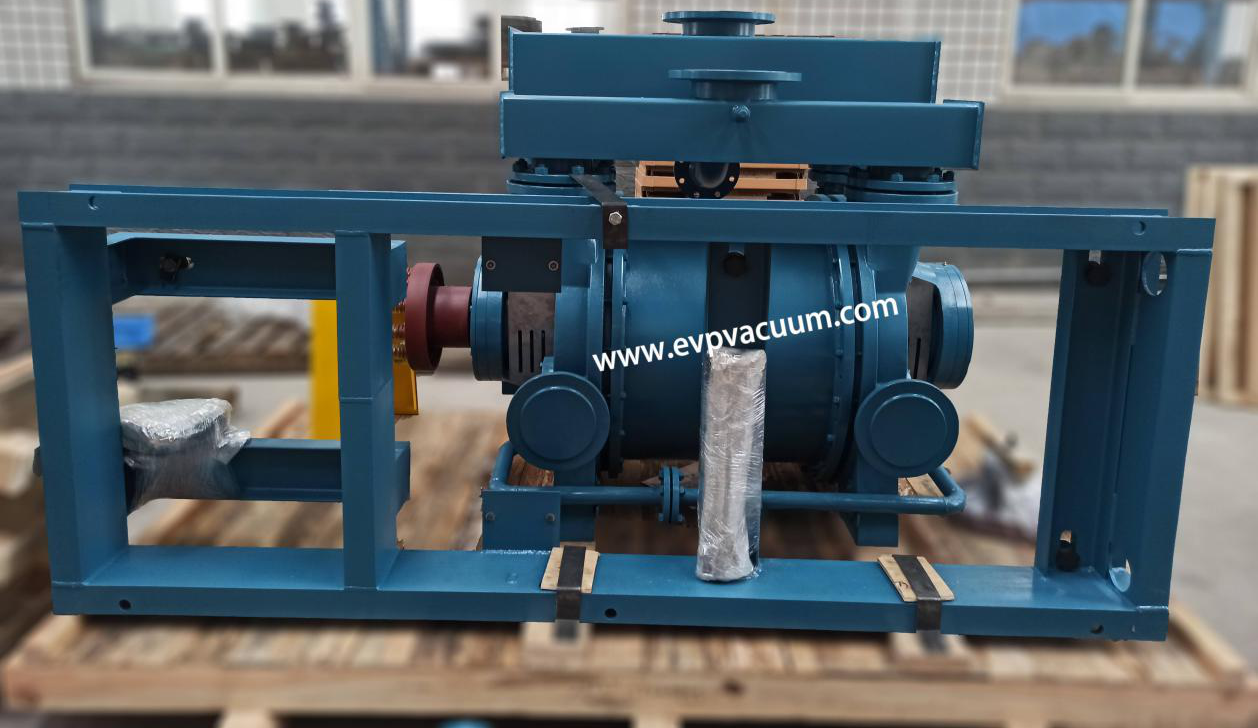

Water ring vacuum pump used in organic chemicals

Reaction principle and production process of common organic chemical – D-2-chloropropionyl chloride

1.Reaction Principle

Ethyl L-lactate and sulfoxide chloride were successively pumped into the reactor, heated for reaction, and ethyl 2-chloropropionate was obtained after distillation. Water, liquid alkali and ethyl 2-chloropropionate were successively pumped into the reactor, and ethanol was distilled after heat preservation reaction. The pH was adjusted to about 2.0 with hydrochloric acid, and dichloroethane was added for extraction. Dichloroethane was concentrated and recovered, and 2-chloropropionic acid was obtained by distillation. Then, 2-chloropropionic acid and thionyl chloride were pumped into a reactor, heated, and then distilled under reduced pressure to obtain the finished product d-2-chloropropionyl chloride. The main reaction equation is as follows

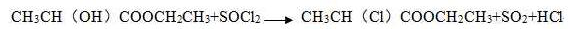

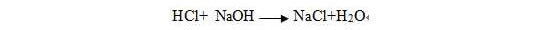

(i). Chlorination reaction

Primary reaction:

Secondary reaction:

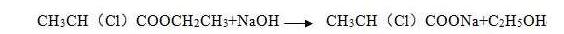

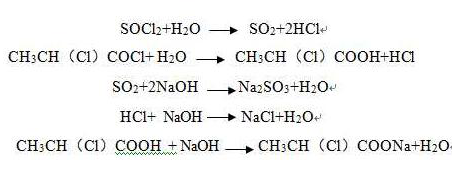

(ii). Hydrolysis reaction

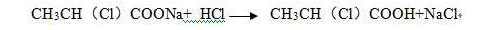

(iii). Adjust PH

Primary reaction:

Secondary reaction:

(iv). Acylation reaction

Primary reaction:

Secondary reaction:

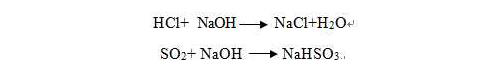

(v). Alkali absorption

II.Technological process

(1) Chlorination reaction

Ethyl L-lactate was pumped into a dry and clean reactor, cooled to below 20 ℃, and excessive sulfoxide chloride was added. After dropping, the temperature was raised to above 80 ℃, and the reaction was kept at normal pressure for 3 hours to generate ethyl 2-chloropropionate. The waste gas generated from chlorination reaction was absorbed by three-stage falling film absorption tower and then absorbed by alkali solution, and the unabsorbed waste gas was discharged at high altitude.

(2) Vacuum distillation

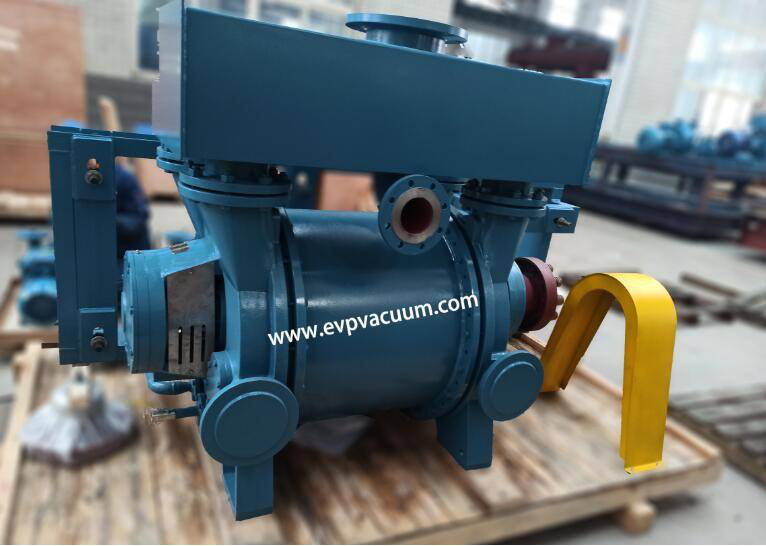

The chlorination reaction product is transferred to the distillation kettle for vacuum distillation. The high boiling condensate is mainly ethyl 2-chloropropionate, which is sent to the hydrolysis kettle. The low boiling condensate mainly contains thionyl chloride, which is reused for chlorination reaction. The distillation residue is dangerous solid waste, which is entrusted to a qualified unit for safe disposal. The distillation waste gas discharged from the water ring vacuum pump is discharged at high altitude, and the distillation waste water discharged from the water ring vacuum pump is sent to the wastewater treatment Device.

(3) Hydrolysis

First, add water and excess 30% liquid alkali into the reactor, drop ethyl 2-chloropropionate under normal temperature and pressure, keep for 2-3 hours, and hydrolyze to produce sodium 2-chloropropionate and ethanol.

(4) The hydrolysate is pumped into the distillation kettle by distillation condensation, and ethanol is recovered by distillation condensation. The liquid from the distillation kettle is sent to the extraction kettle, and the distilled uncondensated gas is discharged at high altitude after water washing. The washing wastewater will be generated during the water washing process and sent to the wastewater treatment unit.

(5) Extraction

After the distillation kettle liquid is pumped into the extraction kettle, the pH is adjusted to 2.0 with 36% hydrochloric acid, and dichloroethane is added for extraction. After the extraction liquid is stratified, the organic phase is sent to the concentration kettle, and the water phase mainly contains sodium chloride, water and organic matter, which is sent to the salt making process.

(6) In salt making, the extracted water phase is evaporated and concentrated to remove part of water and organic matter. The condensed waste water from the evaporation gas condensation process is sent to the waste water treatment device, and the uncondensated gas is discharged at high altitude. The concentrated liquid is evaporated and concentrated for crystallization after adsorption by activated carbon, and the by-product sodium chloride is obtained by drying the crystal. Waste activated carbon will be produced in the process of activated carbon adsorption, condensed waste water and non condensed waste gas will be produced in the process of evaporation concentration crystallization condensation, and drying waste gas will be produced in the process of drying. The waste activated carbon will be entrusted to a qualified unit for safe disposal. The condensed waste water will be sent to the wastewater treatment unit, and the non condensed waste gas and drying waste gas will be directly discharged.

(7) The extracted organic phase is pumped into a concentration kettle for concentration and recovery of dichloroethane, and the concentrated mother liquor is transferred to a distillation kettle. The uncooled waste gas produced in the process of concentration and recovery is discharged at high altitude after being adsorbed by the activated carbon adsorption device. The activated carbon adsorption device will produce waste activated carbon and desorbed condensed waste liquid, which are all entrusted to a qualified unit for safe disposal.

(8) Rectification

During the concentration and recovery process, the kettle liquid is pumped into the distillation kettle for vacuum distillation, and the high boiling condensate is 2-chloropropionic acid, which is sent to the acylation reactor. The distillation residue s4-5 and low boiling condensate S4-6 are entrusted to the qualified unit for safe disposal. The distillation waste gas discharged from the water ring vacuum pump is discharged at high altitude, and the distillation waste water discharged from the water ring vacuum pump is sent to the wastewater treatment unit.

(9) Acylation reaction

The 2-chloropropionic acid and excess sulfoxide chloride obtained by distillation are pumped into the reactor, stirred and heated to 50-60 ℃, and the reaction is kept under normal pressure. After the reaction, they are pumped to the distillation kettle. The waste gas from acylation reaction and chlorination reaction are absorbed by three-stage falling film absorption tower and then by alkali solution, and the unabsorbed waste gas is discharged at high altitude.

(10) Vacuum distillation

After the completion of acylation reaction, the product is pumped into the distillation kettle for vacuum distillation. The high boiling condensate is product d-2-chloropropionyl chloride, and the low boiling condensate is mainly thionyl chloride, which is reused in the acylation reaction process. The distillation residue is hazardous waste, which is entrusted to a qualified unit for safe disposal. The distillation waste gas discharged from the water ring vacuum pump is discharged at high altitude, and the distillation waste water discharged from the water ring vacuum pump is sent to the wastewater treatment unit.