Vacuum pump for Photovoltaic (PV) production line

Dry screw vacuum pump in PV industry of application

PV

EVP is committed to the development and research of new energy to provide professional vacuum solutions for the photovoltaic industry. Etch, PECVD and Lamination — In EVP you will find high quality and high reliability vacuum systems.

PV cell production

From the fabrication of silicon crystals to the manufacture of solar cells to the layering of solar modules — these processes are impossible without a vacuum.Whether the focus is on crystallization or thin film coating is irrelevant – tailor-made vacuum solutions are a key factor in PV production.As solar panel production increases, this area of production is becoming increasingly important.EVP provides high quality products and outstanding solutions for this market.

Lamination

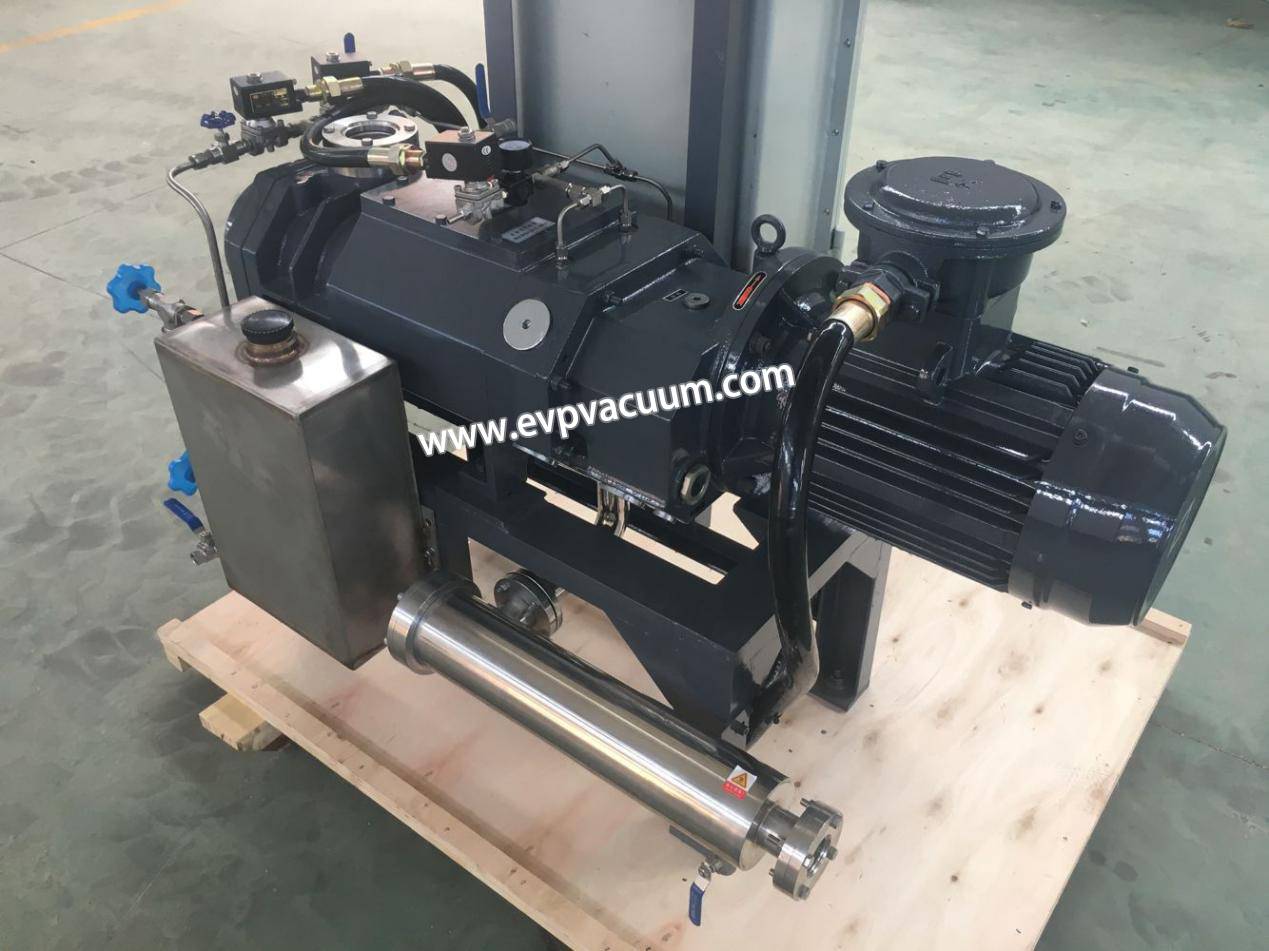

The solar cell lamination process consists of encapsulating the solar cell and connecting the front and rear protection plates.For best results, the screw vacuum pump provided by the EVP is perfect for this application.Dry Screw Vacuum Pump Performance Benefits: Optimized for handling by-products from laminating processes, high uptime and low maintenance costs, high vapor resistance and particle compatibility, easy field cleaning, low operating costs, minimal maintenance, extended service intervals.

What is the relationship between photovoltaic power generation and vacuum pumps?

Various processes of crystalline silicon, CdTe, CIGS, or silicon thin film technology are used to produce photovoltaic cells that capture sunlight and convert it to energy, which is closely related to the development of vacuum technology.From the pulsed silicon to the production of solar cells, to the lamination of solar cell modules, it is impossible to manufacture without a vacuum.Whether the focus is on crystallization or thin film coating, it doesn’t matter, providing a tailored vacuum solution is a key factor in PV production.

The solar cell lamination process involves packaging the solar cell while connecting the front and rear protection plates.For best results, dry screw vacuum pumps provide vacuum pumping speeds and are ideal for this application.

The membrane is a single layer of material that ranges in thickness from nanometers to a few microns.Thin-film technology has improved over the past few decades and requires reliable products to achieve optimal quality.For thin film deposition processes, high-performance dry screw vacuum pumps can be used to provide first-class vacuum equipment to meet the requirements of this application.

Dry screw vacuum pump of performance characteristics

1) Clean and environmental protection;

2) High vacuum degree;

3) Anticorrosion design (patented technology);

4) Can remove condensable gas and a small amount of dust gas (patent technology);

5) Special shaft seal design to prevent mutual contamination between the pumping medium and the lubrication system;

6) Anti-overload design;

7) Smooth operation;

8) High standard configuration;

9) The accessories are fully equipped

10) Quality and sound spare parts supply.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)