What is rotary vane vacuum pump

Rotary vane vacuum pump (Rotary vane pump) is an oil-sealed mechanical vacuum pump. Its working pressure ranges from 101 325 to 1.33 x 10-2 (Pa) and belongs to low vacuum pump. It can be used alone or as the front pump of other high vacuum pumps or ultra-high vacuum pumps. It has been widely used in metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, medicine and other production and scientific research departments.

Rotary vane vacuum pump can extract the dry gas from the sealed container, and a certain amount of condensable gas can also be extracted if a gas ballast device is attached. But it is not suitable for extracting gases with excessive oxygen, corrosive to metals, chemical reaction to pump oil and particulate dust.

Rotary vane vacuum pump is one of the most basic vacuum acquisition equipment in vacuum technology. Rotary vane pumps are mostly small and medium-sized pumps. There are two kinds of rotary vane vacuum pumps: single-stage pump and double-stage pump. The so-called two-stage structure is to connect two single-stage pumps in series. Generally, it is made into two stages to obtain higher vacuum. The relationship between the pumping speed and the inlet pressure of the rotary vane pump is as follows: under the inlet pressure of 133 3a, 1.33 Pa and 1.33 x 10-1 (Pa), the pumping speed of the rotary vane pump shall not be lower than 95%, 50% and 20% of the nominal pumping speed of the pump, respectively.

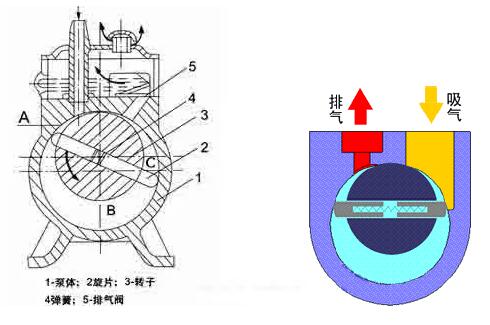

The diagram shows the working principle of the rotary vane pump. Rotary vane vacuum pump is mainly composed of pump body, rotor, rotary vane, end cover, spring and so on. A rotor is eccentrically installed in the cavity of the rotary vane pump. The outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between them). Two rotary vanes with springs are installed in the rotor groove. When rotating, centrifugal force and spring tension keep the top of the rotor in contact with the inner wall of the pump chamber. Rotor rotation drives the blade to slide along the inner wall of the pump chamber.

The two rotating vanes divide the crescent-shaped space enclosed by the rotor, pump chamber and two end caps into three parts: A, B and C, as shown in the figure. When the rotor rotates in the direction of arrow, the volume of space A connected with the suction port increases gradually and is in the process of suction. The volume of space C connected with the exhaust port is gradually reduced and is in the process of exhaust. The volume of space B in the middle is also gradually decreasing and is in the process of compression. Because the volume of space A increases gradually (i.e. expands), the pressure of gas decreases, and the pressure of gas outside the inlet of the pump is stronger than that inside space A, the gas is inhaled. When space A is isolated from the suction port, that is to say, when it moves to space B, the gas begins to be compressed, the volume gradually reduces, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas is discharged into the atmosphere through the oil layer in the tank. Continuous operation of the pump achieves the purpose of continuous pumping. If the exhausted gas passes through the airway and transfers to another stage (low vacuum stage), it is pumped out by the low vacuum stage, and then compressed by the low vacuum stage and discharged into the atmosphere, a two-stage pump is formed. At this time, the total compression ratio is borne by two stages, thus increasing the ultimate vacuum.

Rotary vane vacuum pump is one of the most basic vacuum acquisition equipment in vacuum technology, but it also has some shortcomings. One of them is that inconvenient start-up causes a lot of fuel injection.

Our company has recently developed a “fourth generation” rotary vane vacuum pump, which greatly reduces the phenomenon of fuel injection.

rotary vane vacuum pump installation instructions

1. Pumps should be installed in strong ground areas, and there should be sufficient room around them for inspection, maintenance and maintenance.

2. The foundation level should be maintained under the pump base. It is suggested to install cushion rubber or bolt at the four corners of the base to ensure smooth operation and small vibration of the pump.

3. The connecting pipeline between the pump and the system should be sealed reliably. Oil-resistant rubber can be used to connect the sealing gasket with the metal pipeline for the small pump, and vacuum rubber tube can be used for the small pump. The diameter of the pipeline should not be less than the pump suction port, and the pipeline should be short and less elbows.

Common Faults of Rotary Vacuum Pump and Their Elimination

1. The pump does not turn. If the condition is unknown, the pump should not be turned on in order to avoid aggravating the fault. Hand can and can’t move.

A) The pump can be turned without turning. Causes can cause coupling failure; belt slippage; motor wiring error; motor damage; power outage and so on.

B) Can not be discharged or coiled up very heavy, the reason may be because the starting pump temperature is too low, the pump oil viscosity is too high; the design and manufacturing reasons for the shutdown of the pump return too much oil. Too much oil is returned from the shutdown caused by too high oil level (too much oil, or condensation of water vapor in the pump, or condensation in the exhaust pipe); there are foreign bodies in the pump (welding slag in the intake pipe, oxide, screw spring and other pump parts debris); the screw deformed and stuck; occlusion occurred (copper sleeve, rotor, middle wall, pump cover, stator, bearing).

2. Pump temperature is too high. The highest oil temperature measured near the lower exhaust valve exceeds the specified value in the instruction. As the pump temperature increases, the viscosity of the pump oil decreases greatly, and the saturated vapor pressure of the pump oil increases, the limit pressure of the pump increases and the pumping efficiency decreases; the rubber parts are easy to aging; and the thermal expansion makes the operation reliable. The reasons for the high pump temperature may be that the ambient temperature of the pump is too high, the intake temperature is too high, the intake cooling device is invalid, the medium pressure of the pump is too high for long-term continuous operation, the cooling water quantity of the water-cooled pump is insufficient, the design effect of the circulating water is not good, the temperature control water regulating valve is invalid, etc.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)