Air blower for gas analysis

Air blower introduction:

Air blast is mainly composed of the following six parts: motor, air filter, wind shell, air chamber, base (and oil tank) and drip nozzle. The blower operates by the eccentric rotor in the cylinder, and makes the volume change between the blades in the rotor slot to suck in, compress and spit out the air.

The conveying medium of blower is mainly clean air, clean gas, sulfur dioxide and other inert gases. It can also produce and transport other inflammable, explosive, corrosive, toxic and special gases on demand. So it can be widely used.

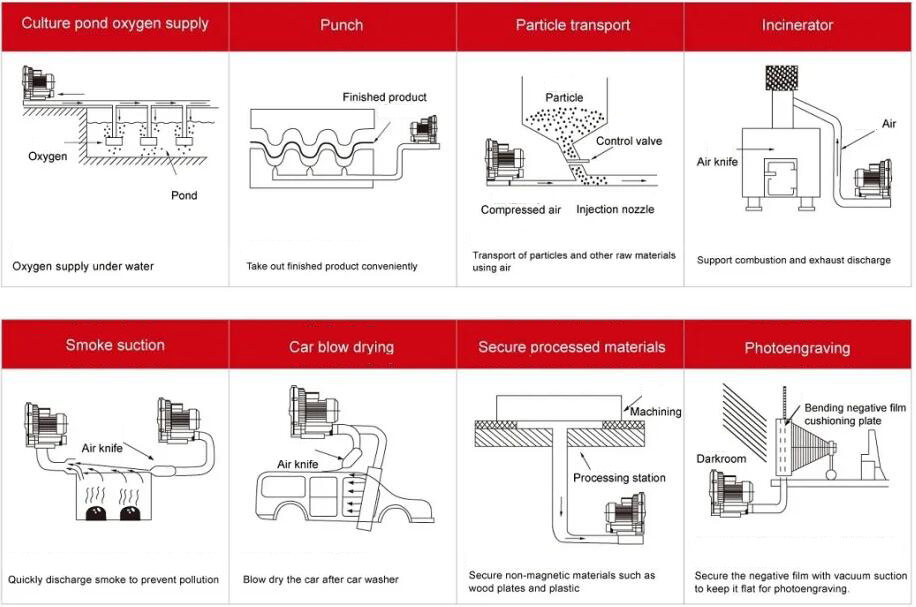

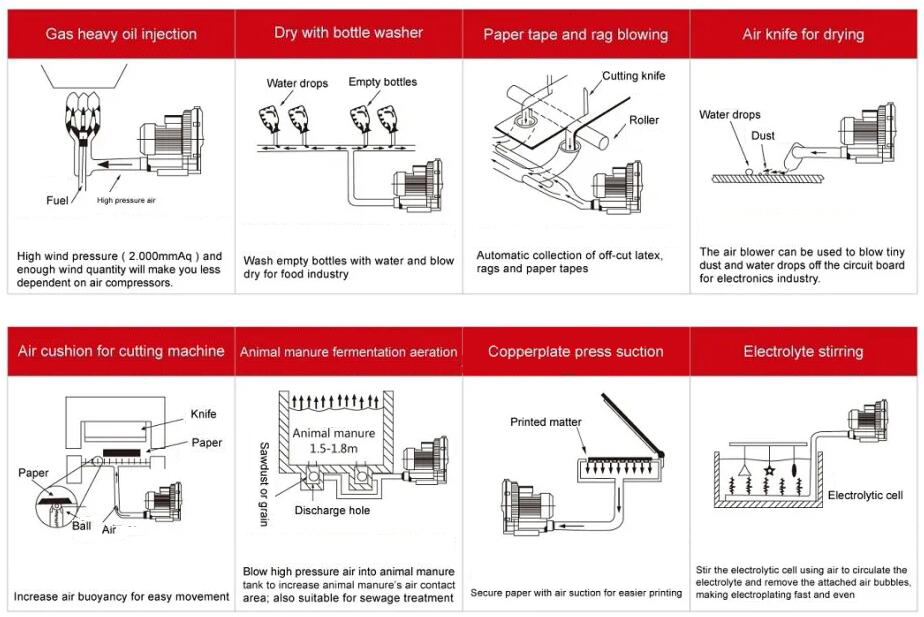

Product application

Accessories

Q & A tips:

Q: why should we add lubricating oil to air blast

Answer: air blast is through the centrifugal force generated by high-speed rotation to complete the intention, but in this process, only a little bit of sealing problems will affect the final application effect, and we often see that air blowing will add lubricating oil to the equipment when it is used, which must also be related to its sealing performance.

This idea is correct. If the lubricating grease is applied to the sealing packing and shaft seal of air blowing, the sealing effect can be very good, and the leakage of liquid can be prevented, and the dust can be avoided to play a two-layer maintenance effect.

But in fact, the starting point of adding lubricating oil to the air blast is far less than this. For example, the effect of lubricating oil will form an outstanding lubricating oil film, which can place the touch of external parts and reduce conflicts; in addition, it can also produce certain washing effect on the system of the equipment, and then some dust and dirt in between will be discharged to avoid causing problems.

In the end, the proper participation in the appropriate lubricating grease, air blowing must be more favorable.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)