) The requirement of machining accuracy is not high;

5) Easy to install at height.

At present, the form of ferrule connection has been used in some small caliber valve products in China.

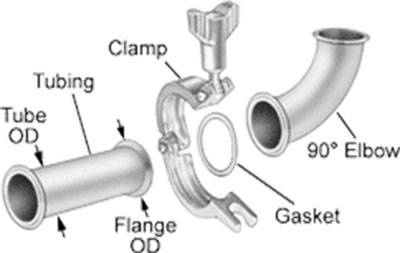

4. Clamp connection

This is a fast connection method, it only needs two bolts, which is suitable for low-pressure valves that are often disassembled.

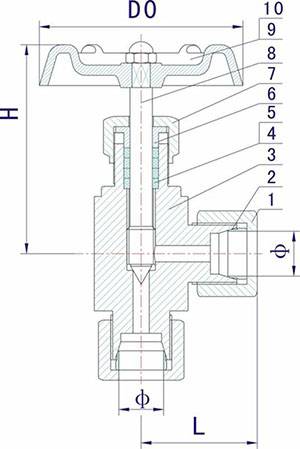

5. Inner self tight connection

All the above connection forms use external force to counteract the medium pressure and realize sealing. The following describes the use of medium pressure for self tightening connection. The sealing ring is installed at the inner cone, and the side opposite to the medium forms a certain angle. The medium pressure is transmitted to the inner cone, and then to the sealing ring. On the cone at a certain angle, two components are generated, one is parallel to the center line of the valve body and the other is pressed to the inner wall of the valve body. The latter component is the self tightening force. The greater the medium pressure, the greater the self tightening force. So this kind of connection is suitable for high pressure valve. Compared with flange connection, it saves a lot of materials and manpower, but also requires a certain amount of pre tightening force, so that it can be used reliably when the pressure in the valve is not high.

The valve made of self tightening sealing principle is generally a high-pressure valve.

There are many forms of valve connection, for example, some small valves that do not need to be removed are welded with pipes; some non-metallic valves adopt socket connection, etc. Valve users should be treated according to the specific conditions.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)