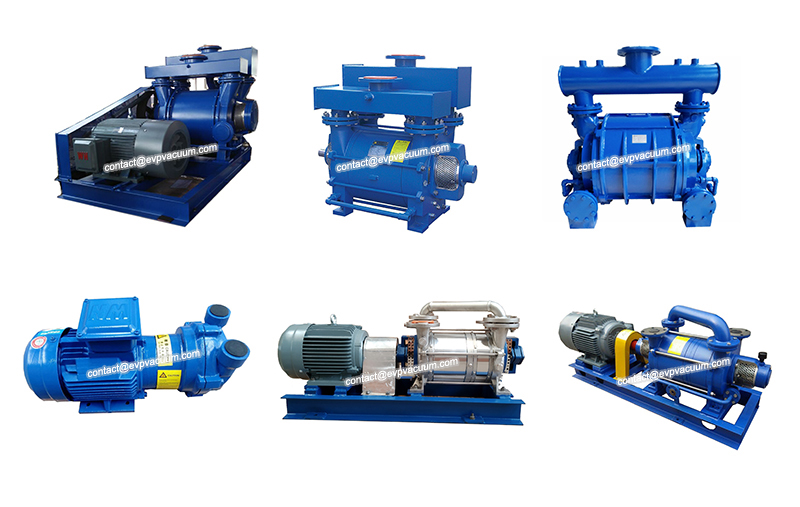

best water ring vacuum pump selection

The best type of water ring vacuum pump should be selected according to the air volume required by the system. Besides the important relationship between the working parameters of the water ring vacuum pump and its design and production process, the use environment and requirements of the water ring vacuum pump also seriously affect the actual performance of the water ring vacuum pump. Let’s learn about the best selection method of water ring vacuum pump in detail.

Best water ring vacuum pump selection table

| Model | main features | Ultimate vacuum mmHg | Working vacuum mmHg | Pumping speed range m3/min |

Sealing form |

| SK | Domestic design of single-stage water ring vacuum pump, simple structure, easy maintenance.

At present, the main domestic low vacuum water ring vacuum pump. |

-700 | -300~-650 | 0.15~120 | Packing, mechanical seal |

| 2SK | The domestic design of two-stage water ring vacuum pump is equivalent to the use of two SK water ring pumps in series,

Compared with single-stage water ring pump, 2SK has the characteristics of high vacuum degree and high pumping speed under high vacuum. At present, the main water ring vacuum pump in China. |

-735 | -300~-700 | 1.5~30 | Packing, mechanical seal |

| 2BV | Siemens advanced technology, coaxial pump, compact structure, high efficiency, high vacuum, stable performance,

It will gradually replace SK and 2SK series 0.4 ~ 6m3/min water ring vacuum pump. |

-735 | -300~-700 | 0.45~8.33 | mechanical seal |

| 2BE1 | Siemens advanced technology, high efficiency, high vacuum, stable performance,

It will gradually replace SK and 2SK Series 6 ~ 120m / min water ring vacuum pumps. |

-735 -640 |

-300~-700 -300~-600 |

5~400 | Packing, mechanical seal |

1、 Vacuum degree required by the process

The working pressure of vacuum pump should meet the requirements of process working pressure, and the vacuum degree should be higher than that of vacuum equipment by half to one order of magnitude. (for example, the vacuum degree of 100 Pa (pressure) is required for the vacuum process, and the vacuum degree of the selected vacuum pump shall be at least 50 pa-10 PA). Generally, if the pressure is required to be higher than 3300pa, the water ring vacuum pump is preferred as the vacuum device. If the pressure is required to be lower than 3300pa, the water ring vacuum pump cannot be selected, and the rotary vane vacuum pump or higher vacuum level vacuum pump is selected as the vacuum obtaining device.

2、 Process required air extraction rate

The vacuum pump requires the air extraction rate (that is, the ability of the vacuum pump to discharge gas, liquid and solid under its working pressure), generally in m3 / h, L / s and m3 / min. The specific calculation method can refer to the following formula for self calculation and selection. Of course, the selection of vacuum pump is a comprehensive process, involving relevant experience and other factors.

S=(V/t)×ln(P1/P2)

Where: s is the pumping rate of vacuum pump (L / s)

V is the volume of vacuum chamber (L)

T time required to reach the required vacuum (s)

P1 is the initial pressure (PA)

P2 is the required pressure (PA)

3、 Determine the composition of the object to be extracted

1. Whether the object to be pumped is gas, liquid or particle. If the gas to be pumped contains water vapor or a small amount of particles and dust and other impurities, the rotary vane vacuum pump should be carefully selected. If the vacuum degree is required to be high, a filter device should be added to filter before using the rotary vane vacuum pump as a vacuum obtaining device.

2. To know whether there is corrosion (acid or alkaline, what is the pH value?) if there is acid-base corrosion or organic corrosion and other factors in the gas, it should be filtered or neutralized to select the rotary vane vacuum pump.

3. Is the object to be pumped contaminated with rubber or oil? For different media to be pumped, corresponding vacuum equipment should be selected. If there is a large amount of steam, particles and corrosive gas in the gas, it should be considered to install corresponding auxiliary equipment on the air inlet pipeline of the pump, such as condenser, filter, etc. (contact our corresponding technical engineers specifically).

4. Whether the noise, vibration and beauty of the vacuum pump affect the factory.

5. As the saying goes, cheap is not good. When purchasing vacuum pump and vacuum equipment, priority should also be given to the quality of equipment, transportation, maintenance and repair costs, etc.

The above is the best selection method of water ring vacuum pump. EVP vacuum pump manufacturers remind you that the selection of water ring vacuum pump should be in accordance with the standard as far as possible.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)