Principle and process of physical vapor deposition(PVD)

The need for high-performance thin-film coatings is higher today than ever, and many industries have turned to physical vapour deposition (PVD) as their coating method of choice. PVD is the gold standard for generating extremely thin, pure, and durable coatings from a wide array of target materials and substrates to coat everything from optics to computer chips.

I.What Is the PVD Coating Process?

PVD coating, also known as thin-film coating, uses a vacuum chamber to vaporise a solid material and deposit it onto a target substrate, atom by atom. The result is an extremely thin, extremely pure coating from a technique that is more environmentally friendly than many other coating technologies.

The PVD coating process occurs under vacuum conditions and consists of four main steps: ablation, transport, reaction, and deposition. This process deposits source atoms onto the surface of the substrate, leaving it coated with a strong, abrasion- and corrosion-resistant film.

1.Evaporation

The two main types of physical vapour deposition are Sputtering and Thermal Deposition.

2.Thermal evaporation deposition uses vacuum pressures and high temperatures to create the conditions necessary for the vaporisation of the target material.

Sputtering uses a high-vacuum chamber that dislodges atoms from the target using high-energy plasmas. These atoms are then ready for deposit onto the target surface, usually in a plasma arc.

This process biases the target before bombarding it with ionised gas in a vacuum environment. This ionic bombardment results in atoms “sputtering” off the target into a plasma cloud arc before transport and condensation.

Both processes have unique advantages and disadvantages that make them useful for different applications. Sputtering produces a highly uniform coating with low impurity rates, but it is also the slowest and most complex method. Thermal evaporation has higher throughput and high mineral utilisation efficiency but may require additional tools to achieve good uniformity during the process, such as sample rotation.

3.Transportation

The movement of vaporised atoms from the target material to the substrate requires precise timing and positioning. The correct PVD method for the material is important as well as the geometry of the system and deposition source in relation to the sample holder.

4.Reaction

PVD processes can use reactive or inert gases to produce a strong bond between the coating and the substrate for the best possible results. For example, oxygen and nitrogen are common gases used for reactive RF sputtering with metal oxides and nitrides.

5.Deposition

The final step of the process builds up the coating on the required substrate. Since the thin-film can be anywhere from a few atoms thick up to a few microns, a uniform deposition across the substrate is important. The PVD process involves rotating the substrate at a constant speed while monitoring the rate of deposition with other tools such as a quartz crystal microbalance.

Many industrial methodologies can automate the deposition process by putting a conveyor belt of targets in front of the vaporised arc for a certain length of time. Both sputtering and evaporation can use automation to speed up the PVD coating technique for mass production.

II.Advantages of PVD Coatings

1.Safer than Plating

PVD coating is an alternative to traditional metal coating processes, where a thin layer of metal coats a substrate. In industry, metal coating processes use either an electric current (electroplating) or an autocatalytic process (electroless plating) to achieve a strong bond between the substrate and metal. However, many traditional coating processes also produce potentially harmful waste products, and some processes such as cadmium coating are decreasing in popularity due to safety concerns.

PVD coating requires no compounds other than the substrate and target material, resulting in a more environmentally friendly, safe process that caters to a wide range of industries and applications.

2.Highly Durable

PVD coatings tend to have highly robust temperature tolerance and impact strength along with excellent abrasion and corrosion resistance.

3.Versatile

Unlike metal plating, PVD is suitable for almost any inorganic coating material over a massive range of substrates. Manufacturers can use different PVD technology to generate a wide range of finishes ideal for almost any application or part.

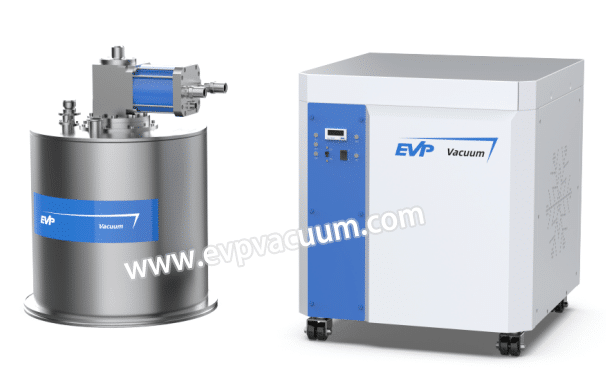

III. Vacuum pump used in PVD coating

1.Magnetically levitated molecular Pump

Magnetically levitated molecular pumps are commonly used in PVD equipment. Their ultimate pressure can reach 10^-8 Pa, making them suitable for ultra-high vacuum environments. Magnetically levitated molecular pumps compress and expel gas molecules through high-speed rotating turbine blades. They are clean and oil-free, making them commonly used in fields requiring high cleanliness, such as semiconductors and optics.

2.Cryopump

Cryopumps are high-vacuum pumps that typically operate below room temperature. They cool gas molecules using a cryogenic medium (such as liquid nitrogen), causing them to condense and be expelled at low temperatures. These pumps are suitable for PVD processes requiring extremely low temperatures, such as magnetron sputtering.

3.Other Auxiliary Pumps

Mechanical pumps (such as rotary vane vacuum pumps) are typically used as backing pumps, reducing the pressure to 10^-1 Pa before further vacuum is achieved using Magnetically levitated molecular pumps or cryopumps.

If you would like to learn more, please contact the EVP team. We would be happy to discuss the project with you and provide you with our vacuum equipment.