water ring vacuum pump in candy production of application

Hard candy is the hardest kind of candy. It is boiled at high temperature and has a low water content. Its obvious characteristics are that it is brittle and mostly transparent and glass-like. Hard candies are divided into different categories according to different crafts, shapes, packaging, color and flavor, while fruit hard candies are named after their flavors. Due to the wide variety of fruits, the corresponding fruit hard candies are also numerous, forming a series.

For example, cream black tea hard candy, which is characterized by cream black tea hard candy is a combination of Chinese and Western products. It is based on hard candy, and is prepared by adding black tea cooking liquid and mixing with honey, fruit acid and other materials to make full use of tea. Pharmacological effects, promote digestion, enhance immunity, candy with health care functions. Its taste adopts the European and American milk tea flavor, which is different from the general candy containing tea ingredients.

The ingredients include white sugar, starch syrup, black tea juice, honey, condensed milk, cream, citric acid, lecithin, black tea essence, etc.

Process flow: filtration → vacuum distillation→ seasoning → cooling→ stretching → forming → packaging → finished product

Operation points

(1) Carry out according to the technological procedure of toffee dissolving sugar. The white sugar, starch syrup, water, condensed milk, and cream are added together to melt and filter, then together with honey, emulsifier, and black tea juice, it is emulsified and homogenized by a high-cut shearing machine or a colloid mill into a homogeneous emulsion. boil.

(2) Preparation of black tea juice Black tea juice can be boiled with crude black tea leaves and water, and the tea juice can be extracted by a press when the solid content reaches about 8%.

(3) Pumping the above-mentioned emulsified and homogenized mixed sugar solution into a continuous vacuum sugar boiling pot for cooking. The boiling temperature should be controlled at 138~142℃, and the vacuum degree should be kept above 0.09MPa G.

(4) Correctly grasp the temperature of the massecuite during the seasoning, that is, after turning it over, add citric acid and black tea essence and stir evenly. The temperature at this time is 120 °C. The essence should be added after the massecuite has cooled slightly to prevent the essence from volatilizing. During operation, citric acid and essence should be avoided to be lost on the table, and the phenomenon of adhesion on the table should be prevented. During the cooling process, the cooling surface should be folded inward repeatedly, and the generation of air bubbles should be destroyed from time to time, until the massecuite has good plasticity.

(5) After the candy bar is evenly stretched according to the requirements of the hard candy forming process, it is then punched into the required shape, and it can be packaged after it is slightly cooled and slightly warmed.

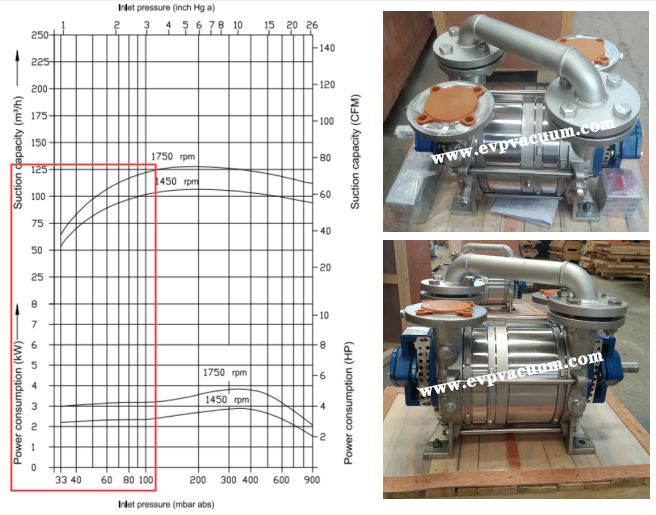

During the whole vacuum cooking process, the sugar boiling temperature must be stable, the vacuum pump must not be shut down at will, and the vacuum degree should be kept above 0.09MPa G. The pumping speed performance of the selected vacuum pump is extremely important. In the food industry, the material of the vacuum pump that is required to be selected should also conform to the food-grade stainless steel material.

The water ring vacuum pump of Shanghai EVP Vacuum Solution has been successfully used in the largest food factory in Armenia. In the vacuum distillation production, compared with single-stage vacuum pumps, EVP high-performance DLV two-stage water ring vacuum pump can maintain higher pumping speed requirements. The following is the product shipment photo of DLV-110 dual-stage water ring vacuum pump.

Welcome to consult EVP at any time.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)