Application of Liquid Ring Pumps in Vacuum Filtration/Compression Filtration

Liquid ring pumps play a key role in vacuum filtration and compression filtration. Their core advantages lie in their strong resistance to contamination and their ability to handle moisture and corrosive gases. They are particularly suitable for filtration processes where liquids or particles are easily generated. The following is an analysis of specific applications:

I. Application in Vacuum Filtration (Evacuation)

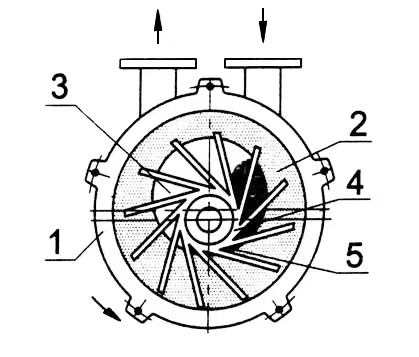

1. Working Principle

A liquid ring pump forms a liquid ring through the eccentric rotation of its impeller. This pump draws air/gas from the suction side, creating a vacuum. This pressure differential forces the filtrate through the filter medium (such as filter cloth or membrane). The vacuum range is typically -0.09 to -0.095 MPa (10 to 30 kPa absolute pressure), meeting most filtration requirements.

2. Typical Applications

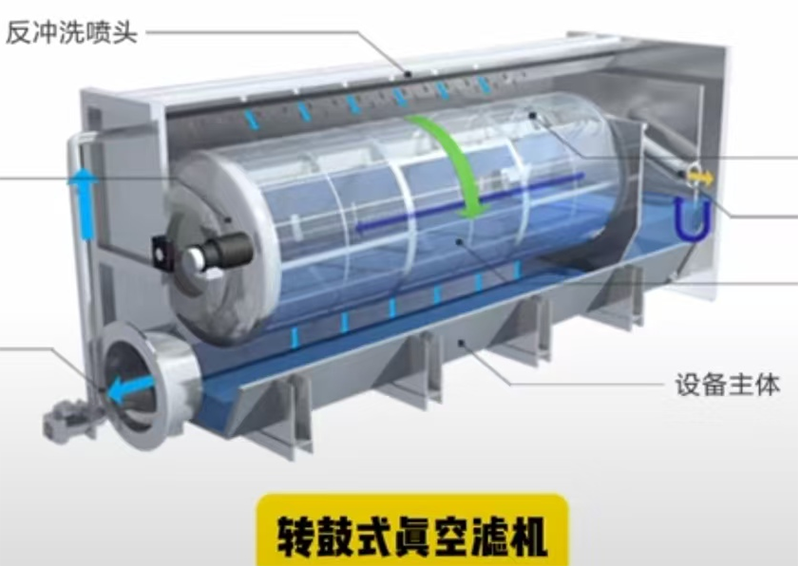

Rotary Drum Vacuum Filters: A liquid ring pump extracts air from the drum, creating a negative pressure to filter the slurry.

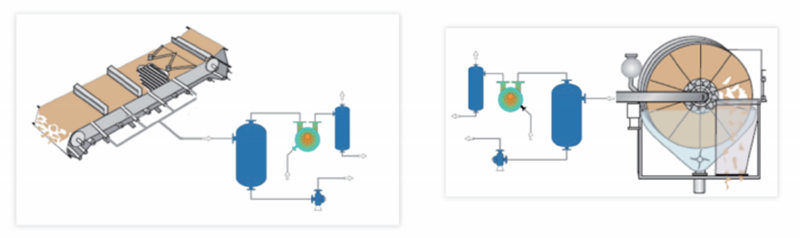

Belt Vacuum Filters: A vacuum zone is maintained beneath the filter belt, enabling continuous liquid removal.

Ceramic Vacuum Filters: Process high-solids materials such as mine tailings.

3. Technical Advantages

Anti-clogging: Can absorb small amounts of filtrate or particles without damage from liquid ingress.

Stable Operation: The water ring seal isolates the gas from the pump body, reducing the risk of corrosion (especially suitable for acidic and alkaline filtrates).

Energy-saving Solution: Combined with a gas-water separator and a circulating water tank, this achieves closed-loop utilization of the working fluid.

II. Applications in Compression Filtration (Gas Booster)

1. Working Principle

The liquid ring pump compresses gas on the exhaust side, with an output pressure of up to 0.1-0.3 MPa (gauge). It is used for:

Dehumidifying filter cakes (e.g., dehydration by pressing)

Pneumatic conveying of dry filter cakes

2. Typical Applications

Filter Press: Compressed air assists in cake extrusion (e.g., membrane filter presses).

Gas Backflush Cleaning: Compressed air pulses clean the filter element/bag.

3. Unique Values

Gas-Liquid Mixed Transport Capability: Can directly compress liquid-containing gases without pre-drying.

Oil-Free Compression: The working medium is water or solvent, avoiding oil contamination (preferred for the food and pharmaceutical industries).

III. System Design Key Points

1. Selection Parameters

| Parameters | Recommended Vacuum Filtration Values | Recommended Compression Filtration Values |

|———–|———————-|———————-|

| Vacuum Degree | -0.092 MPa and above | – |

| Exhaust Pressure| – | ≥0.15 MPa |

| Gas Volume | Calculated by filter area x pumping speed | Calculated by gas consumption per pressing cycle |

| Working Fluid | Water or antifreeze | Water or process solvent |

2. Additional Configurations

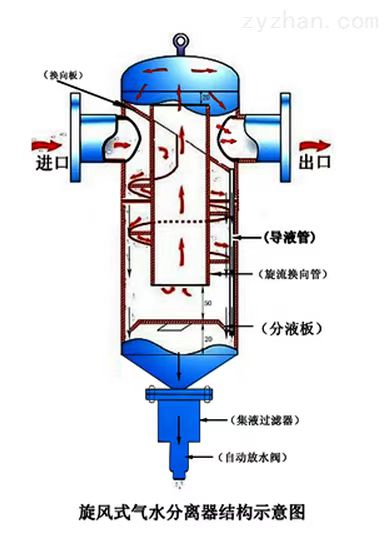

Steam Separator: Recovers the working fluid and exhausts gases (vacuum side).

Heat Exchanger: Controls the working fluid temperature (maintains optimal viscosity).

Corrosion Protection Options: Pump body materials include SS316L and titanium alloy (resistance to acid and alkali conditions).

3. Energy-Saving Techniques

Variable Frequency Control: Adjusts the speed based on the filtration stage (e.g., high speed during pre-pumping, low speed during pressure holding).

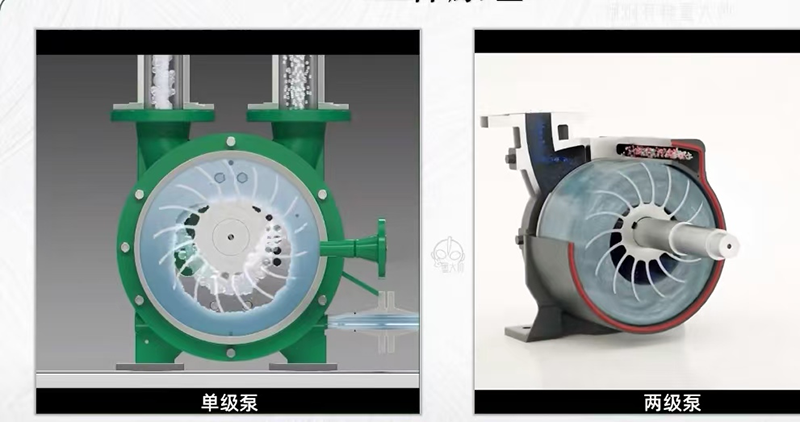

Multi-Stage Series: Two-stage liquid ring pumps can achieve higher vacuums (-98 kPa).

IV. Solutions to Common Problems

| Symptom | Cause | Countermeasures |

|—————-|———————|————–|

| Insufficient vacuum | Excessive working fluid temperature | Install a cooler or add water to reduce temperature |

| Water in exhaust gas | High separator liquid level | Adjust the automatic drain valve threshold |

| Sudden increase in power consumption | Impeller scaling or wear | Regularly pickle/replace the impeller |

| Abnormal noise | Cavitation (excessive vacuum) | Reduce speed or increase working fluid flow|

V. Industry Application Cases

1. Mining:

Copper concentrate vacuum filtration (50 m2 rotary drum filter + 55 kW liquid ring pump), filter cake moisture content reduced from 35% to 12%.

2. Chemical Industry:

Titanium dioxide filter press compression (0.2 MPa pneumatic push), production capacity increased by 30%.

3. Environmental Protection:

Sludge dewatering (liquid ring pump dual-function vacuum + compression), replacing traditional Roots pump + screw unit.

VI. Comparison with Other Vacuum/Compression Equipment

| Equipment Type | Advantages of Liquid Ring Pumps | Limitations |

|—————-|———————————-|———————|

| Roots Pump | More resistant to liquid impact | Lower ultimate vacuum |

| Rotary Vane Pump | Low maintenance cost, can discharge liquids directly | Not suitable for high-dust environments |

| Screw Compressor | Can be wet-compressed, no oil contamination | Low single-stage pressure ratio (≤3:1) |

Conclusion: For filtration applications involving liquids, particles, or corrosive media, liquid ring pumps are the preferred solution, balancing reliability, cost-effectiveness, and adaptability.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)