what’s the liquid ring vacuum pump

what’s the liquid ring vacuum pump

Liquid ring vacuum pump is a crude pumping pump using liquid as working medium. Water ring vacuum pump uses water as working medium. Oil, sulfuric acid and acetic acid can also be used as working medium. Industrial water ring vacuum pump is mostly used.

Liquid ring vacuum pump is divided into single-stage liquid ring vacuum pump and double-stage liquid ring vacuum pump, and the difference between single-stage and double-stage functions. The single-stage liquid ring vacuum pump and the double-stage liquid ring vacuum pump refer to the stages of their impellers; the single / double action refers to the form of their impellers / casings, and the gas of the impeller of the single-acting impeller vacuum pump experiences one suction / discharge in one revolution; the gas of the impeller of the double-acting vacuum pump experiences two suction and discharge in one revolution.

Liquid ring vacuum pump structure:

Liquid ring vacuum pump consists of pump cover, pump body, disc, impeller, mechanical seal, motor and other parts. The intake pipe and exhaust pipe are connected with the pump cavity through the suction hole and exhaust hole on the disk installed on the pump cover. The shaft is installed in the pump body eccentrically. The impeller is fixed on the shaft with a flat key. The gap between the two end faces of the pump is adjusted by the pad between the pump body and the disk. The gap between the impeller and the disk on the pump cover is adjusted by the pad between the disk and the pump body. The gap between the two end faces of the impeller and the disk on the pump cover is adjusted by the pad between the two end faces of the pump and the disk on the pump cover The gap determines the loss of gas in the flow from the air inlet to the exhaust port and the limit pressure.

The seal of vacuum pump adopts mechanical seal, which is installed between impeller and pump body. The clearance between impeller and pump body is determined by mechanical seal.

A disc is installed on the cover of the vacuum pump. The disc is equipped with suction and exhaust holes and flexible exhaust valve plates. The function of the flexible valve plate is to discharge the gas before the exhaust port when the gas pressure between the impeller blades reaches the exhaust pressure, so as to reduce the power consumption due to the excessive gas pressure.

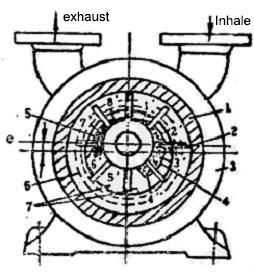

Liquid ring vacuum pump working principle:

As shown in the figure: a proper amount of water is filled in the vacuum pump body as the working fluid. When the impeller rotates clockwise as shown in the figure, the water is thrown around by the impeller. Due to the centrifugal force, the water forms a closed ring of approximately equal thickness, which is determined by the shape of the pump cavity. The inner surface of the lower part of the water ring is just tangent to the impeller hub, and the inner surface of the upper part of the water ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the water ring). At this time, a crescent space is formed between the impeller hub and the water ring, and this space is divided into several small cavities equal to the number of blades by the impeller. If the starting point is 0 ° at the lower part of the impeller, the volume of the small cavity will increase from small to large when the impeller is 180 ° before rotation, and the small cavity is connected with the suction port on the end face, at this time, the gas will be inhaled, and the small cavity will be isolated with the suction port when the suction is finished; when the impeller continues to rotate, the small cavity will change from large to small, so that the gas will be compressed; when the small cavity is connected with the exhaust port, the gas will be discharged out of the vacuum pump.

liquid ring vacuum pump precautions

When selecting liquid ring vacuum pump, the following matters shall be noted:

1. The working pressure of liquid ring vacuum pump shall meet the requirements of the limit vacuum and working pressure of vacuum equipment. For example, vacuum coating requires a vacuum degree of 1 × 10-5mmhg, and the vacuum degree of the selected vacuum pump shall be at least 5 × 10-6mmhg. Generally, the vacuum degree of the pump is half to one order of magnitude higher than that of the vacuum equipment.

2. Select the working point of vacuum pump correctly. Each kind of pump has a certain working pressure range, for example: the diffusion pump is 10-3 ~ 10-7mmhg. In such a wide pressure range, the pumping speed of the pump changes with the pressure, and its stable working pressure range is 5 × 10-4 ~ 5 × 10-6mmhg. Therefore, the working point of the pump should be selected within this range, and it cannot be allowed to work for a long time under 10-8mmhg. Another example is that titanium sublimation pump can work at 10-2mmhg, but its working pressure should be less than 1 × 10-5mmhg.

3. Under its working pressure, the liquid ring vacuum pump shall be able to discharge all gas produced in the process of vacuum equipment.

4. Correctly combine the vacuum pump. Because of the selective pumping of vacuum pump, sometimes selecting one pump can not meet the pumping requirements. Several pumps need to be combined to supplement each other to meet the pumping requirements. For example, the titanium sublimation pump has a very high pumping speed for hydrogen, but it can’t pump helium, while the three pole sputtering ion pump (or the two pole asymmetrical cathode sputtering ion pump) has a certain pumping speed for argon, and the combination of the two will make the vacuum device get a better vacuum degree. In addition, some vacuum pumps can’t work under atmospheric pressure and need pre vacuum; some vacuum pumps need pre stage pumps because the outlet pressure is lower than atmospheric pressure, so they need to be combined for use.

5. Requirements of vacuum equipment for oil pollution. If the equipment is strictly oil-free, various oil pumps should be selected, such as: water ring pump, molecular sieve adsorption pump, sputtering ion pump, low temperature pump, etc. If the requirements are not strict, oil pump can be selected, and some anti oil pollution measures, such as cold trap, baffle, oil trap, etc., can also meet the requirements of clean vacuum.

6. Understand the composition of the extracted gas. The gas contains no condensable vapor, whether there is particle dust, whether there is corrosiveness, etc. When selecting a vacuum pump, it is necessary to know the gas composition and select the corresponding pump for the extracted gas. If the gas contains steam, particles and corrosive gas, auxiliary equipment, such as condenser, dust remover, etc., shall be installed on the air inlet pipeline of the pump.

7. How does the oil vapor discharged from the liquid ring vacuum pump affect the environment. If the environment is not allowed to be polluted, the oil-free vacuum pump can be selected, or the oil vapor can be discharged to the outdoor.

8. Whether the vibration produced during the operation of liquid ring vacuum pump affects the process and environment. If the process is not allowed, the pump without vibration shall be selected or anti vibration measures shall be taken.

9.Price, operation and maintenance cost of liquid ring vacuum pump.

liquid ring vacuum pump selection

Liquid ring vacuum pump type

The type of liquid ring vacuum pump is mainly determined by the air volume, vacuum degree or exhaust pressure required for operation.

When the liquid ring vacuum pump works, the following two aspects should be paid attention to:

1. As far as possible, it is required to operate in the high efficiency area, that is, the area with critical vacuum degree or critical exhaust pressure.

2. Avoid operation near the maximum vacuum or exhaust pressure. In this area, not only the efficiency is very low, but also the work is very unstable, easy to produce vibration and noise. For vacuum pumps with high vacuum degree, cavitation often occurs when they operate in this area. The obvious sign of this phenomenon is that there is noise and vibration in the pump. Cavitation will cause damage to pump body, impeller and other parts, so that the pump can not work.

According to the above principles, when the vacuum degree or gas pressure required by the vacuum pump is not high, it can be selected preferentially in the single-stage vacuum pump. If the vacuum degree or exhaust pressure is high, the single-stage vacuum pump is often unable to meet the requirements, or the pump is required to have a large amount of gas under the condition of high vacuum degree, that is, the performance curve is required to be relatively flat under the condition of high vacuum degree, so the two-stage vacuum pump can be selected. If the vacuum degree is required to be more than – 710mmhg, water ring atmospheric pump or water ring roots vacuum unit can be selected as the vacuum pumping device.

If it is only used for vacuum pump, it is better to choose single acting vacuum pump. Because the single acting vacuum pump is simple in structure, easy to manufacture and maintain, and has good cavitation resistance under high vacuum.

If it is only used for compressor with larger air volume, it is suitable to select double acting vacuum pump. Because the double acting vacuum pump has large air volume, small volume and light weight, the radial force can be automatically balanced, the shaft is not easy to produce fatigue fracture, and the service life of the vacuum pump is long.

liquid ring vacuum pump select

After the type of liquid ring vacuum pump is preliminarily selected, the model of liquid ring vacuum pump shall be selected according to the air volume required by the system.

Failure and maintenance of liquid ring vacuum pump

Bearing position wear

Wear of transmission parts of liquid ring vacuum pump is a common problem, including bearing position, bearing seat, bearing chamber, keyway and thread. Traditional methods are mainly repair welding and brush plating spraying, but both of them have some disadvantages: the heat stress caused by high temperature of repair welding can not be completely eliminated, which is easy to cause material damage, leading to bending or fracture of parts; while brush plating is subject to coating thickness Limit, easy to peel, and the above two methods are metal repair metal, can not change the “hard to hard” fit relationship, under the combined effect of various forces, will still cause re wear. In modern western countries, polymer composite materials are often used to repair the above problems, while the United States and Jiahua technology system are widely used, which has strong adhesion, excellent compressive strength and other comprehensive properties. It can be repaired with polymer material, which is free of disassembly and machining. There is no influence of repair welding thermal stress, and the repair thickness is not limited. At the same time, the metal material of the product does not have the concession, which can absorb the impact vibration of the equipment, avoid the possibility of re abrasion, and greatly extend the service life of the equipment components, save a lot of downtime for the enterprise, and create huge economic value.

Erosion repair

The corrosion forms of liquid ring vacuum pump can be divided into two categories: overall (uniform) corrosion and local corrosion. The former occurs uniformly on all surfaces of vacuum pump, while the latter only occurs locally, such as hole corrosion, crevice corrosion, intergranular corrosion and stress corrosion. It is one of the effective anti-corrosion measures to apply organic coating on the surface of vacuum pump by using polymer composite material. It has good chemical resistance, excellent mechanical properties and adhesive properties. Compared with traditional pressure vessel welding and repairing, it has the characteristics of simple construction, low cost, safety performance and good repairing effect.

Crack repair

The liquid ring vacuum pump often cracks or breaks because of casting and processing defects, internal stress and overload operation. The conventional repair method is welding, but some parts are made of cast iron, aluminum alloy and titanium alloy, which is difficult to be welded. There are also some dangerous occasions prone to explosion, and it is more difficult to adopt welding repair method. Meijiahua technology is a “cold welding” technology, which can avoid thermal stress deformation, at the same time, the material has good adhesion, compression resistance, corrosion resistance and other comprehensive properties, and can meet the use requirements of various equipment components to the maximum extent, so as to effectively ensure production with the lowest cost input. Safe, convenient and reliable.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)