Advantages of Helium Mass Spectrometer Leak Detector for Detecting Leaks in Electronic Packaging Casings

The primary function of electronic packaging enclosures is to mount, secure, seal, and protect chips, as well as enhance their electrothermal performance. Electronic packaging enclosures play a crucial role in electronic devices, not only protecting chips from environmental damage but also improving the reliability and performance of electronic devices by enhancing electrothermal performance and facilitating overall assembly. Enclosures hold a significant position in terms of their impact on circuit reliability and their proportion of circuit cost. The requirements for sealing are extremely high; if the enclosure leaks, the entire chip will fail!

Electronic packaging enclosures require high levels of airtightness; therefore, helium mass spectrometry (HMS) leak detection is used for leak detection in electronic packaging enclosures. Helium mass spectrometry leak detection for electronic packaging enclosures offers the following advantages:

1.High sensitivity: Helium is a small molecule that diffuses rapidly and is accurately detected by the mass spectrometer, thus detecting even minute leaks.

2.High accuracy: As a detection device, the mass spectrometer possesses high precision and accuracy, accurately locating and determining the position and size of the leak.

3.Speed: Simple operation, fast detection speed, and rapid results, improving production efficiency.

4.Wide applicability: Applicable to various types of electronic device enclosures, helping to ensure product airtightness.

5.Non-destructive: Using helium as the detection gas does not damage the tested object, maintaining its integrity.

These advantages make helium mass spectrometry leak detection for electronic packaging enclosures a commonly used and effective leak detection method.

Electronic packaging materials include ceramics, glass, and metals. With the development needs of various electronics industries, packaging shells are widely used in aerospace, aviation, and communications fields.

Helium mass spectrometry leak detection uses helium gas to inspect for small leaks in the packaging shells of electronic components. Because helium atoms are very small, they can easily pass through small holes and enter the shell. Therefore, this detection method can detect very small holes (i.e., leaks with a leakage rate of approximately 10-11 to 10-13cm²/sec), and its sensitivity is comparable to radioactive leak detection methods, but it is simpler.

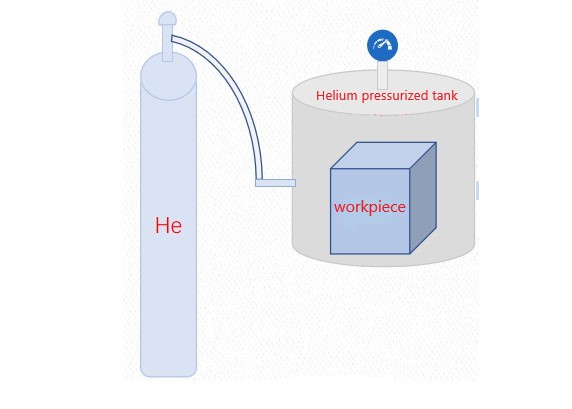

Taking a metal packaged device as an example, the back-pressure method for leak detection using a helium mass spectrometer requires a leak test to assess its seal. Due to the small size of the packaged device and the inability to evacuate or directly fill it with helium, EVP recommends using the “back-pressure method” with a helium mass spectrometer. The specific procedure is as follows:

1.Place the packaged device under test into a vacuum pressure chamber. Set the pressure and time according to the leak rate.

2.Remove the packaged device and purge the surface helium with air or nitrogen.

3.Place the packaged device into a vacuum leak detection chamber, connecting the chamber to the inlet of the helium mass spectrometer.

4.Start the helium mass spectrometer. In vacuum mode, set the leak rate to 5 × 10⁻¹⁰ Pa•m³/s for leak detection.

5.Analysis Results: Based on the detection results, determine if a leak exists, and identify its location and size.

This method is widely used in the electronics industry to ensure the sealing and stability of electronic components. For more information, please contact the EVP team!

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)