air ejector structure and working principle

Air ejector is a kind of ejector which uses compressed air as working medium to pump and press gas (the extracted gas is called ejecting medium) to obtain vacuum. The compressed air enters the ejector and ejects supersonic airflow from the Laval nozzle. Due to the viscosity of the gas, the high-speed airflow absorbs the gas in the suction chamber, thus forming a vacuum in the suction chamber.

The air ejector has the following characteristics:

① The injector has no mechanical moving parts and is not restricted by lubrication and vibration. Therefore, its pumping capacity is very large.

② It has the advantages of simple structure, stable and reliable operation and long service life. As long as the structure and material of the ejector are selected properly, the gas containing a large amount of water vapor, dust, inflammable, explosive and corrosive gas can be well extracted.

③ There is no oil pollution in the system.

④ The working pressure range is wide, and vacuum with different pressure can be produced according to the need.

As a vacuum generator, air ejector is widely used in environmental sanitation, medicine, food processing, food packaging and other fields.

air ejector structure and working principle

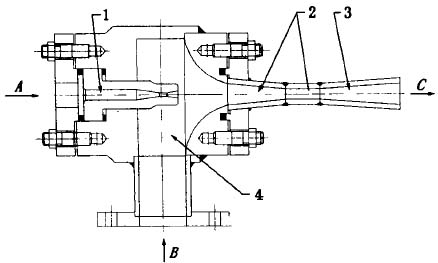

Fig. 1 Structure of atmospheric ejector

1. Laval nozzle 2. Mixing chamber 3. Diffuser 4. Suction chamber

A. Working medium inlet B. ejector medium inlet C. mixed gas outlet

It mainly consists of Laval nozzle, mixing chamber, diffuser and suction chamber. The Laval nozzle and diffuser constitute a special airflow duct with variable cross-section. The compressed air transforms the pressure energy into kinetic energy through the nozzle for air extraction, and the mixed air flow converts the kinetic energy into pressure energy through the diffuser for exhaust. The pressure difference between the inlet and outlet makes the air flow in the pipe.