Vacuum pump in Palm Oil Industry

What are the methods and techniques for refining palm kernel oil?

Wool palm kernel oil through refining, oil in the water content, impurities, acid value, peroxidation value can meet the national quality standards, and not easy to rancid deterioration, and favorable storage, crystal clear color, light flavor, cooking does not produce a lot of lampblack, maintain the flavor of oil.

There are three methods for refining crude palm kernel oil:

1. Mechanical method: including precipitation, filtration and centrifugal separation, mainly used to separate mechanical impurities suspended in grease and some colloidal impurities;

2, chemical method: mainly including acid refining, alkali refining, in addition, there are fat, oxidation, etc., acid refining is treated with acid, mainly to remove pigment, gel soluble impurities, alkali refining is treated with alkali, mainly to remove free fatty acid, oxidation is mainly used for decolorization.

3, physical and chemical methods: mainly including hydration, decolorization, steam distillation, hydration mainly remove phospholipid, decolorization mainly remove pigment, steam distillation used to remove odorous substances and free fatty acids.

Next, I will introduce the industrial vacuum pump used in palm kernel oil.

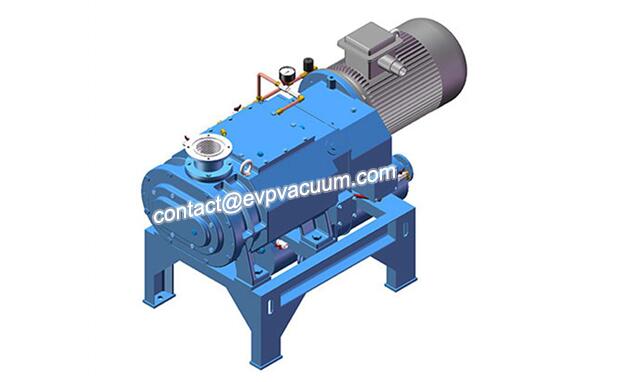

Screw pump range of use

Screw pump is the best choice for fuel pump, diesel pump, heavy oil delivery pump, lubricating oil pump, lubricating oil pump or chemical pump.

Screw pump can transport a variety of non-solid containing fluid medium or very high viscosity medium. They have a wide range of availability and high reliability, suitable for lubricated or non-lubricated media, corrosive media or gas-liquid mixtures.

Capacity: 0.5-1500m3 / h

Pressure: 0.1-2.0 Mpa

Viscosity: 0.5-100,00mm2 / s

Temperature: -30-200 ℃

Media: various lubricants and fuels

Structure: horizontal, vertical, portable structure, heating chamber

Safety: explosion proof, waterproof, safety valve, alarm sensor.

Screw pump field

1. Petrochemical industry: all kinds of lubricating oil, crude oil, residual oil, heavy oil, asphalt, diesel oil, gasoline, etc

Transfer pump.2. Shipbuilding industry: transfer pump, cargo pump, booster pump, splitter pump for all kinds of fuel oil, lubricating oil, waste oil, bilge sludge and sea water engine lubrication pump

3. Chemical industry: pumps for various acid, alkali, salt solutions, resins, glycerol, alkenes, polymers and various cosmetic emulsions.

4. Coating industry: used for all kinds of printing ink, paint, paint, paint, etc.

5. Food industry: used for all kinds of high viscosity medium pump, such as alcohol, beverage, honey, sugar juice, toothpaste, milk, soy sauce, animal oil, vegetables and chocolate, etc

. 6. Storage and transfer business: loading and unloading of cargo from oil stations, ships and tankers.

Screw pump features

1. The import and export civilization adopts special design to ensure enough medium left in the pump. Even if all the medium in the suction tube is discharged, the pump still has very good self-priming performance.

2, the pump body adopts a special structure of circular valve, open when the outlet pressure is higher than the working pressure. Then, some medium will return to the pump inlet or save through the circular valve. At the same time, the pump can be started at full pressure, greatly reducing torque.

3. Use synchronizer gear to transfer torque from active screw to idler screw to ensure no metal contact and power transfer between transfer elements. Therefore, the transmission element is highly reliable for any medium, and the pump can be protected from dry rotation damage in a short time.

4. When the pump works, the mesh screw forms a sealing civilization in the pump body. With the rotation movement of the screw, the liquid in the sealing civilization and the sealing civilization move axially and transfer to the pump outlet steadily. Constantly. Since the sealing capacity does not change in the working pump, there is no pulsation when pumping liquid.

5, screw pump body has a variety of different heating structure options, adapt to different temperatures of different media.

Additional information on screw pump

Our pump can be designed according to the special needs of customers: horizontal, vertical, car structure; Explosion-proof grade, protection grade, insulation grade (for work in hazardous areas), special requirements of special stainless steel (food industry, corrosive liquids, etc.), heating room, safety valve, alarm sensor, etc

Our pumps (mainly dual-screw pumps) and systems are ideal solutions for tanker terminals, oil production and processing. These include industrial, petrochemical, shipping and shipbuilding, and food and pharmaceutical industries. You can ask us for all relevant technical data, performance data, design, options, principles, application advantages, and last but not least the application field of the corresponding pump.