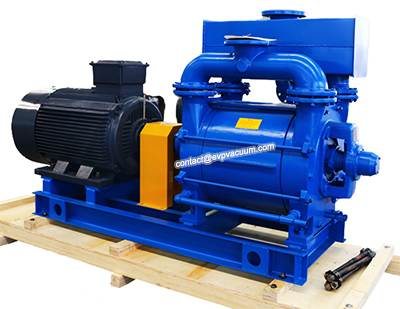

Water ring vacuum pump of milking machine

Milking machine description:

Portable dairy milking machine is an important equipment in the dairy industry, which is widely used in small and medium-sized farms. Personal use is becoming more and more common.

The milking machine is composed of vacuum pump, milk mixer, electric motor, milk barrel, etc. Electric motor can use electric motor, diesel motor and gasoline motor.

The principle of the milking machine is to imitate the physiological action of the calf sucking. The negative pressure is generated by the vacuum pump, the vacuum degree of the milking system is controlled by the vacuum regulating valve, the pulsator generates the milking and rest rhythm, and the air enters the milk collector through the small hole of the milk collector, so as to help the milk to be transported from the milk collector to the milk pipeline.

The main part of the milker is composed of a vacuum pump and a milker. The former mainly includes vacuum pump, motor, vacuum tank, vacuum regulator, vacuum pressure gauge, etc. the latter is composed of milking barrel, pulsator, milk collector, milking cup and some pipes and rubber pipes.

Features:

1. With mobile wheel, mobile milk is convenient and flexible.

2. Operation and maintenance are very simple.

3. Different voltages and motors can be used in different countries.

4. Low noise and high milk yield.

5. Save labor and improve economy.

Conclusion:

1. The value of vacuum pump two-stage AC vacuum pump is mainly used to pump air and other gases with strong corrosion, insoluble in water and less solid.

2. The water input into the pump rotates at high speed to form pressure and form a closed water chamber to take air out of the container at the suction end.

3. Double stage pump, high vacuum, large pumping speed, compact structure, reliable operation, convenient operation and maintenance.

4. Vacuum pump is widely used in food industry, textile industry, pharmaceutical industry, chemical industry, impregnation, drying or other process

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)