Claw vacuum pump in chemical industry

There is no liquid in the pump chamber of dry vacuum pump, which can be pumped to several PA from the atmosphere. Dry vacuum pump has been replaced by oil sealed mechanical pump in semiconductor industry. The limit pressure of (1 ~ 100) Pa is obtained for chemical vapor deposition and chip etching. In the past, inert fluorine oil was used to lubricate oil seal mechanical pumps in semiconductor industry to prevent corrosive gas from eroding oil. However, fluorine oil is very expensive and maintenance cost is also very high.

Using dry vacuum pump, there is not only no lubricating oil in the pump, but also no problem of waste liquid treatment. However, there is no oil in the pump chamber, which makes the gap inside the pump chamber unable to keep sealing, and also loses the heat transfer medium used to control the temperature, which brings great challenges to the dry vacuum pump.

The early dry-type vacuum pump is composed of several stages of roots rotor or claw rotor in series. They have no contact in the pump cavity. Two parallel rotor shafts are driven by synchronous gears. Since there is no liquid in the pump cavity, the internal clearance should be kept as small as possible to reduce the gas backflow. However, this small gap is very sensitive to the accumulation of process particles. At present, the solution to this problem is to fill inert gas into the pump inlet to wash it off, or dilute the condensable corrosive gas with inert gas.

The successful application of dry-type vacuum pump in semiconductor industry also encourages dry-type vacuum pump manufacturers to introduce dry-type vacuum pump into chemical industry. Although dry-type vacuum pump is expensive, its operation cost is low, especially there is no waste liquid treatment problem, which is very beneficial to environment and health. At present, there are many kinds of dry pumps, including scroll pump, diaphragm pump, dry vane pump, roots dry pump, claw type dry pump and screw vacuum pump. Roots type dry pump, claw type dry pump and screw vacuum pump play a leading role in the application of chemical industry.

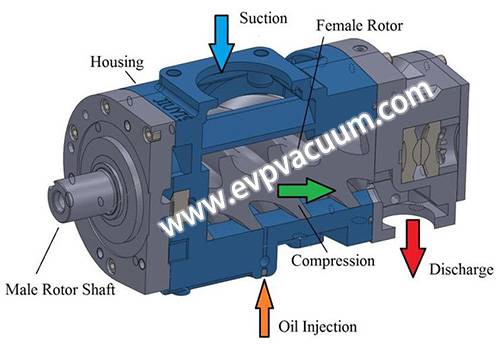

Claw type vacuum pump has been successfully researched in 1930 and used in compressor industry for the first time. The characteristic of claw type rotor is high compression ratio under high pressure. The claw rotor also has two functions: one is used to intercept, transport and compress gas; the other is to open and close the suction and exhaust ports at appropriate time like a valve. At present, the design structure of this kind of vacuum pump is mostly composed of the first stage roots rotor and the third stage claw rotor in series. The roots rotor is used as the high vacuum stage, and the claw rotor is used as the compression exhaust stage, as shown in the figure.

When the claw type dry pump was used in the fields of semiconductor sputtering, etching, ion implantation and PCVD film preparation in the early stage, due to the formation of a large number of small particles or corrosive media generated by reaction in the process, inert gas can be introduced into the pump port for cleaning to prevent the deposition of small particles in the pump chamber and reduce the concentration of corrosive gas. Claw type vacuum pump has been used in evaporation, distillation, drying, concentration and other fields in chemical industry. The limit pressure of the claw type vacuum pump is (1 ~ 10) Pa and the pumping speed is (25 ~ 140) l / s.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)