A New Frontier in Green Technology: Liquid Ring Vacuum Pumps Become a Key Enabler for Ocean Carbon Capture (DOC)

–Their corrosion resistance and moisture handling capabilities perfectly match the demanding process requirements of extracting carbon dioxide from seawater.

As global climate change continues to intensify, direct ocean capture (DOC), an innovative technology for extracting carbon dioxide directly from seawater, alongside direct air capture (DAC), is rapidly gaining attention among scientists and engineers. In this disruptive process, liquid ring vacuum pumps and units, leveraging their unique technological advantages, play an indispensable and core role, providing reliable power for large-scale, efficient, carbon-negative solutions.

I.DOC Technology Process Overview: Leveraging the Power of the Ocean

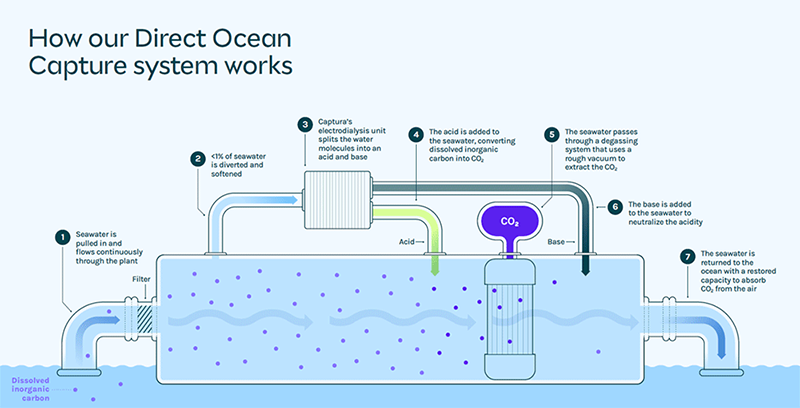

The basic principle of direct ocean capture (DOC) is to utilize the ocean as a vast natural carbon sink. Seawater absorbs approximately 30% of atmospheric carbon dioxide, with a concentration over 150 times that of air. DOC technology captures CO₂ by processing seawater, eliminating the need to process large volumes of air, theoretically resulting in higher efficiency. The typical process flow is as follows:

1.Acidification & Stripping: First, seawater is introduced into a contact tower. Here, a small amount of acid (such as sulfuric acid) is added to neutralize the seawater’s alkalinity and convert dissolved inorganic carbon (primarily in the form of bicarbonate ions (HCO₃⁻)) into free carbon dioxide gas.

2.Vacuum Stripping: This is the stage where liquid ring pumps play a key role. The acidified seawater is fed into a vacuum stripping tower (or degassing tower). Within the tower, a negative pressure well below atmospheric pressure is maintained. According to Henry’s law, the reduced partial pressure causes the CO₂ gas dissolved in the water to escape rapidly.

3.Gas Collection and Purification:The mixture of CO₂-rich gas and water vapor escaping from the top of the stripping tower is extracted by a vacuum pump. This mixture then undergoes condensation, compression, and purification to produce highly concentrated carbon dioxide suitable for storage or utilization.

4.Seawater Re–injection: After CO₂ removal and neutralization, seawater can be safely reinjected into the ocean. This seawater, with its reduced alkalinity, is even more capable of absorbing atmospheric CO₂.

(Image from Mitsui O.S.K. Lines, Ltd)

II.Selection of vacuum pump: Why liquid ringvacuumpump and vacuum system?

1.In the vacuum desorption process of DOC process, the pumping medium is a mixed gas with strong corrosiveness, high humidity, and may contain acidic aerosols. This harsh environment poses severe challenges to vacuum equipment:

*Corrosiveness: Acidic additives and seawater components require equipment materials with extremely high corrosion resistance.

*Wet gas handling: The medium is in a saturated wet gas state. Many dry vacuum pumps are prone to liquid hammer, corrosion or performance degradation when handling such media.

*Reliability: As a continuously running industrial device, it requires extremely high operating stability and low maintenance costs.

2.The technical characteristics of liquid ring pumps make it an ideal choice for DOC applications

(1) Innate corrosion resistance and material diversity: Liquid ring pumps can use corrosion-resistant liquids (such as fresh water, low-carbon stainless steel pump body with specific working fluid) as sealing liquids. The sealing liquid is in direct contact with the pumped gas, which can effectively wash, cool and neutralize the acidic gas and protect the pump body from corrosion. In addition, the material of the liquid ring pump is relatively comprehensive. CI, SS304, SS316L, and even duplex steel and super duplex steel can be selected according to the working conditions.

(2) Efficient handling of condensable vapor: The liquid ring pump performs well in pumping saturated wet gas or condensable vapor. The water vapor will be quickly condensed and carried away by the working fluid in the pump chamber, which will not damage the operation of the pump and will improve the pumping efficiency.

(3) Excellent reliability: The liquid ring pump has a simple structure, low speed, and only one mechanical contact point (impeller), which means a lower failure rate and longer service life. It is very suitable for DOC plants that need to operate continuously 24/7.

(4) Isothermal compression: The compression process of the liquid ring pump is close to isothermal compression. It is very suitable for compressing media such as CO₂ that are easy to heat up and precipitate crystals during compression, avoiding operational problems caused by excessive temperature.

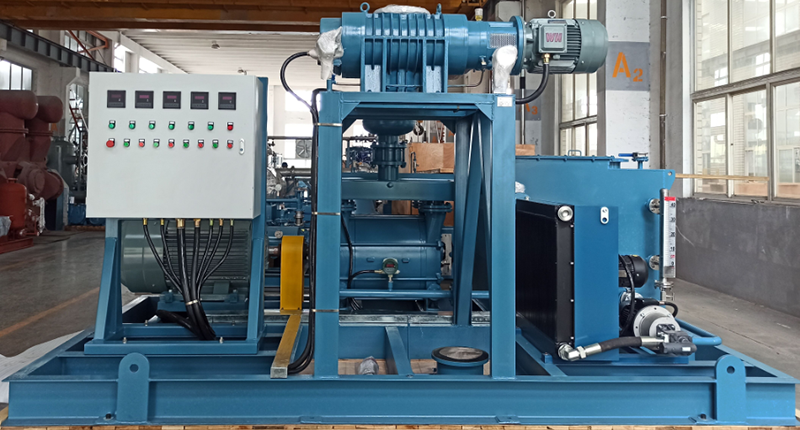

(Image from EVP actual shipment pictures)

III. The Role of Liquid Ring Vacuum Systems: Beyond a Single Pump

In large-scale DOC projects, a liquid ring vacuum system (LRV) is often used, rather than a single pump. This system is an integrated solution, including:

* Liquid ring vacuum pump: The core pumping unit.

* Gas-liquid separator: Separates the pumped gas and working fluid.

* Heat exchanger: Continuously cools the circulating working fluid to maintain optimal pump performance and vacuum levels.

* Control system: Fully automatically controls pump start/stop, liquid level, temperature, and pressure, ensuring optimal system operation.

This modular design improves energy efficiency, ensures more stable operation, and facilitates maintenance for the entire vacuum system.

(Image from EVP actual shipment pictures)

IV.Future Outlook

“DOC technology offers a highly promising new approach to addressing climate change.” With the construction and operation of the world’s first demonstration plants, liquid ring pumps, as the “unsung heroes” of the DOC ecosystem, are providing critical technical support for humanity’s ambitious goal of removing carbon dioxide from the atmosphere with their solid and reliable performance.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)