Water Ring Vacuum Pump Chemical processing plant

Water Ring Vacuum Pump Summary

Water ring vacuum pump is a wet vacuum pump, which can cause the highest vacuum of 85%. Water-ring vacuum pump can be used as a blower if the suction port is opened to the atmosphere and the pressure outlet is opened to the equipment or system, which can produce compressed gas below lat(gauge pressure). As the water-ring vacuum pump fills water continuously to keep the liquid seal, it will also have the effect of cooling the pump body. If the circulating water is changed to other liquids, it will be called liquid-ring pump, which has been introduced before.

The water ring vacuum pump has simple structure, compactness, easy manufacture and maintenance, long service life and reliable operation due to mechanical friction in the rotating part. Suitable for suction of gases containing liquids. It is more suitable for suction of corrosive or explosive gases, but its efficiency is very low, about 30-50%. The resulting vacuum is also affected by water temperature. However, due to the above advantages, most of them are used in chemical production.

Water ring vacuum pump and compressor are widely used in petrochemical, pharmaceutical, food, sugar industry and other fields. Because the gas compression process is isothermal in the working process, it is not easy to occur danger when compressing and pumping flammable and explosive gases, and its application is more extensive.

Water ring vacuum pump structure and characteristics :

Coaxial direct connection design of pump saves space and is easy to install.

Mechanical seal is used as standard configuration, eliminating leakage and easy maintenance.

It runs smoothly and the noise can be as low as 62 decibels.

Unified corrosion resistance design, bronze impeller improves the corrosion resistance of the pump, such as the use of stainless steel material is more suitable for more demanding applications.

Unique flexible exhaust design, will not produce over-compression, ensuring the best efficiency of 2BV in its performance range.

Water Ring Vacuum Pump in Chemical Plant Working Principle

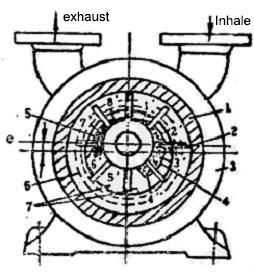

The structure and working principle of the water ring vacuum pump are shown in Figure 1. An impeller 2 is eccentrically installed in the pump housing 1, and there are several blades on the impeller. Before starting, the pump is filled with a certain amount of water. After starting, the impeller rotates with water. Under the action of centrifugal force, the water is thrown to the shell wall to form a water ring with a certain thickness. Because the impeller is eccentrically installed in the pump shell, the sealing volume of the water ring and the blade is gradually increased from the right side of the impeller, and then gradually reduced to zero as the impeller rotates. When the enclosed volume increases gradually, the gas is inhaled by four crescent-shaped suction ports on the end cap. After turning the bottom midpoint, the enclosed volume decreases gradually, and the gas is discharged through the outlet 5.

Fig. 1 Working Principle of Water Ring Pump

1-pump case; 2-impeller; 3-end cover; 4-suction hole; 5-discharge hole; 6-liquid ring; 7-studio

The pump has simple structure, stable and reliable operation, and is suitable for suction of gases with liquids. It is widely used in chemical production to suck inflammable, explosive and corrosive gases. Because the impeller continuously drives the water ring to rotate, the resistance loss is great and the efficiency is low, generally 30-50%.