Water Ring Vacuum Pump Type

Water Ring Vacuum Pump Types and Principles

1. Water ring vacuum pump products overview:

Water-ring vacuum pumps and compressors are used to suck or compress air and other non-corrosive, water-insoluble, solid-free gases in order to form vacuum and pressure in sealed containers. But inhaled gases allow a small amount of liquid to be mixed. Water ring vacuum pumps and compressors are widely used in mechanical, petroleum, chemical, pharmaceutical, food, sugar industry and electronic fields. Because the compression process of gas is isothermal in the working process, it is not easy to cause danger when compressing and sucking explosive gas. So its application is more extensive. The impeller is eccentrically installed in the pump body. When the impeller is rotated in the graphic direction, the water forms a rotating closed water ring on the inner wall of the pump body under the action of centrifugal force. The upper inner surface of the water ring is tangent to the hub, and the lower inner surface of the water ring is in contact with the top of the blade. At this time, a crescent-shaped space is formed between the hub and the water ring of the impeller, which is divided into several small cavities equal to the number of blades by the impeller. If the starting point is 0 degrees above the impeller, the volume of the small cavity increases from small to large at 180 degrees before the impeller rotates, and is connected with the suction port on the end cover. The gas pressure in the space decreases. At this time, the gas is absorbed, and at the end of the suction, the small cavity is isolated from the suction port. When the impeller rotates from 180 degrees to 360 degrees, the inner surface of the water ring gradually approaches the hub, and the small cavity becomes smaller and larger. When the pressure of the gas in the space rises higher than the pressure of the exhaust port, when the small chamber is connected with the exhaust port, the gas is discharged. Whenever the impeller rotates one week, the space between the blades (small chamber) sucks and exhausts once, and several small chambers work continuously, so that the pump continuously sucks or presses gas. Because in the working process, work produces heat, which will heat the working water ring, and at the same time, part of the water and gas are discharged together. Therefore, in the working process, it is necessary to continuously supply water to the pump to cool and supplement the water consumed in the pump, so as to meet the working requirements of the pump. When the exhaust gas is no longer used, there is a steam-water separator at one end of the exhaust port of the pump (which can be replaced by a water tank made by oneself). After the exhaust gas and part of the water are discharged into the steam-water separator, the gas is discharged from the exhaust pipe, and the water is left in the separator due to gravity and circulated through the return pipe to the pump. With the director of working time, the working fluid temperature will continue to rise. At this time, a certain amount of cold water (tap water can be used) should be added to the steam separator to reduce the working fluid temperature and ensure that the pump can meet the required technical requirements and performance indicators.

2. Water ring vacuum pump characteristics :

Direct-connected water ring vacuum pump can start pumping directly from atmospheric pressure. Coaxial pump, compact structure, easy maintenance, copper impeller material.

3. Water ring vacuum pump working principle :

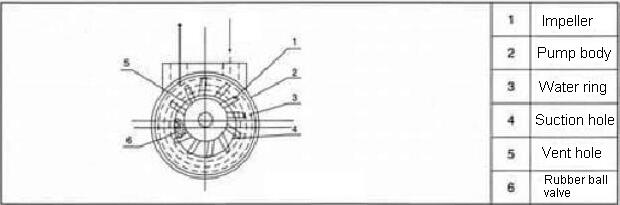

water ring vacuum pump is cantilever structure, as shown in Fig. 1, impeller

(1) Eccentric mounted pump body

(2) Internally, when the impeller rotates, the water is acted by centrifugal force and forms a rotating water ring on the pump wall.

(3) The upper part of the water ring is tangent to the hub and rotates along the arrow direction. During the first half of the rotation, the inner surface of the water ring gradually separates from the wheel, so space is formed between the impeller blades and gradually enlarges, thus gas is inhaled from the suction port. During the latter half-rotation, the inner surface of the water ring gradually approaches the hub, the space volume between the blades decreases, and the gas between the blades is compressed and discharged. 。 In this way, the space area between blades changes once every impeller revolves, the water between each blade reciprocates like piston, and the series of water ring vacuum pumps continuously suck gas. Because in the work, the water will heat, while part of the water and gas are discharged together, so the pump in the work, must constantly supply cold water to cool and supplement the water consumed in the pump. When the exhaust gas of SK series water ring vacuum pump is exhaust gas, a water tank can be connected at the exhaust end. After exhaust gas and part of the water brought out are discharged into the water tank, the gas is discharged by the exhaust pipe of the water tank, and the water falls into the bottom of the water tank and then returns to the pump for use through the return pipe. If the water circulates for a long time, it will heat up, and then cold water with a certain energy will be supplied from the water supply of the water tank.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)