Oil diffusion pump use and maintenance

In today’s vacuum related industries, oil diffusion pump has an irreplaceable position. It has the characteristics of no selectivity to the gas, high pumping rate, simple structure, no mechanical transmission, no friction and convenient operation and maintenance.

No mechanical transmission, no friction? So how does the oil diffusion pump work?

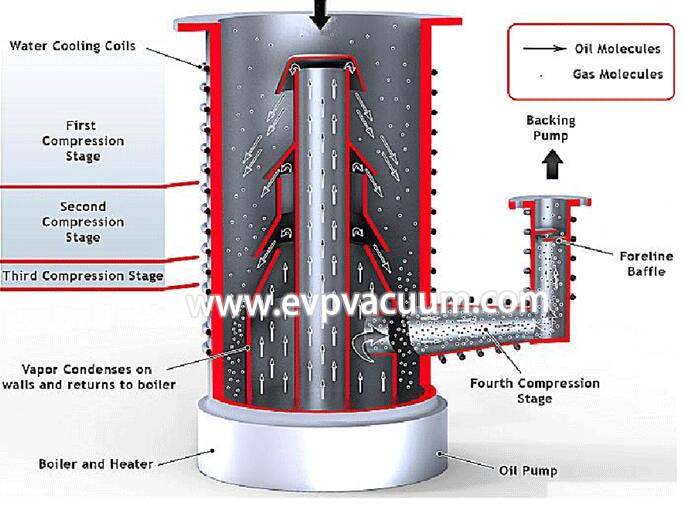

In fact, the pumping principle of oil diffusion pump is to use the high-speed oil steam flow mixed with the extracted gas for energy exchange to achieve the pumping effect. The main performance (parameter) indexes representing the technical level of oil diffusion pump are: limit pressure, pumping rate, critical pre stage pressure, pump fluid return rate, mean time between failure, etc.

When the oil of the oil diffusion pump is heated by the electric furnace, the oil vapor is ejected downward along the guide pipe through the umbrella nozzle. Because there is a vacuum (1 ~ 10-1 PA) provided by mechanical pump outside the nozzle, the oil vapor can be ejected for a long distance to form a jet moving towards the outlet. The jet finally collides with the pump wall cooled by cooling water and condenses into liquid and flows back to the evaporator, that is to say, the repeated circulation of oil evaporation, injection and condensation is used to realize air extraction. Once the gas molecules entering the pump from the inlet port fall into the steam stream, they will get momentum of downward movement and fly down. Because of the high flow rate (about 200m / s), high vapor density and high molecular weight (300-500) of diffusion pump oil, the jet can effectively remove gas molecules. The gas molecules are taken to the outlet and pumped away by a mechanical pump.

Combined with the above oil diffusion pump structure schematic diagram, is it easy to understand?

What should be paid attention to in daily use and maintenance of oil diffusion pump?

1. During the operation of oil diffusion pump, the cooling water must be unblocked. After stopping heating, it must be ensured that the working fluid of the pump has been completely cooled before turning off the cooling water.

2. When the pump stops working, the vacuum state shall be kept in the pump to avoid the deterioration of pump oil.

3. The extracted gas should be dry, corrosion-free and dust-free.

4. If the pump is not used for the time being, the vacuum state should be maintained during storage to avoid oil pollution and corrosion of various parts. And blow the remaining water in the cooling water jacket. The room temperature should be between 10 ℃ and 40 ℃.

Oil diffusion pump in normal operation in case of sudden performance deterioration, should first check whether the heater is normal. After long-term operation, the performance of the pump will gradually deteriorate, and it should be regularly overhauled.

1. Whether the pump oil is reduced or oxidized, add oil or replace the pump oil according to the corresponding requirements.

2. The parts and pump cavity shall be cleaned with aviation gasoline, then cleaned with silk dipped in ether or acetone, and dried at 80 ℃ ~ 100 ℃ or dried with electric hair dryer.

3. After treatment, assemble according to the sequence, keep the pump core and pump bottom vertical and concentric with the pump cavity, and adjust the nozzle clearance at all levels according to the original requirements.