Why should the water ring pump be used together with Air ejector pump?

Water ring vacuum pump with Air ejector vacuum unit

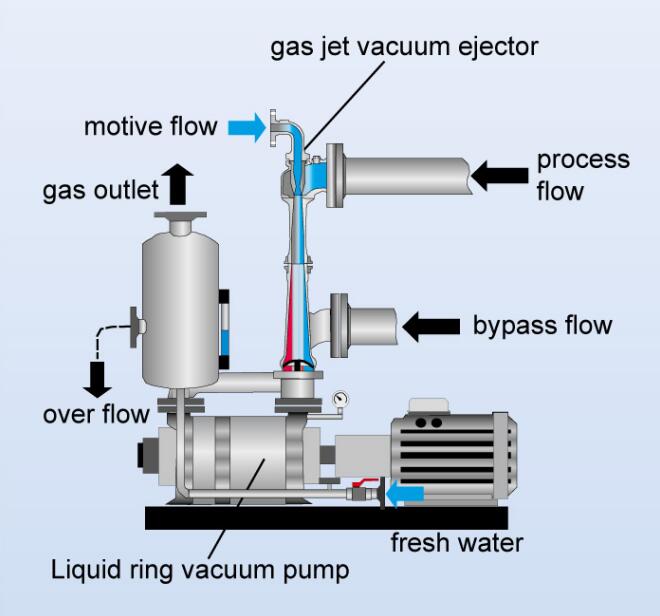

For water ring pumps, even if a two-stage pump is used, the increase in ultimate vacuum is only within a certain range, because it is limited by water saturation and vapor pressure. In order to improve the ultimate vacuum of the backing pump, it can be used in combination with an Air ejector pump. The editor uses the following information to explain this knowledge in detail:

The air jet pump is a pre ejector on the inlet pipe of the water ring vacuum pump. The opening of one end of the air jet pump is toward the atmosphere. By using the air jet generated by the pressure difference between the negative pressure of the vacuum pump and the atmospheric pressure, the lower suction pressure can be obtained in the air jet pump than that of the vacuum pump, so as to eliminate the limitation of the “limit suction pressure” of the vacuum pump on the improvement of the condenser pressure.

The suction area is in the limit vacuum state, the local vaporized water will rotate with the impeller, the pressure will rise and the bubble will burst, the local cavitation will occur on the surface of the impeller, and the operation noise is very large. Under long-term cavitation, the impeller of vacuum pump is easy to be damaged. After the water ring pump is equipped with an atmospheric ejector, the air flow of the pump is greatly increased, and the pressure in the suction area of the vacuum pump is much higher than the “limit suction pressure” corresponding to the water ring temperature, so there will be no “cavitation” phenomenon.

I believe you will understand the reason of using water ring pump air ejector unit after reading the content in this article; Water ring pump air ejector unit can effectively reduce the limit pressure of the pump, and the pumping speed will increase under the condition of lower pressure. Without cavitation, the operation of the vacuum pump will be more stable.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)