Difference between CF, KF, and ISO Flanges

Flange connections are widely used in the connection of vacuum units, such as vacuum pumps and pipes, valves, cold traps. Commonly, there are three types of them: CF, KF and ISO. What are differences between them?

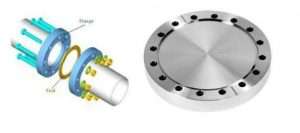

1.CF flange:

CF is the abbreviation for Conflat Flange. It is a static metal seal. Sealing material is usually Viton, PTFE, and oxygen-free copper. Flange material is generally SS304, SS316, etc. It can withstand high temperature baking, and the applicable vacuum degree is up to 10-12 mbar, common calibers include: DN16, 40, 63, 100, 160, 200, 250, etc.

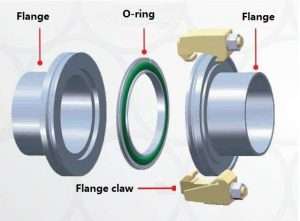

2.KF flange:

KF is a quick-release flange, easy to disassemble, the main components are: flange, seal ring, centering bracket, clamp. Seal material is usually Viton, Buna, Silicone, EPDM, aluminum, etc. Flange material is generally SS304, SS316, etc., and can withstand high temperature baking, the applicable vacuum degree up to 10-8 mbar, common caliber includes: DN 10, 16, 25, 40, 50, etc.

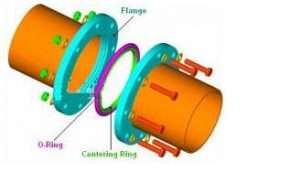

3.ISO flange (can be subdivided into ISO-K and ISO-F):

The sealing material is usually Viton, Buna, Silicone, EPDM, aluminum wire, etc. The flange material is generally SS304, SS316, etc. If using fluorine rubber O-rings, it can withstand 150 °C baking. Applicable vacuum levels up to 10-8 mbar, common calibers include: DN 63, 100, 160, 200, 250, 320, 400, 500 and 630. ISO flanges and tubing can be used in a wide range of applications, from atmospheric pressure to high vacuum, often for assembly and disassembly. The diameter of a typical pipe is more than 50mm (2 inches). Two commonly used ISO flanges are ISO-K and ISO-F

a. ISO-K vacuum fittings usually consist of a flange, a clamp, an O-Ring, and a centering ring. See below picture for your reference.

b. ISO-F vacuum fittings usually consist of a flange, an O-Ring, and a centering ring. Unlike ISO-K, flanges are sturdy with bolts. See below picture for your reference.

Tag: Vacuum unit,Flange

Edited by: Emily Fu ( Shanghai EVP Vacuum Technology Co., Ltd. )

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)