2BE1 pump instruction

1、2BE1 pump overview

2BE1 series liquid ring vacuum pump is a single-stage acting vacuum pump produced by our company with advanced technology. It has many advantages, such as no friction surface, no oil lubrication, compact structure, reliable operation, convenient use and maintenance, wide selection range, etc. it is mainly used to vacuum pump gas without particles. The working medium is normal temperature clean water, and other medium such as acid and alkali can also be used as working fluid for special requirements. The range of gas volume is 4.8-450 m3 / min, the ultimate vacuum is 33 mbar or 160 mbar, and the efficiency is 40-65%. It is widely used in power, chemical, pharmaceutical, coal, sugar and other industries.

Note: if it is used in coal mine, it must be equipped with explosion-proof motor of corresponding grade, and monitoring and safety equipment must be installed in strict accordance with the requirements of coal mine safety regulations.

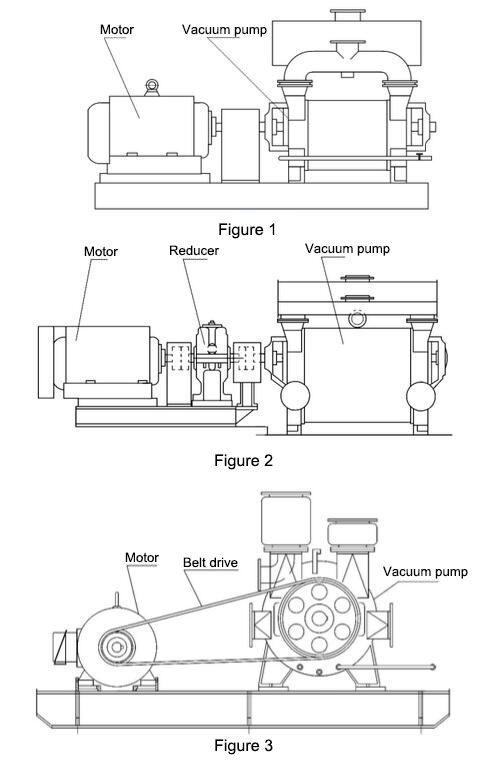

There are 15 varieties of 2BE1 series, each of which has 5-7 total selection speed. There are three matching forms of motor direct coupling, reducer and belt drive. See Figures 1, 2 and 3.

Note: if required by the user, the reducer can be connected to thin oil station for lubrication

2、 Single pump and complete set model representation method

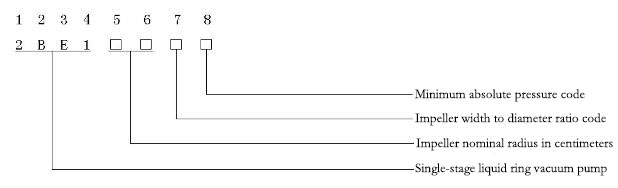

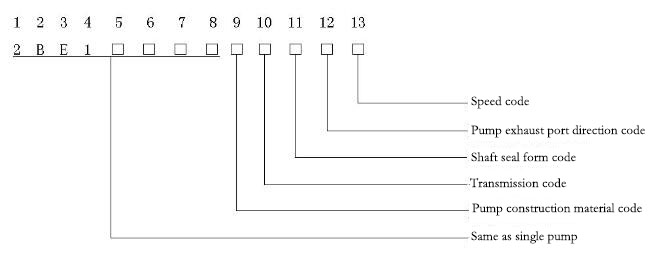

1. Single pump model representation method

2. 2BE1 type complete set number representation method

Notes to the method of complete set

| Serial number | Code | Significance | |||||||||||

| 7 | 3 | Impeller width-to-diameter ratio is 1 | |||||||||||

| 5 | Impeller width-to-diameter ratio is 1.2 | ||||||||||||

| 6 | Impeller width-to-diameter ratio of 1.2 with intermediate bulkhead | ||||||||||||

| 8 | 0 | Minimum suction absolute pressure 33mbar | |||||||||||

| 1 | Minimum suction absolute pressure 160mbar | ||||||||||||

| 9 | B | Grey cast iron | |||||||||||

| E | Gray cast iron-nickel chromium stainless steel | ||||||||||||

| F | Nickel chromium stainless steel | ||||||||||||

| 10 | D | Motor direct drive | |||||||||||

| V | Motor belt drive | ||||||||||||

| G | Motor reducer transmission | ||||||||||||

| 11 | 3 | External water supply packing seal | |||||||||||

| 4 | Internal water supply packing seal | ||||||||||||

| 12 | No words | Pump exhaust | |||||||||||

| L | Pump horizontal exhaust | ||||||||||||

| 2BE1 | 2BE1 102/3 | 2BE1 151/3 | 2BE1 202/3/4 | 2BE1 252/3 | 2BE1 303/5 | 2BE1 353 | 2BE1 355/6 | 2BE1 403/5 | 2BE1 405/6 | 2BE1 503/5 | 2BE1 605 | 2BE1 705 | |

| A | 1300 | 1300 | 880 | 660 | 472 | 372 | 372 | 330 | 330 | 266 | 236 | 210 | |

| B | 1450 | 1450 | 980 | 740 | 500 | 420 | 420 | 372 | 372 | 298 | 266 | 236 | |

| C | 1625 | 1625 | 1100 | 820 | 530 | 472 | 472 | 420 | 420 | 330 | 298 | 266 | |

| D | 1750 | 1750 | 1170 | 880 | 590 | 500 | 500 | 472 | 472 | 372 | 330 | 298 | |

| E | 660 | 530 | 530 | 530 | 530 | 420 | 372 | 330 | |||||

| F | 710 | 590 | 590 | 565 | 565 | 472 | 398 | ||||||

| G | 740 | 660 | 660 | ||||||||||

| H | 790 | ||||||||||||

3、 2BE1 pump working principle, structural characteristics and structure

1. How it works liquid ring vacuum pump

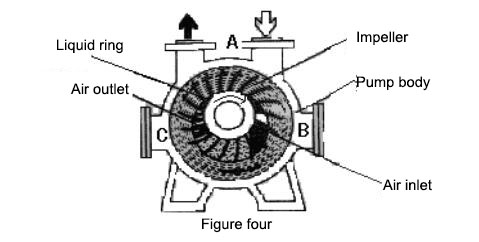

The impeller is installed in the vacuum pump eccentrically, and a certain height of water is injected into the vacuum pump before starting. When the impeller rotates, the centrifugal force acts on the impeller to form a rotating liquid ring inside the vacuum pump body wall, and the blade and distributor at both ends form a closed cavity. During the rotation of the first half turn (at this time through the suction hole), the volume of the sealed cavity gradually expands, and the gas is inhaled by the suction hole. During the second half rotation (passing through the exhaust hole at this time), the volume of the sealed cavity is gradually reduced, and the gas is discharged from the exhaust hole, as shown in Figure 4.

In order to maintain a constant liquid ring, it is necessary to continuously supply water to the vacuum pump during operation.

2. Liquid ring vacuum pump structural features

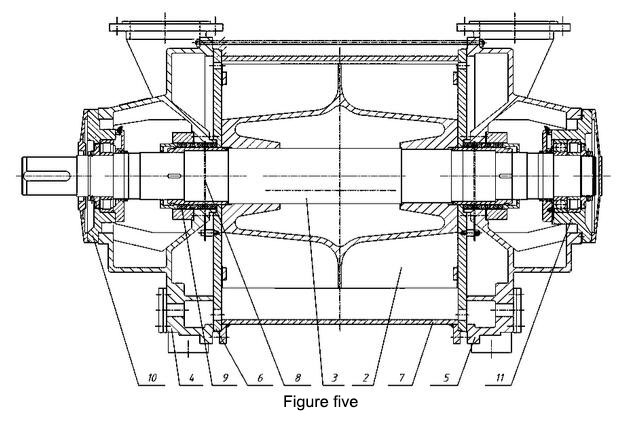

The series liquid ring vacuum pump adopts axial suction and exhaust structure. The single vacuum pump is mainly composed of vacuum pump body (oval), impeller, drive side distributor, non drive side distributor, side cover, automatic drain valve and other parts. As shown in Figure 5, the impeller and main shaft are heat jacketed together. The side cover is separated from the distributor. The side cover is equipped with an observation hole. The vacuum pump body can rotate to meet the different requirements of the user.

1. Pump body 2, impeller 3, vacuum pump shaft 4, front side cover 5, rear side cover 6, front distributor 7, rear distributor 8. Valve plate part 9, shaft seal part 10, front bearing part 11, rear bearing part

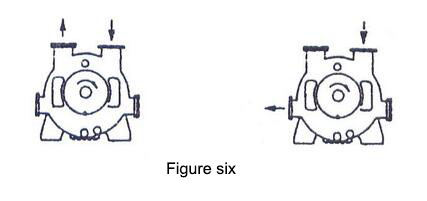

For 2be130-70 liquid ring vacuum pump, its main shaft can be extended by two shafts, that is, one motor can be connected in series with two to four liquid ring vacuum pumps at the same time. According to the user’s requirements, its air inlet and exhaust holes can be connected by side connection or top connection (see Figure 6). The filling material can also be supplied by external water according to the user’s needs.

3, Liquid ring vacuum pump structure

3.1 impeller: according to the minimum absolute pressure of vacuum pump suction, it can be divided into two structural forms: Casting and welding parts. Generally speaking, the impeller with “3” structure (such as 103-403) uses casting parts, and the impeller with “5” structure (such as 355-705) uses welding parts. The impeller materials can be qt40-17, zgal9-4-4-2, 1Cr18Ni9 and 1cr18ni12mo2ti according to the user’s needs.

3.2 shaft: 2be110-25 is generally 2Cr13, 2be130-40 is made of 45 × steel, and 2be135-70 is 42CrMo.

The shaft seal can be in two forms of packing seal and mechanical seal. In order to prevent the shaft from being damaged by packing, the chromium rigid shaft sleeve is used.

3.3 vacuum pump body: elliptical structure, made of C3 steel. In special cases, 1cr18ni2mo2ti can also be used, and the vacuum pump body can rotate.

3.4 distributor: 2be110-25 is supported by HT200, 2be130-70 is made of C3 steel, which can be replaced by 1cr18ni12mo2ti as required by users.

3.5 side cover: it is made of HT200 or nickel chromium nodular iron or stainless steel. The side cover is equipped with an automatic drain valve to remove excessive water before starting. The side cover is equipped with an inspection cover plate to check the condition of the working room.

3.6 bearing parts: a cylindrical roller bearing is installed on the driving side and non driving side respectively to bear radial force. In addition, a centripetal ball bearing is arranged on the non driving side to bear axial force.

3.7 automatic drain valve: made of HT200, it can automatically discharge the excess water in the vacuum pump to make the vacuum pump work better.

3.8 coupling: transmit power.

4、2BE1 pump of performance parameters and spectrum

|

Model |

Minimum inhalation absolute

Pressure, hPa

|

Rotating speed,

rpm

|

Gas at suction pressure 400hPa

Volume, ms / h

|

Most canine shaft power,

KW

|

Impeller nominal diameter

, mm

|

|

2BE1103-0 |

33 |

1300 |

288 |

7. 0 |

200 |

|

2BE1153-0 |

33 |

1100 |

432 |

10.6 |

300 |

|

2BE1203-0 |

33 |

790 |

858 |

21.2 |

400 |

|

2BE1253-0 |

33 |

590 |

1698 |

37.2 |

500 |

|

2BE1303-0 |

33 |

472 |

2322 |

52.5 |

600 |

|

2BE1353-0 |

33 |

372 |

3240 |

64. 5 |

700 |

|

2BE1403-0 |

33 |

330 |

4710 |

102.0 |

800 |

|

2BE1305-1 |

160 |

472 |

2778 |

56.8 |

600 |

|

2BE1355-1 |

160 |

372 |

3612 |

71.5 |

700 |

|

2BE1356-1 |

160 |

372 |

3612 |

71.5 |

700 |

|

2BE1405-1 |

160 |

330 |

5484 |

105 |

800 |

|

2BE1406-1 |

160 |

330 |

5484 |

105 |

800 |

|

2BE1505-1 |

160 |

266 |

7146 |

136.0 |

1000 |

|

2BE1506-1 |

160 |

266 |

7146 |

136.0 |

1000 |

|

2BE1605-1 |

160 |

236 |

10560 |

196.0 |

1200 |

|

2BE1606-1 |

160 |

236 |

10560 |

196.0 |

1200 |

|

2BE1705-1 |

160 |

197 |

15300 |

285 |

1400 |

|

2BE1706-1 |

160 |

197 |

15300 |

285 |

1400 |

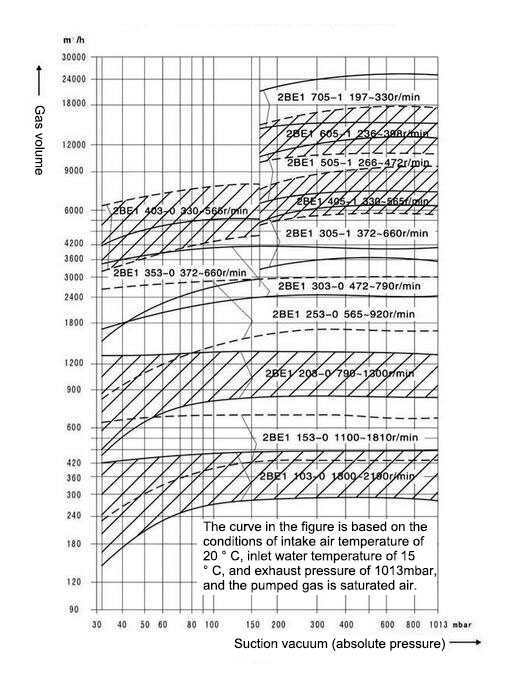

1. The above performance data is based on the conditions of inlet air temperature 20 ℃, inlet water temperature 15 ℃, and exhaust pressure 1013 mbar.

2. Some pumps, such as 2be1355 / 6-1, 2be1355-1 without intermediate diaphragm, 2be1356-1 with intermediate diaphragm, the vacuum pump foundation installation size is the same, both sides of the vacuum pump body can work under different suction absolute pressure conditions when the vacuum pump is running.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)