Water ring vacuum pump in the production of egg tray from waste paper

As we all know, most of the egg trays are made from waste paper, and the egg tray machine integrates these fertilizers to form an egg tray, which not only reduces the waste of resources, but also protects the environment, in line with contemporary people’s concept of life. In today’s society, egg food is indispensable in daily life. With the increasing sales of eggs, it also drives the use of by-products (egg trays). Egg trays are indispensable when they are transported, and the sales volume of egg tray manufacturing industry is also increasing.

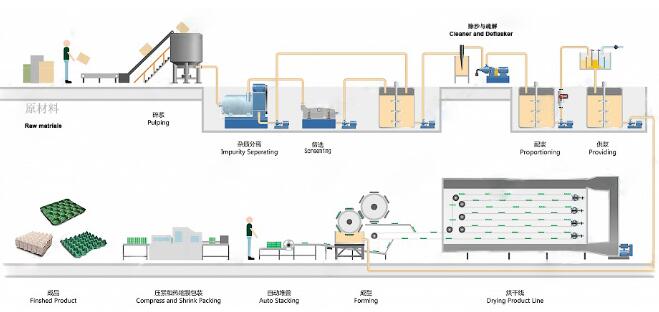

When it comes to the production of environmentally friendly egg tray from waste paper waste utilization, we must talk about the working process of the egg tray machine. Simply speaking, waste paper is added to the pulper and transported to the pulp storage tank with water. The pulp from the pulp storage tank is evenly stirred by a blender and transported to the pulp supply tank. The pulp from the pulp supply tank is stirred to a certain concentration and transported to the molding machine. The molding machine produces egg tray and the conveyor belt passes through the drying hole, just dry the egg tray and pack it. In addition, through the vacuum pump, the unused water in the molding machine can be pumped to the return pool, and the return pool can be transferred to the pulper and pulp storage pool to recycle the water and reduce the waste of resources. The design and manufacture of the egg tray mold is a key to the appearance and stiffness of the egg tray products. The selection and appearance of the egg tray machine depends on the design of the mold. Because the appearance and size of the egg tray products are based on the mold, the vacuum adsorption molding process is particularly important, so we must choose the best in the process of mold design and matching the EVP Liquid ring vacuum pump system of the egg tray products. Some Pictures as follow:

(Egg tray machine picture: )

(2BE3 series single stages liquid ring vacuum pump picture:)

The production process of egg tray usually includes four parts, namely, pulp, vacuum molding, drying and Vacuum packaging. The egg carton manufacturing machine is a new type of pulp molding production line transformed from egg tray equipment, covering the production process of paper egg tray machine. Therefore, the production process of egg box needs to add hot pressing process after the egg tray is dried, then packed by EVP rotary vane vacuum pump. EVP water ring vacuum pump can pump the unused water from the molding machine to the return tank, which can deliver water to the pulper and storage tank to recycle the water and reduce the waste of resources

The following is the technological process of egg box:

1.Pulping system

Pulping system is the first step of pulp molding process, and even an important part of the whole paper industry. The purpose is to make waste paper into pulp. Usually, in this process, the raw materials of egg tray and egg box (such as waste newspapers, books, office waste paper, etc.) are put into the hydraulic pulper for mixing and crushing, and the smoother and more uniform pulp is obtained through impurity separation, screening, desanding and dispersion. In order to give the product special functions (such as waterproof, moisture-proof, antistatic, etc.), it is necessary to add a small amount of functional additives in the slurry storage tank for slurry preparation, and add clear water and white water for production. Pulp can be used in various production processes, the purity of pulp directly affects the degree of equipment damage, so a strong pulping system is very important for the whole process.

2.Vacuum forming system

The molding system is the second step and the core part of the pulp molding process. The system mainly includes vacuum pump, air compressor, pulp molding machine and cleaning equipment. Among them, the paper pulp molding machine with EVP water ring vacuum pump is the key equipment of the molding system, which is also the direct cause of the different manufacturing processes of egg tray and egg carton. The EVP water ring vacuum pump mentioned here is helpful to the molding of egg tray, while the air compressor is used to remove the wet product from the mold. After the wet embryo is demoulded, the cleaning equipment will quickly and orderly wash to maintain the mold to the machine and ensure the average quality of each final product. In order to ensure the continuity of production, the equipment process needs to be carried out orderly and accurately without interruption. Here are some pictures of vacuum pump of Shanghai EVP company for reference:

CL Series Cone water ring vacuum pump as follow:

3.Drying system

After demoulding the wet embryo, it needs to be dried. In the history of drying technology, there are many drying modes to choose from. The natural drying method of environmental protection and energy saving (i.e. air drying, air drying or sun drying) is usually not selected by the mass business because of its low drying efficiency, so the manufacturers will prefer to choose the efficient drying process within the range of production cost, that is, to use coal, fuel oil and gas as fuel, transfer heat into the drying line through steam, heat transfer oil and other heat media, so as to reduce the production cost The egg box is dried and transferred to the next process.

4.Vacuum Packaging system

Different products need different packaging equipment. The vacuum packaging equipment usually used for egg paper box products are packaging machine, counter and hot press. At the same time, the packaging system is also a different process between the egg tray process and the egg box process. Because the unit price of the egg box is usually slightly higher than the cost of the egg tray, the egg box products are required to have a better appearance and quality. Therefore, before packaging the egg box, we usually set the hot press before the packaging process, and reshape the shape of the egg box products to obtain a higher quality egg box, which we usually use high quality EVP rotary vane vacuum pump, pictures as follow:

Both the early vacuum forming process and the later vacuum packaging process are important processes in the egg tray forming process. Shanghai Kante Vacuum Technology Co., Ltd. has rich experience and can provide the best vacuum pump products and services for customers at home and abroad. Welcome to consult.

Editor by: Shanghai EVP Vacuum Technology Co.,Ltd

Key words: vacuum pump for egg holding machine, water ring vacuum pump, rotary vane vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)