water ring vacuum pump rolling bearing and coupling assembly method

We have learned a lot about the knowledge of water ring vacuum pump. Today, EVP water ring vacuum pump manufacturer will introduce the assembly of rolling bearing and coupling of water ring vacuum pump, and interested partners will have a look.

1、water ring vacuum pump rolling bearing Assembly method

The assembly of the rolling bearing of the water ring vacuum pump depends on the interference between the rolling bearing and the journal or the bearing hole. When the interference is small, press in method is used for assembly. When the interference is large, hot assembly method can be used for assembly.

When the press in method is used for assembly, the copper bar and hammer can be used to knock symmetrically on the inner race with interference in a certain order. In addition, the sleeve made of soft metal can also be driven by hand hammer or press.

When the hot assembly method is adopted, the bearing shall be heated in the engine oil first, and the temperature of the oil shall be below 100 ℃. The bearing shall be put on the journal immediately after being quickly taken out of the oil. The advantage of the hot charging method is that it does not destroy the matching property.

2、water ring vacuum pump coupling Assembly

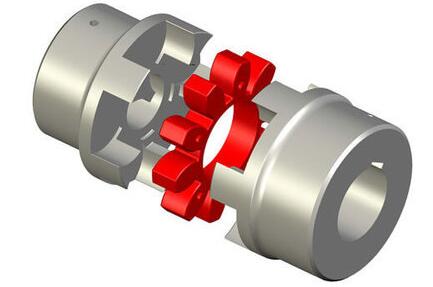

The coupling of water ring vacuum pump is a device that connects the driving shaft and the driven shaft together. It is divided into motor coupling and pump coupling. During installation, the two coupling halves must be concentric, and a certain and equal axial clearance must be maintained between the two ends, otherwise the operation and service life of the machine will be seriously affected. Therefore, the alignment of the coupling is an important part of the assembly work.

Requirements for different shaft degrees of coupling

The axis of pump shaft and motor shaft should be in the same straight line. If there is a certain inclination (i.e. a certain degree of different axis), the machine will run unevenly, generate vibration and noise, cause bearing wear, and affect the service life of the machine. Therefore, when installing the two coupling halves, there should be requirements for different shaft degrees.

Since the outer circle dimensions of the two coupling halves are equal, different shaft degrees can be checked through the outer circle. The inspection method is to place a ruler on the outer circle of the two coupling halves, and observe whether the ruler is close to the outer circle of the two coupling. If it is close to one coupling extractor and has a gap with the other coupling, it means that the two coupling are not concentric and need to be adjusted. In this way, check the upper, lower, left and right four positions until they are all close and there is no gap. The requirements for different shaft degrees of the coupling are not more than 0.05mm

Axial clearance requirements of coupling

In order to avoid the collision between the two couplings during operation, the axial clearance between the two couplings should be kept uniform. The clearance can be checked by feeler gauge, generally 4-6mm.

No matter what, we have our own methods, just like we have our own learning methods when we study. Therefore, only by assembling the rolling bearing and coupling of the water ring vacuum pump according to the correct assembly method, can we better use them.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)