water ring vacuum pump condenser

Vacuum pumps play an important role in condensing steam turbines. Before start-up, vacuum pump extracts gas from condenser to establish vacuum. During start-up and operation, vacuum pump extracts non-condensable gas which leaks or carries working substance into condenser to enhance the condensation effect of steam.

Water ring vacuum pump has the characteristics of simple structure, economical operation and wide application range.

一. Water ring vacuum pump working principle and Structure

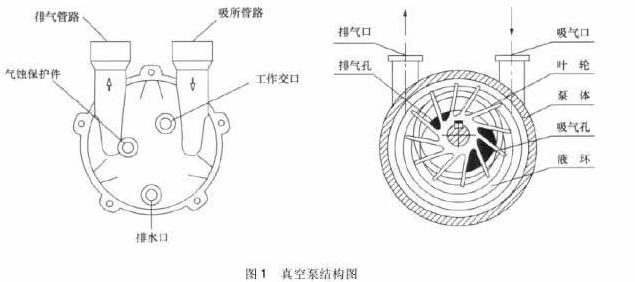

Water ring vacuum pump is composed of impeller, pump body, suction and exhaust outlet, auxiliary pipeline and so on. The concrete structure is shown in the figure.

The eccentric impeller is installed in the pump body. When the impeller rotates, under the action of centrifugal force, water is thrown around, forming a closed water ring similar to the shape of the pump chamber. The outer surface of the water ring contacts with the pump chamber, and the inner surface contacts with the blade. A number of small crescent cavities are formed between the impeller hub and the water ring. When the impeller rotates clockwise, due to the eccentric arrangement, the volume of a single small chamber increases from small to large, and the pressure in the chamber decreases continuously. When the pressure is lower than the gas pressure in the pumped container, the gas enters the small chamber from the suction port, which is the process of suction.

As the impeller continues to rotate, the volume of the small chamber gradually decreases and the pressure increases until the pressure of the gas is stronger than the exhaust pressure, and the compressed gas is discharged from the exhaust port. In this way, during the continuous operation of the pump, the gas is continuously inhaled and discharged along the axial direction of the impeller, thus achieving the purpose of continuous steam extraction.

二, improvement measures

1.Installing Atmospheric Ejector

The operation noise and impeller cavitation of water-ring vacuum pump occur when it is running. It is generally believed that the inlet pressure of vacuum pump is too low (lower than the saturation pressure of working fluid), which leads to the vaporization of working water in the pump body. The specially designed cavitation protective tube leads air from the exhaust to the high vacuum chamber in the pump to prevent cavitation. At the same time, a layer of gas protective film is formed on the surface of the impeller to prevent the impeller from being damaged when cavitation occurs.

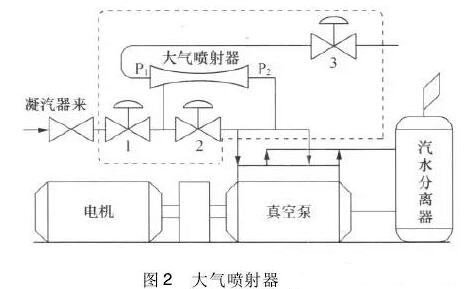

Atmospheric ejector is a scaled nozzle, designed for supersonic-sonic-subsonic conditions. Under adiabatic conditions, the change of fluid pressure is inversely proportional to the change of flow velocity. The divergent nozzle can get a lower inlet pressure under certain outlet pressure.

Three pneumatic valves are operated with an air ejector. In the initial stage, valve 1 and valve 2 are opened, valve 3 is closed, and vacuum pump extracts gas from condenser to establish vacuum.

When the vacuum reaches a higher fixed value, the valve 2 closes and the valve 3 opens, and the external air flows into the air ejector at high speed under the action of pressure difference, forming supersonic flow at the inlet along with the high-speed air flow from the condenser, and finally flows into the vacuum pump through the retractable nozzle.

In this way, the working pressure of the vacuum pump (that is, the outlet pressure of the atmospheric ejector) can be maintained at a relatively low safety value, while the inlet of the atmospheric ejector produces a higher vacuum.

2.Improvement of working fluid cooling water system

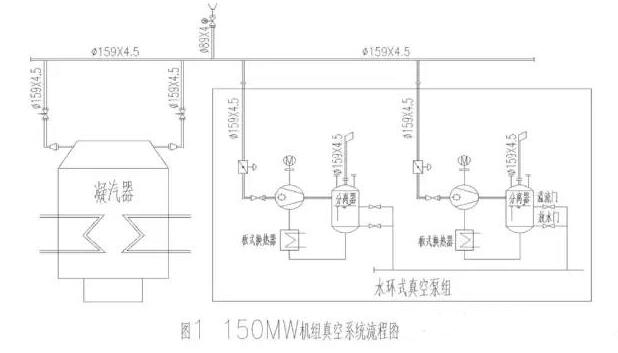

The design of working fluid cooling water for vacuum pumps in some power plants is provided by the condenser circulating water system as shown in the figure. The high temperature in summer can not achieve the cooling effect.

The cooling water can be changed to be supplied by the industrial water system of the unit. Industrial water is the source of water, and the water temperature is low. On the one hand, it can improve the working efficiency of the vacuum pump, and also improve the working conditions of the vacuum pump to avoid cavitation.

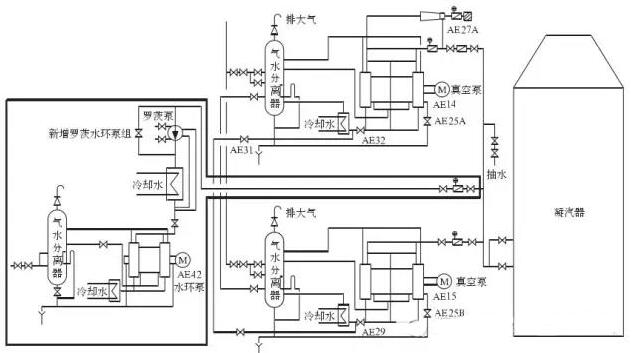

3.Roots-Water Ring Vacuum Pump Unit Application

A power plant uses two-stage pumps of Roots water ring pump, which are connected to the steam extraction main pipe and used in parallel with the original two vacuum pumps. The reformed vacuum pump system is shown in the following figure. Roots pump, as the main pump, compresses the non-condensable gas and some water vapor extracted from the condenser and discharges them into the cooler. A low-power water-ring vacuum pump is used to extract the gas from the cooler and discharge it into the steam-water separator. A bypass pipe and a manual door are added to the Roots pump inlet.

When the unit starts up, the vacuum of the unit is quickly established by using the original vacuum pump. After the vacuum is established, it is switched to Roots-Water Ring Pump Unit to maintain the vacuum of the unit.

3.Common failures

1.Pipeline water accumulation

Due to the direct connection between vacuum pump and condenser, some steam inevitably exists in the intake pipe. When the vacuum pump shuts down, the steam condenses into water in the pipeline and accumulates in front of the inlet valve. When the vacuum pump is restarted, water enters the vacuum pump, which easily causes excessive current. If the water volume is too large, it will endanger the safe operation of the motor. In order to avoid the above hazards, the inlet valve should be opened manually before starting for drainage. For the case that two vacuum pumps are used as one, the starting sequence should be reasonably designed to prevent similar situations from occurring.

2.Insufficient water supply

The working water of the water-ring vacuum pump comes from the steam-water separator. The pressure difference between the pump body and the steam-water separator ensures that the lost working water can be replenished in time, thus maintaining the normal thickness of the water-ring. Once the water supply is insufficient or the water supply pipeline is blocked, the water ring will be destroyed. The effective working chamber between the impeller hub and the water ring of the pump will not be formed, and the output of the pump will be reduced, thus affecting the vacuum of the unit. In order to ensure safe operation, the steam-water separator has two water supply loops from different water sources, which can be manually cut to the other loop in case of one fault. At the same time, the high and low liquid level alarm of the steam-water separator is set up to detect and deal with the malfunction in time. Vacuum pumps should be regularly repaired, and proper methods should be adopted to clean the internal pipelines to ensure the smooth flow of the whole water supply circuit.

3.Trouble of Atmospheric Ejector

In order to prevent impurities from entering the vacuum pump and damaging the impeller, an air inlet filter is installed at the inlet of the air ejector. When the filter is blocked, the amount of air entering the air ejector is insufficient, the design flow characteristics are destroyed, the safety of the vacuum pump and the vacuum of the condenser will be affected. For this reason, a three-way valve is installed at the intake end of the atmospheric ejector. One end is connected with the atmosphere through a filter, the other end is directly connected with the upper part of the steam-water separator. When the filter is blocked, the three-way valve can be cut to the steam-water separator, and the gas can be directly extracted from the outlet of the vacuum pump to operate, thus improving the safety performance of the vacuum pump.

In the vacuum establishment stage, valve 1 and 2 are opened and valve 3 is closed; in normal operation, valve 1 and 3 are opened and valve 2 is closed. If the valve condition is incorrect or the valve leakage seriously causes the valve 2 and 3 circuits to operate simultaneously, the air ejector will be bypassed, and the vacuum of the condenser will be reduced to the design pressure of the vacuum pump. When the leakage is serious, the air flowing back to the condenser beyond the output range of the vacuum pump will cause more accidents.

4.When using Roots Water Ring Pump Unit, attention should be paid to the frictional vibration phenomenon when the ambient temperature is high or the cooling water temperature is high. If Roots pump trips alone, it will lead to lower inlet pressure of water ring pump and increase the vibration of water ring pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)